Steel plate width control method

A width control and width technology, applied in the direction of metal rolling stand, metal rolling mill stand, etc., can solve the problems that the mathematical model of rough rolling is difficult to adapt to the requirements of equipment and production process, the capacity of equipment cannot be fully utilized, and waste of resources and other problems , to achieve the effect of reasonable steel plate width control parameters, eliminating plate width oscillation phenomenon, and improving the qualified rate of width accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] In the non-pressure sizing machine, the large vertical roll for rough rolling undertakes the main task of side pressure; the vertical roll mill for rough rolling cross-rolls strips of different widths.

[0024] Incoming slab specification: 135×1275mm; Finished steel strip specification: 2.95×1262mm; 2.95×1235mm;

[0025] The lateral pressure X is respectively: 13mm, 40mm;

[0026] The first rolling mill for rough rolling is a reversible rough rolling mill, which adopts 3-pass reversible rolling.

[0027] 1. Use the original rough rolling mathematical model width calculation formula, namely:

[0028] W OUT =W'+Lcw Lay ·{Aw Lay (j)·S ES +Aw Lay (l) ΔH+Aw Lay (k)·W′·ΔH}

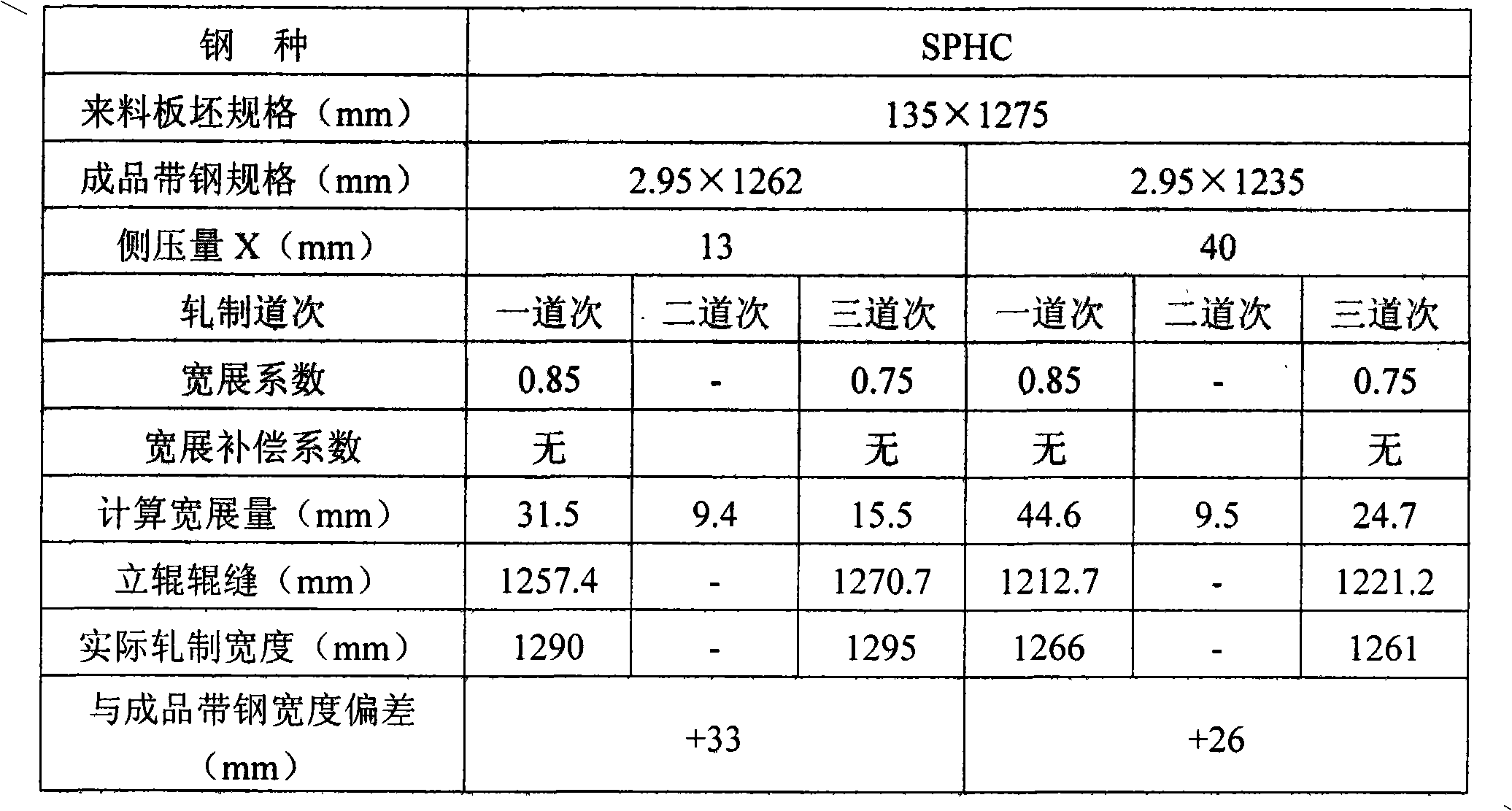

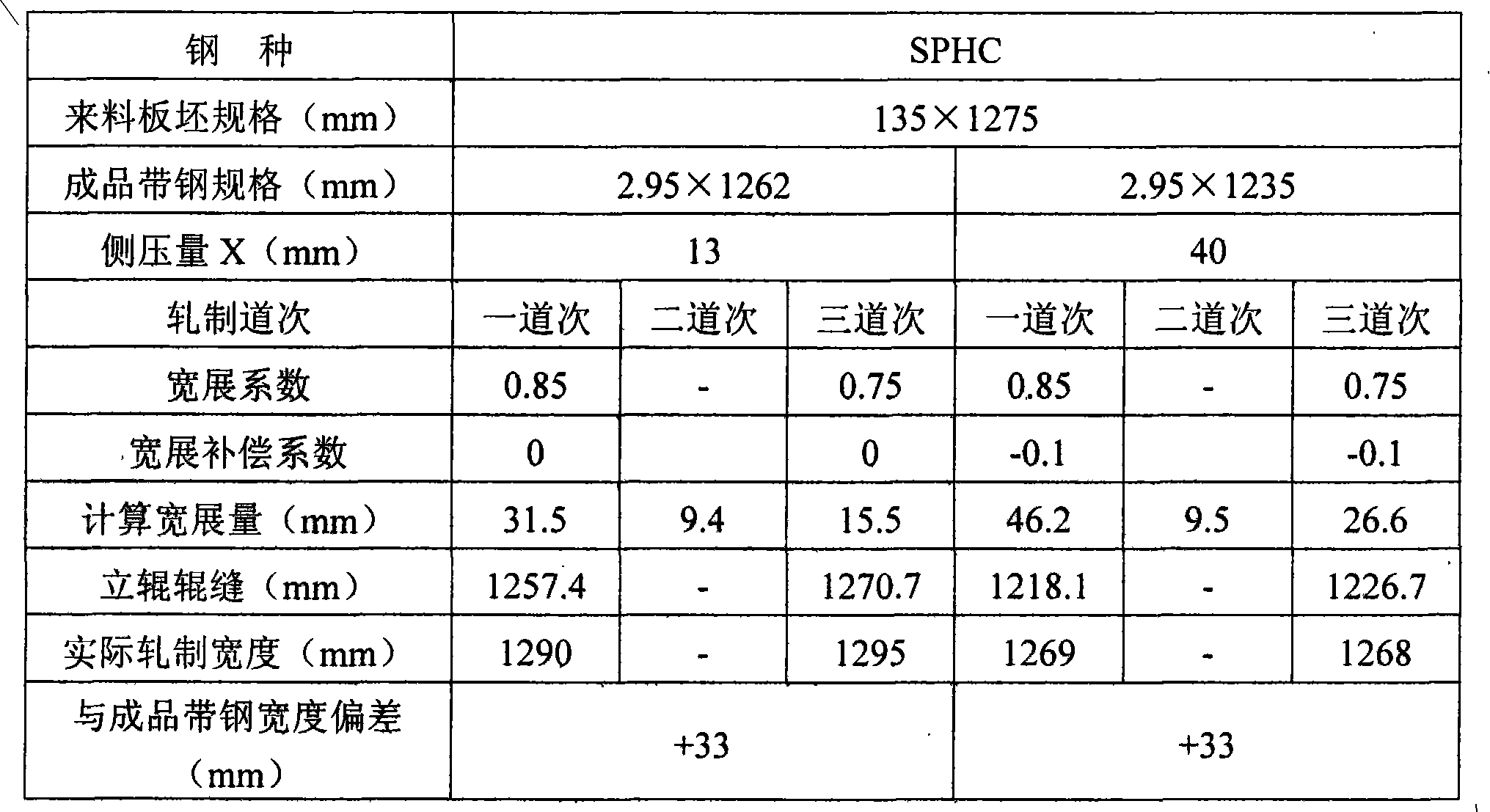

[0029] The spread coefficient of the first pass of rough rolling is 0.85, and the spread coefficient of the mathematical model is reduced by 0.1 every time the slab is rolled back and forth. The actual rolling data is as follows:

[0030]

[0031] It can be seen from the above table that the ...

Embodiment 2

[0039] Rough rolling non-pressure sizing machine, the rough rolling large vertical roll undertakes the main side pressure task; the rough rolling vertical roll mill cross-rolls strips of different widths.

[0040] Incoming slab specification: 135×1275mm; Finished steel strip specification: 3.05×1250mm; 3.05×1210mm;

[0041] The lateral pressure X is respectively: 25mm, 65mm;

[0042] The first rolling mill for rough rolling is a reversible rough rolling mill, which adopts 3-pass reversible rolling.

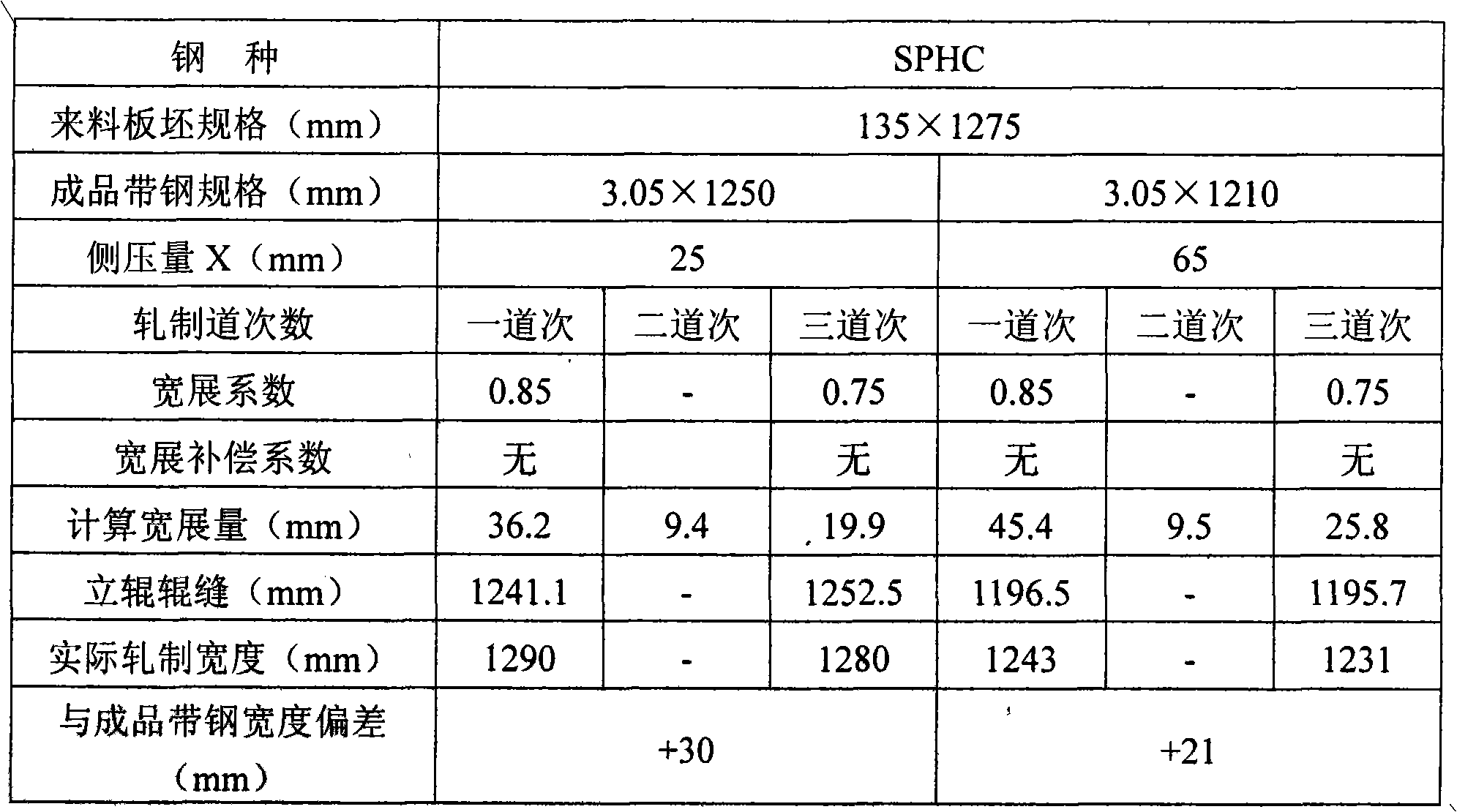

[0043] 1. Using the calculation formula of the original mathematical model of rough rolling, the spread coefficient of the first pass of rough rolling is 0.85, and the spread coefficient of the mathematical model is reduced by 0.1 every time the slab is rolled back and forth. The actual rolling data is as follows:

[0044]

[0045] It can be seen that the deviation between the actual width of the rolled strip and the width of the finished strip is +30mm and +21mm respectively...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com