Remote fault diagnosis method for digging machine

A remote diagnosis and fault technology, applied in the fields of earth movers/shovels, electrical components, transmission systems, etc., can solve the problems of complicated inspection process operation, decline of product social reputation, etc., to reduce trouble, improve maintenance efficiency, The effect of reducing the use and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

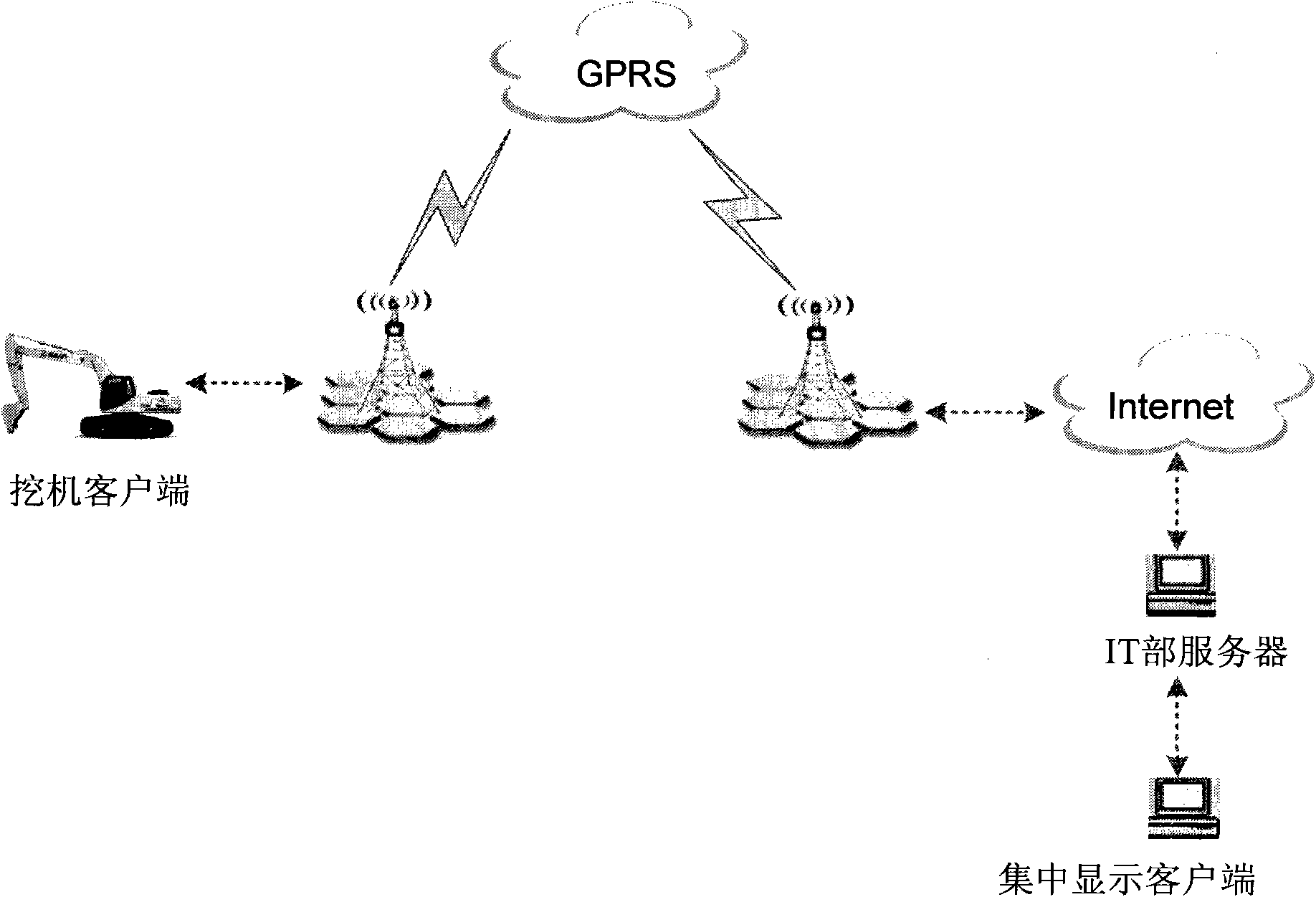

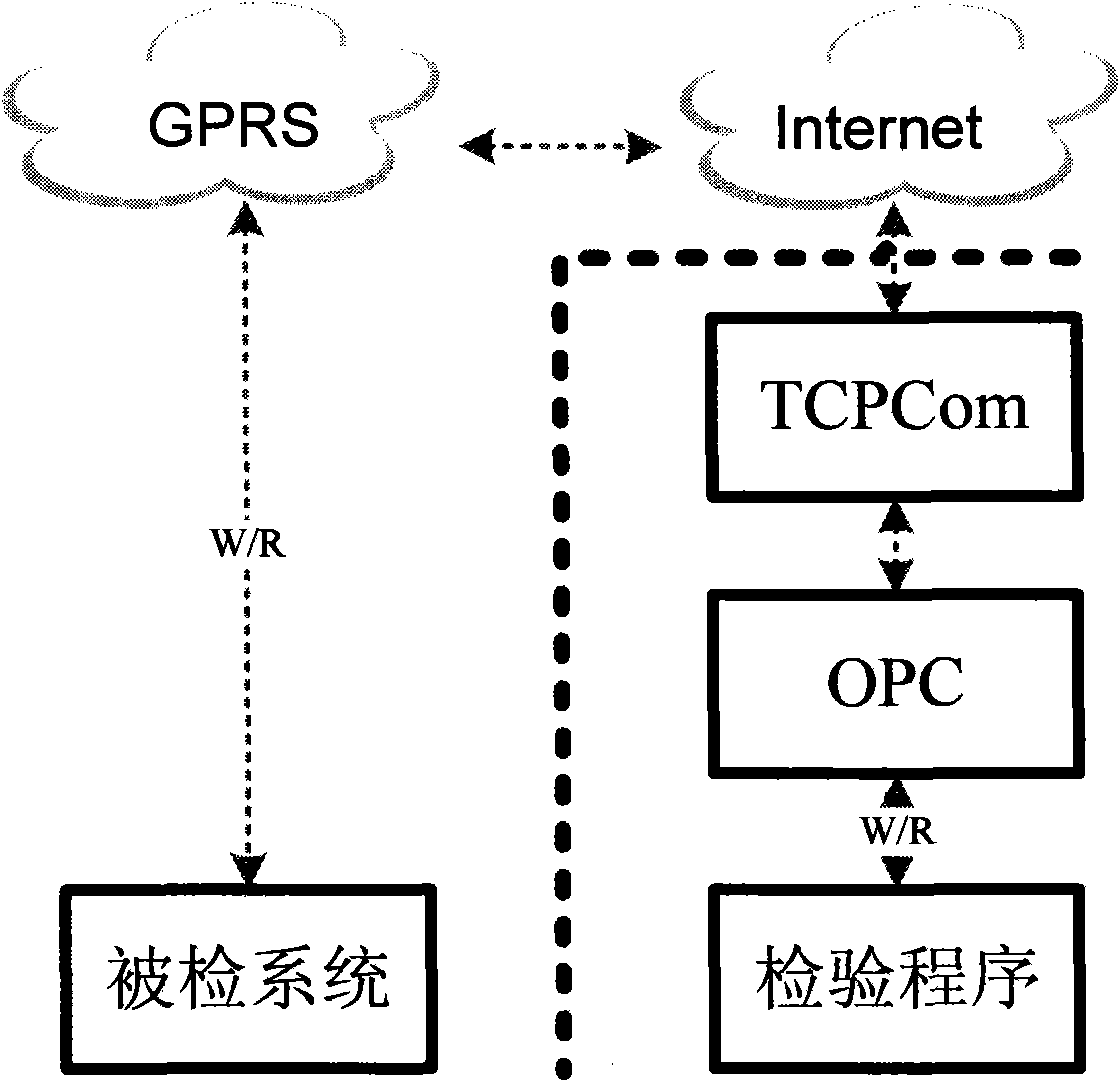

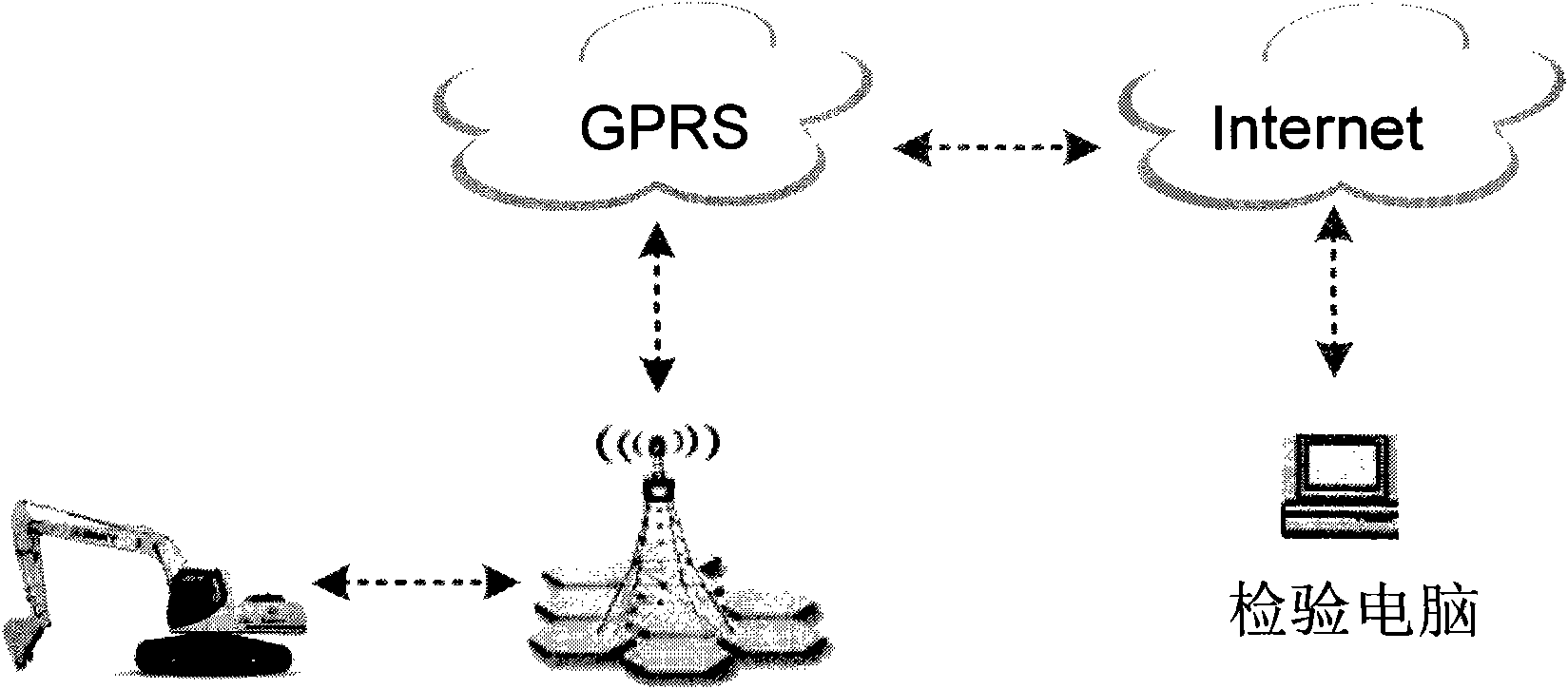

[0028] Embodiment one: see figure 2 , 3 Shown, a kind of excavator remote diagnosis fault method, it comprises the following steps:

[0029] (1) Initialize the configuration of relevant parameters for the OPC module and the TCP-COM conversion module, including: port number, IP address, baud rate, parity bit and other related information;

[0030] (2) Establish a connection between the TCP-COM conversion module and the excavator to be tested through the GPRS wireless network and the Internet network;

[0031] (3) The inspection computer sends an access request to the connected excavator through the OPC module;

[0032] (4) The excavator to be tested (system under test) outputs each corresponding diagnostic parameter according to the access request;

[0033] (5) The inspection computer judges the acquired diagnostic parameters according to the built-in inspection program, outputs the inspection results, displays them on the inspection computer interface, and generates a repo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com