Method for calibrating direction of three-probe start sensor

A calibration method and three-probe technology, applied in measurement devices, instruments, etc., can solve problems such as high accuracy requirements, failure to meet calibration accuracy requirements and measurement accuracy requirements, focusing errors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The specific embodiment of the present invention will be described in detail below in conjunction with the flowchart.

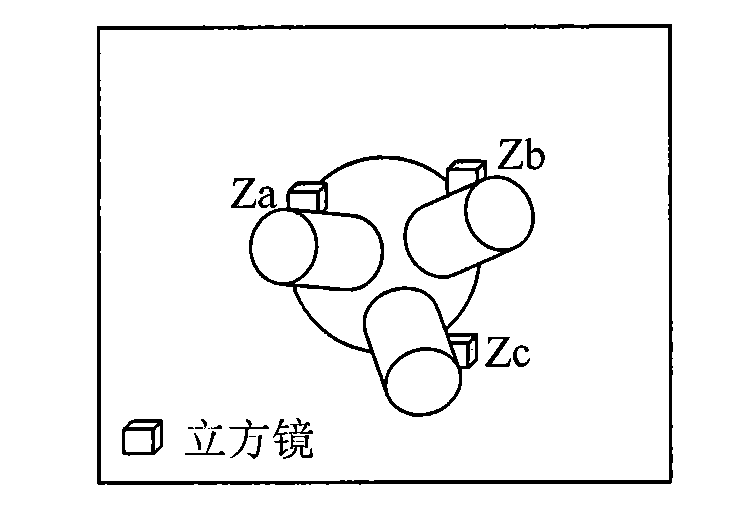

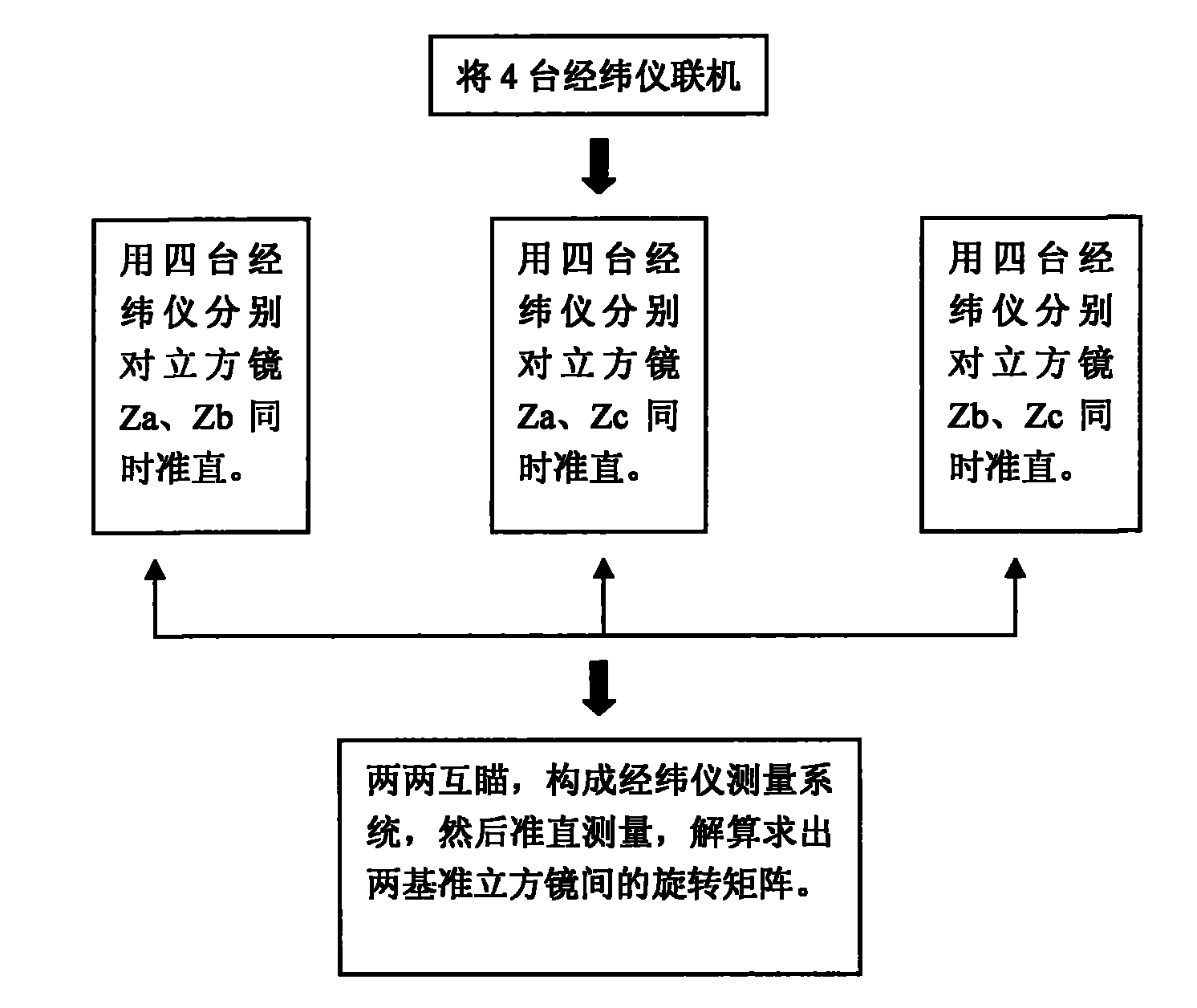

[0012] Depend on figure 2 Shown, the present invention is in concrete implementation, and three cube mirrors Za, Zb, Zc are combined mutually two by two earlier, promptly cube mirror Za, Zb, cube mirror Za, Zc, three-dimensional mirror Zb, Zc are combined into three mutually. Group, first connect the four theodolites online, and then use the four theodolites to collimate the two cubic mirrors combined with each other at the same time, and then aim at each other two by two, solve the rotation matrix between the two reference cube mirrors, specifically Achieved by the following steps:

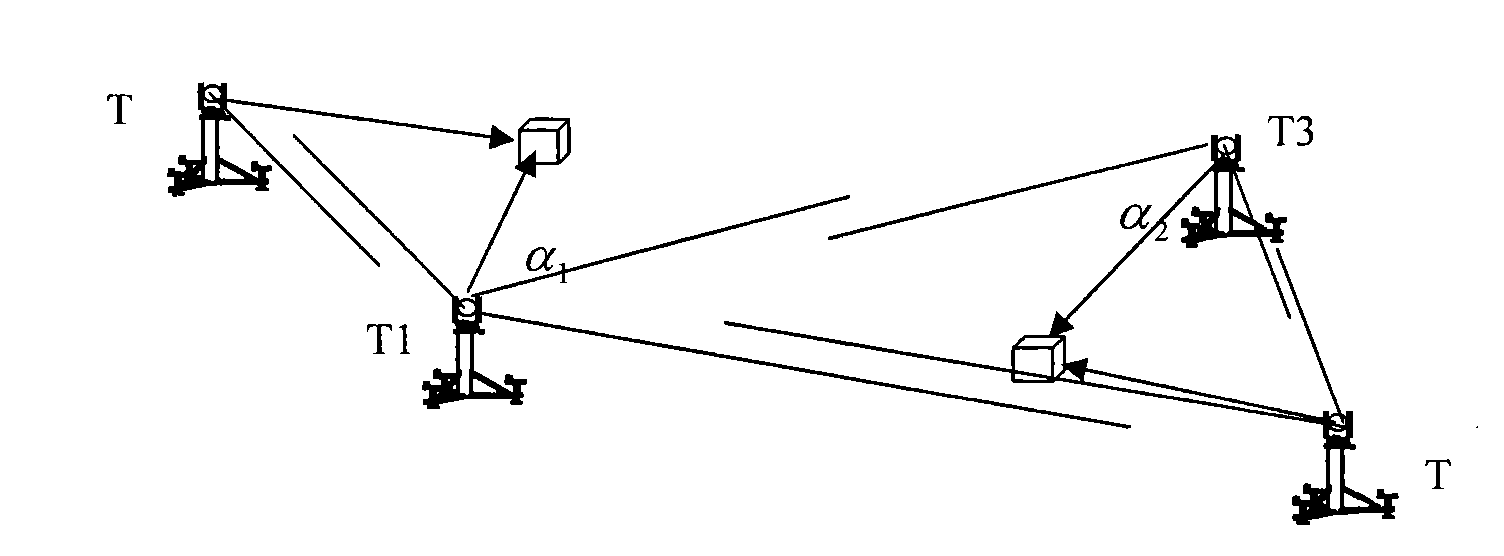

[0013] 1. Let 3 cubic mirrors be Za, Zb, Zc respectively, and 4 theodolites be T 1 , T 2 , T 3 , T 4 , put the three-probe Xingmin in a fixed position, do not move, and use 4 theodolites to align the 3 cubic mirrors that are collimated in pairs, that is, use 4 theod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com