Water yield adjusting mechanism of instant electric heating kettle

A technology of electric kettle and water output, which is applied in the direction of water boiling utensils, cooking utensils, kitchen utensils, etc. It can solve the problems of inaccurate control of water output, poor operation flexibility, internal backflow leakage, etc., and achieves ingenious and reliable design. High performance and stable water output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

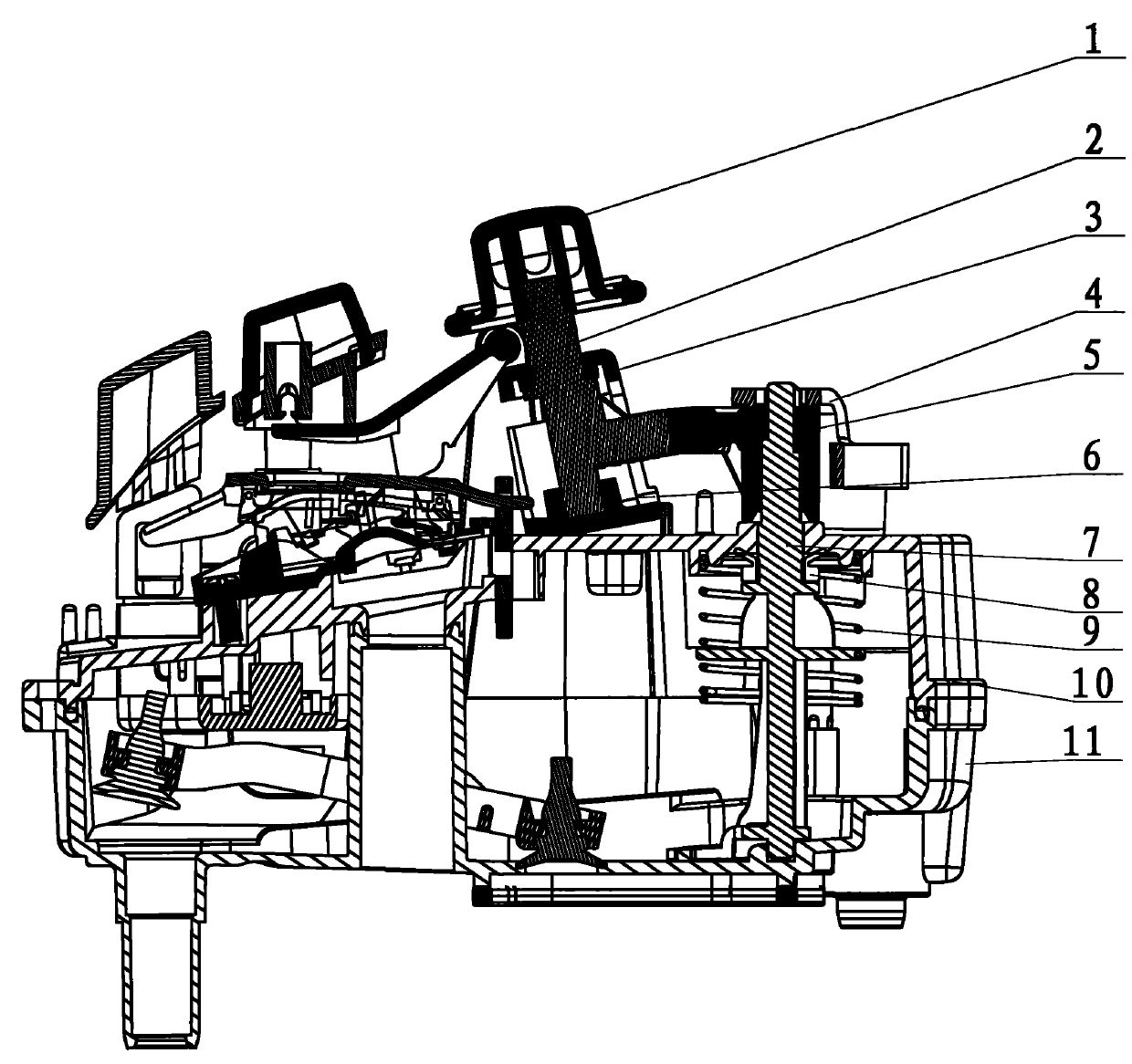

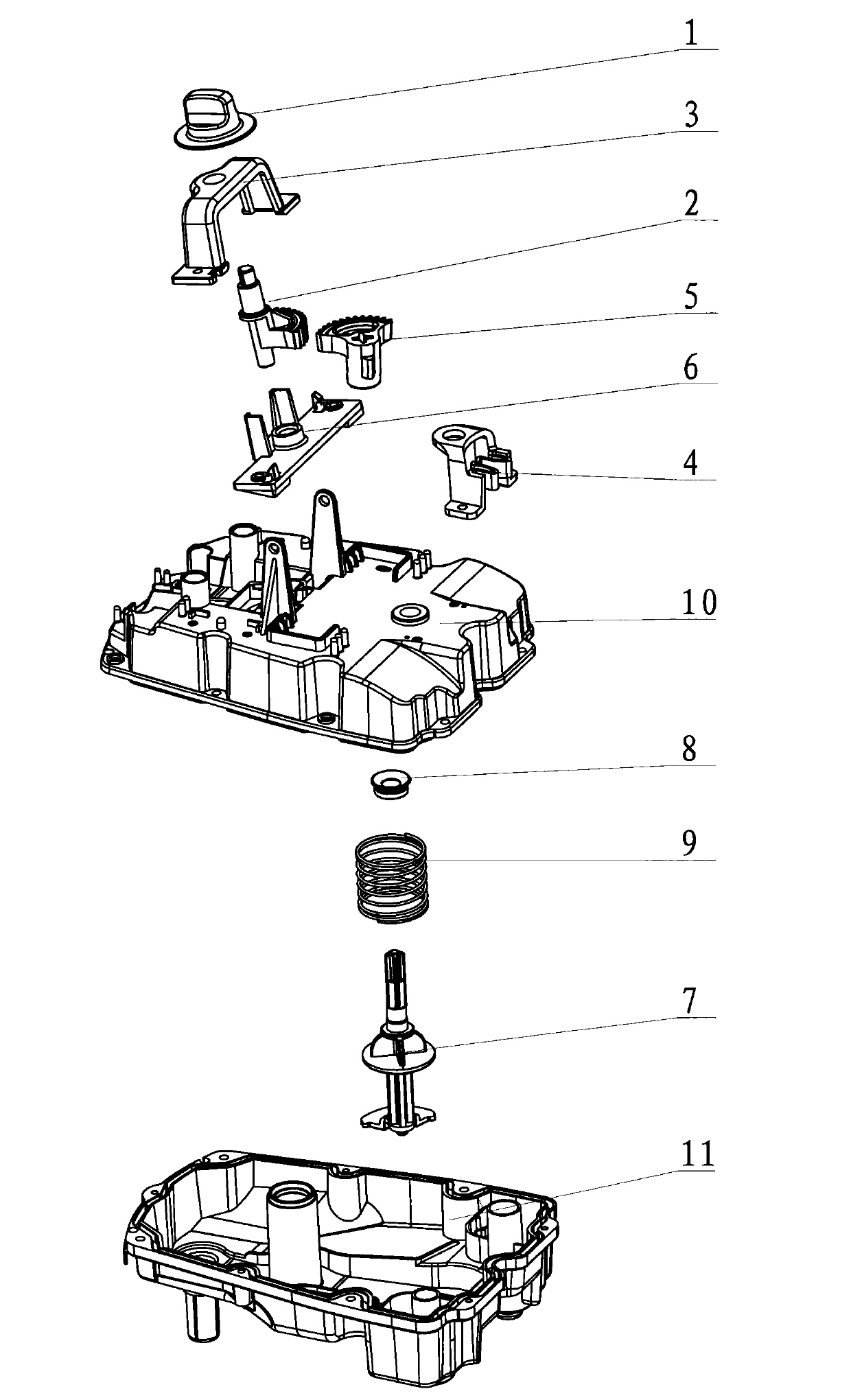

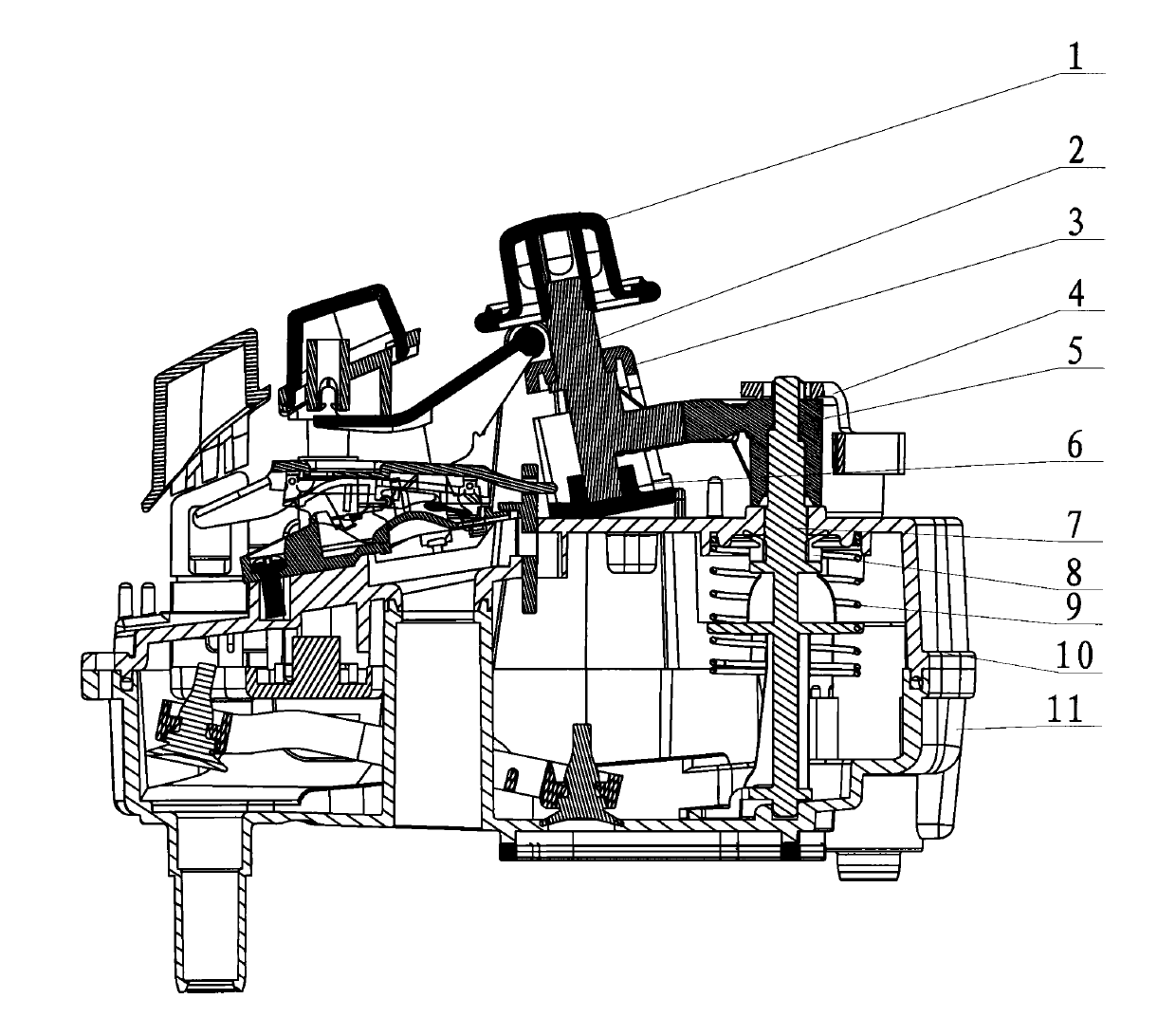

[0017] The structure diagram of the present invention is as figure 1 , 2 As shown, the water output adjustment mechanism of the instant electric kettle of the present invention includes a water adjustment knob 1, a driving gear 2, a driven gear 5, a water adjustment rod 7, a steam box cover 10, and a steam box 11, wherein the driving gear 2 The rotating shaft is connected to the water adjustment knob 1, the driven gear 5 is meshed with the driving gear 2, and the driven gear 5 is fixed on the bottom of the steam box 11 through the control structure to control the exposed size of the drain hole on the steam box 11 to control the displacement. On the water adjustment lever 7.

[0018] The fixed block 4 that can press the driven gear 5 and prevent the driven gear 5 from moving is fixed on the above-mentioned steam box cover 10 . In this embodiment, the above-mentioned fixing block 4 is fixed on the steam box cover 10 by screws.

[0019] In order to ensure the tightness and pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com