Near infrared lens

A near-infrared and lens technology, applied in the field of near-infrared lenses, can solve the problems of non-conformity, complex lens structure, larger lens volume, etc., and achieve the effect of athermalization and excellent optical performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

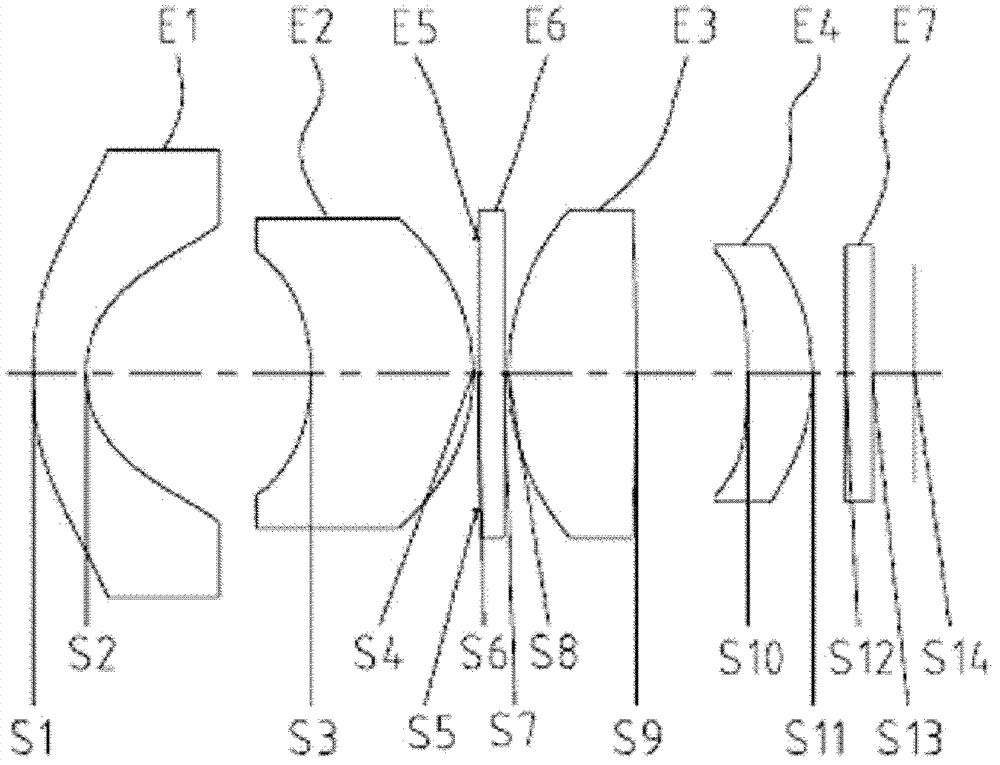

[0066] The focal length of each eyeglass of the near-infrared lens of embodiment 2 is as follows:

[0067] f1=-6.80; f2=23.53; f3=6.53; f4=8.47; f=2.27.

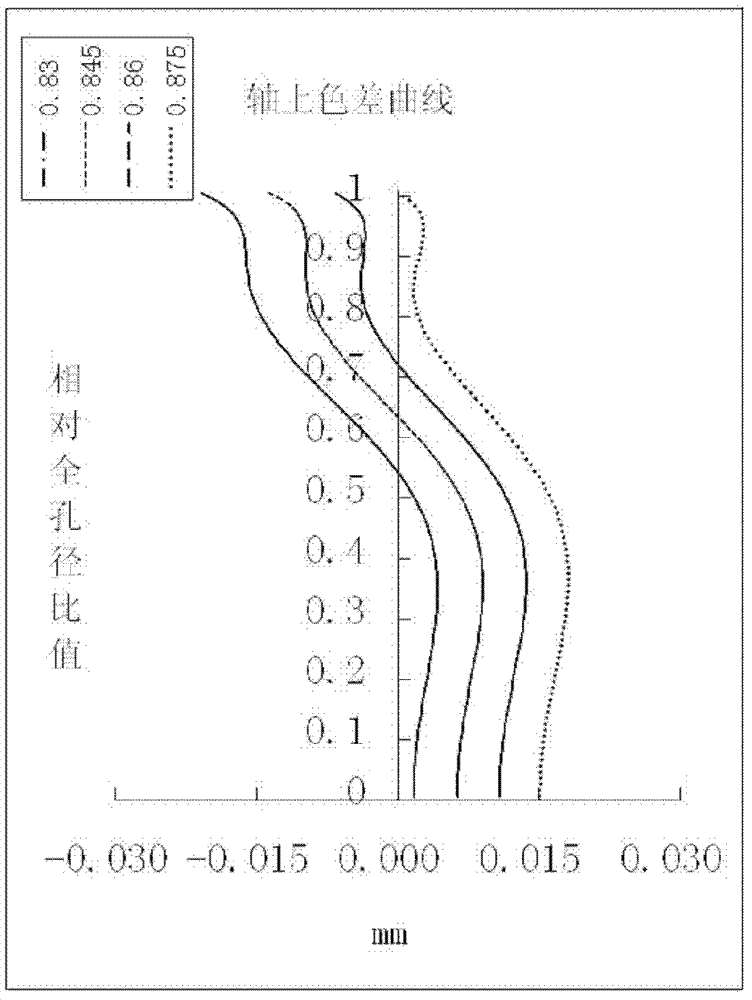

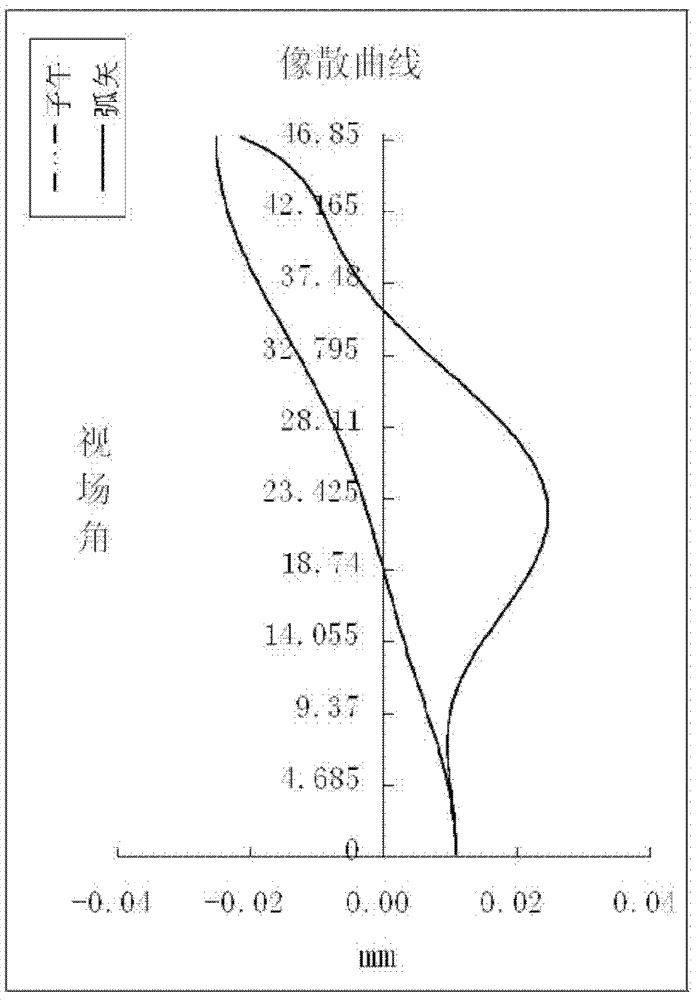

[0068] The near-infrared lens of Example 2 also adopts a glass-plastic mixed structure to overcome the heat dissipation difference. And the lens satisfies the following expression:

[0069] dn1 / dt=dn2 / dt=-1.022×10 -4 , dn3 / dt=4.65×10 -6

[0070] Table 3 and Table 4 list the relevant parameters of the lenses in Example 2, including the surface type and radius of curvature of the lens surface, as well as the thickness, material, effective diameter and conic coefficient of each lens.

[0071] System parameters: 1 / 4 "photosensitive device aperture value 1.0

[0072] table 3

[0073] Surface number S

[0074] Table 4 shows the aspheric high-order coefficients A4, A6, A8, A10, A12, A14, and A16 of the aspheric lenses of Example 2.

[0075] Table 4

[0076] Face number

[0077] S10

[0078] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com