Manufacturing method of sewing-free umbrella

A production method and umbrella surface technology, which are applied to umbrellas, clothing, walking sticks, etc., can solve the problems of reducing the service life of the umbrella, taking time and effort, affecting the production efficiency, etc., and achieving the effect of improving the production efficiency and making the umbrella structure simple.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order for those skilled in the art to further understand the features and technical content of the present invention, please refer to the following detailed description and accompanying drawings of the present invention.

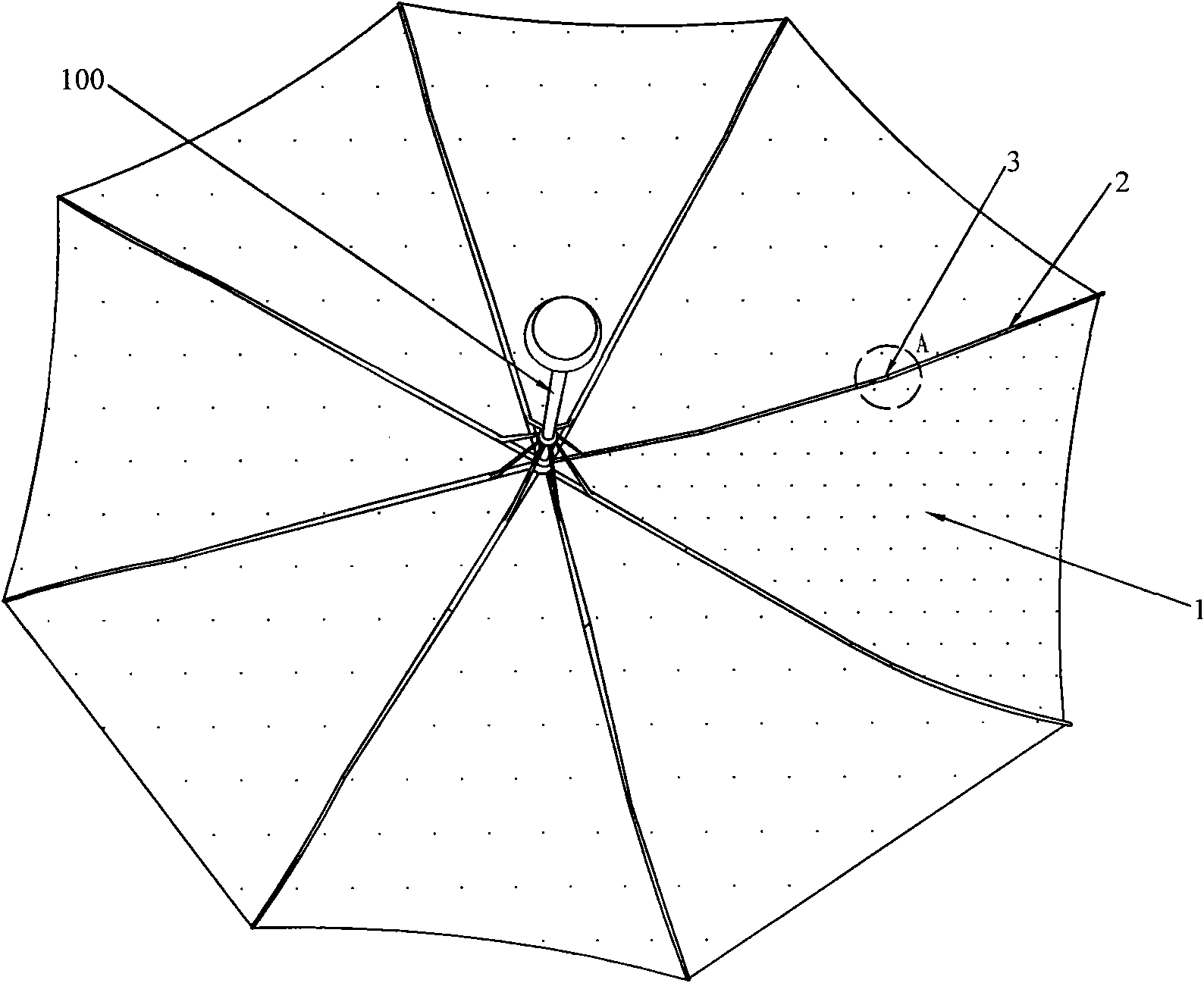

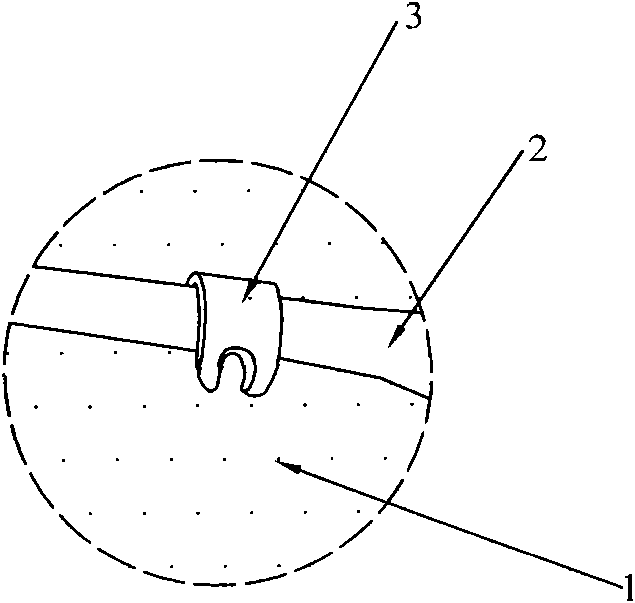

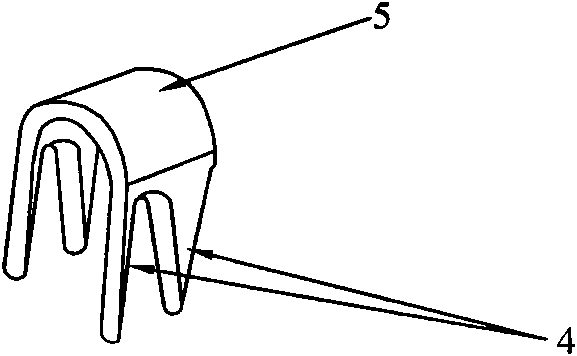

[0023] see Figure 1 to Figure 7 As shown, the present invention provides a method for making a sewing-free umbrella, including the steps of connecting the umbrella cover 1 to the umbrella frame 2 for supporting the umbrella cover, wherein the steps are as follows: (1) : provide the fixing part 3, the longitudinal section of the fixing part is roughly U-shaped, and has a closed end for clipping on the umbrella frame and an open end for piercing the umbrella cover, the fixing part is open The end faces on both sides corresponding to each other each have at least one pair of teeth 4 used to wear through the umbrella surface and lock it on the umbrella frame; On the skeleton, the teeth of the open end are used to penetrate the umbrella surface and be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com