Air suspension track running equipment

A rail operation and air suspension technology, applied in the field of transportation, can solve the problems of unsuitability for widespread promotion and application, complicated maintenance, high noise, etc., to avoid overload drawbacks, easy to drive, and reduce friction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

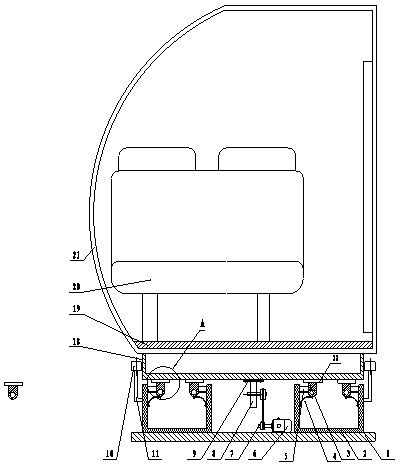

[0017] See Figure 1~ Figure 4 , The composition of the present invention includes a suspension mechanism, a drive mechanism, a sealing mechanism and a transport carrier. The suspension mechanism is composed of two sets of left-right symmetrical high-pressure air chambers and a track base 1. The high-pressure air chamber is composed of a high-pressure gas chamber 2, a lubricated airtight slide rail 3 and a slide rail support frame 5; the high-pressure gas chamber The cross-sectional structure of the chamber is a U-shaped groove; one end of the slide rail support frame 5 is hinged with the lubricated airtight slide rail 3, and the other end is hinged with the inner wall of the high-pressure gas chamber 2; the high-pressure air chamber is fixed on the track base 1.

[0018] Referring to Fig. 1, the driving mechanism in the composition of the present invention comprises a driving motor group, a reduction mechanism 7, a friction wheel 8 and a friction plate 9, and the driving moto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com