Automatic rolling forming machine for ceramic container clay blanks

A technology of rolling forming machine and ceramic container, applied in the direction of pressing roller, etc., can solve the problems of easy rupture, low production efficiency, large difference in size of ceramic container mud, etc., and achieve the effect of not easy to rupture and high production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below in conjunction with accompanying drawing and embodiment:

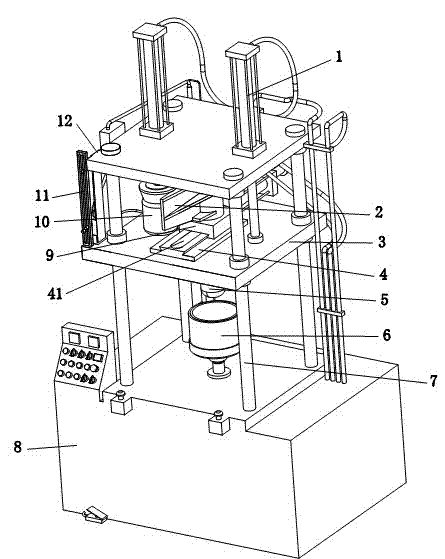

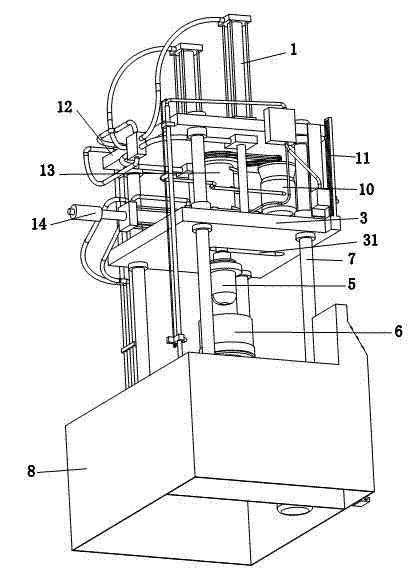

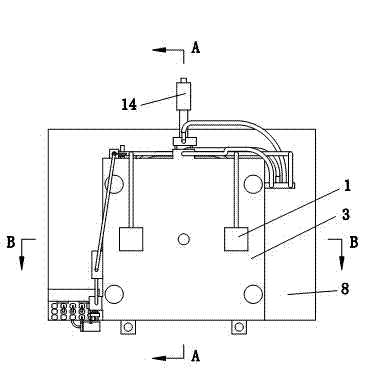

[0016] Such as Figures 1 to 5 As shown, it is a kind of automatic rolling forming machine for ceramic container mud base, including frame 8, ceramic container mud base mold 6 and forming rotor 5, the position of forming rotor 5 is the same as that of ceramic container mud base mold 6 Corresponding; The feature of the present invention is: also comprise the first motor 17 that is located at described frame 8 below, drive it to rotate and the first runner 16 with rotating shaft by the first motor 17, the rotating shaft of the first runner 16 and all The ceramic container mud mold 6 is connected; it also includes more than two guide posts 7 fixed on the frame 8, the first mounting plate 3 that is sleeved on the guide posts and can slide up and down, and is located on the first mounting plate. The slide rail 4 is provided with an elongated hole 31 on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com