Mini-fan performance test system based on human-computer interaction interface

A human-computer interaction, micro-fan technology, applied in pump testing, machine/engine, mechanical equipment, etc., can solve the problem of inability to test the performance of micro-fans

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

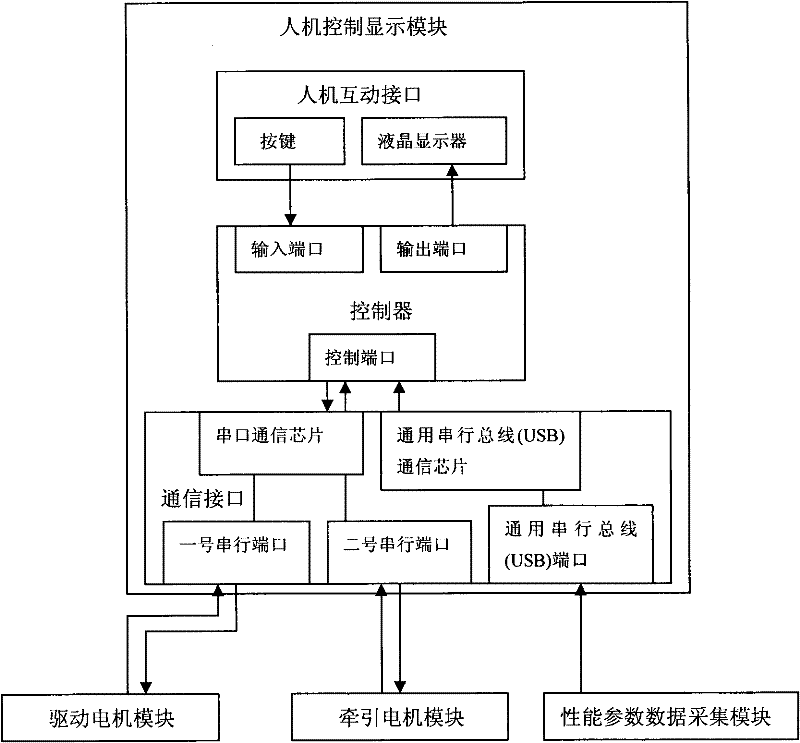

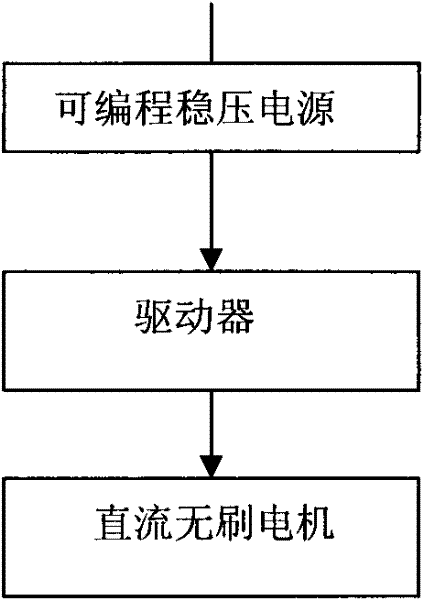

[0016] The present invention adopts the human-machine control display module based on the human-computer interaction interface, which can not only accept the user's instructions, but also provide the measured data and performance curves required by the user; it can not only send instructions to the drive motor module and the traction motor module, but also Real-time measured data such as differential pressure, static pressure, torque, rotational speed, and wind speed can be obtained from the performance parameter data acquisition module.

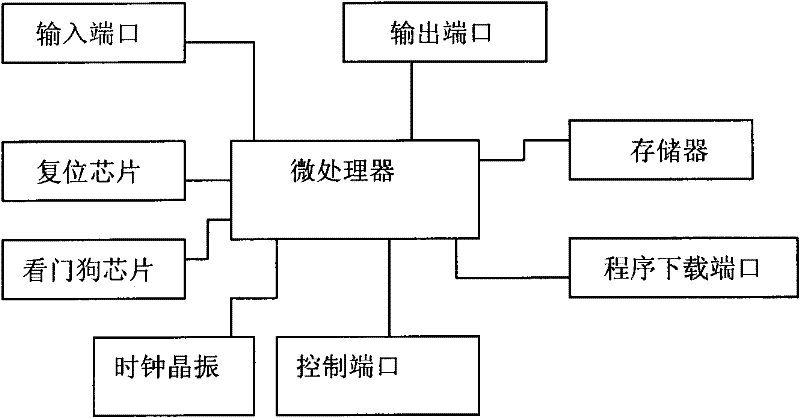

[0017] like figure 1 As shown, the micro-fan performance test system based on human-computer interaction interface has a man-machine control display module, which is respectively connected with the drive motor module, performance parameter data acquisition module, and traction motor module. The human-computer interaction interface is composed of buttons and liquid crystal displays. The buttons of the human-computer interaction interface are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com