Positioning and resetting structure of hand-operated direction valve

A manual reversing valve, reset structure technology, applied in the valve operation/release device, valve details, multi-way valve and other directions, can solve the problem of unable to spool, return to the original position, unable to automatically reset, etc., to achieve convenient operation , the effect of good operating feel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

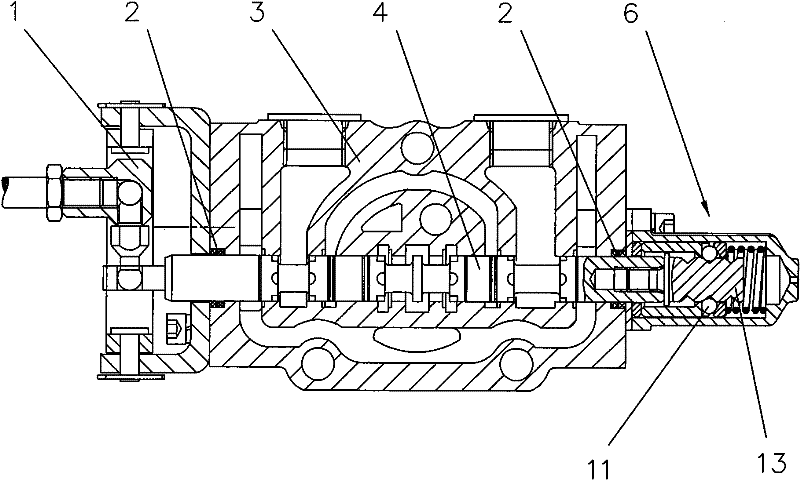

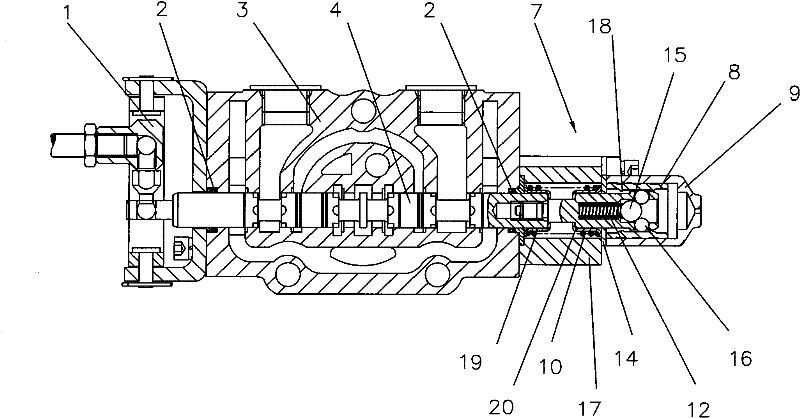

[0023] see figure 2 , image 3 , Figure 4 , Figure 5 , the positioning and reset structure of the manual reversing valve, the manual reversing valve includes a manual reversing mechanism 1, a valve body 3, a valve core 4, a rear end cover 17, a rear cover 9 and a positioning and resetting mechanism 7, and the left end of the valve core 4 is connected to There is a manual reversing mechanism 1, which is characterized in that the right end of the valve core 4 is set as a positioning reset mechanism 7; the positioning reset mechanism 7 is located in the cavity formed by the rear end cover 17 and the rear cover 9 arranged in sequence from left to right Inside; the positioning reset mechanism 7 includes back-moving spring 10, spring seat, positioning spring 12, pressure pad 14, positioning ball group and positioning sleeve 8; spring seat includes left spring seat 19 and right spring seat 20, left spring seat 19 and The right spring seat 20 is all sleeved on the spool 4 and ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com