Wig, and its manufacturing method

A wig and hair technology, applied in the field of manufacturing the wig, can solve the problem of insufficient erection of hair, and achieve the effects of preventing hair loss, simplifying the manufacturing process, and preventing loosening of knots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] (Example 1)

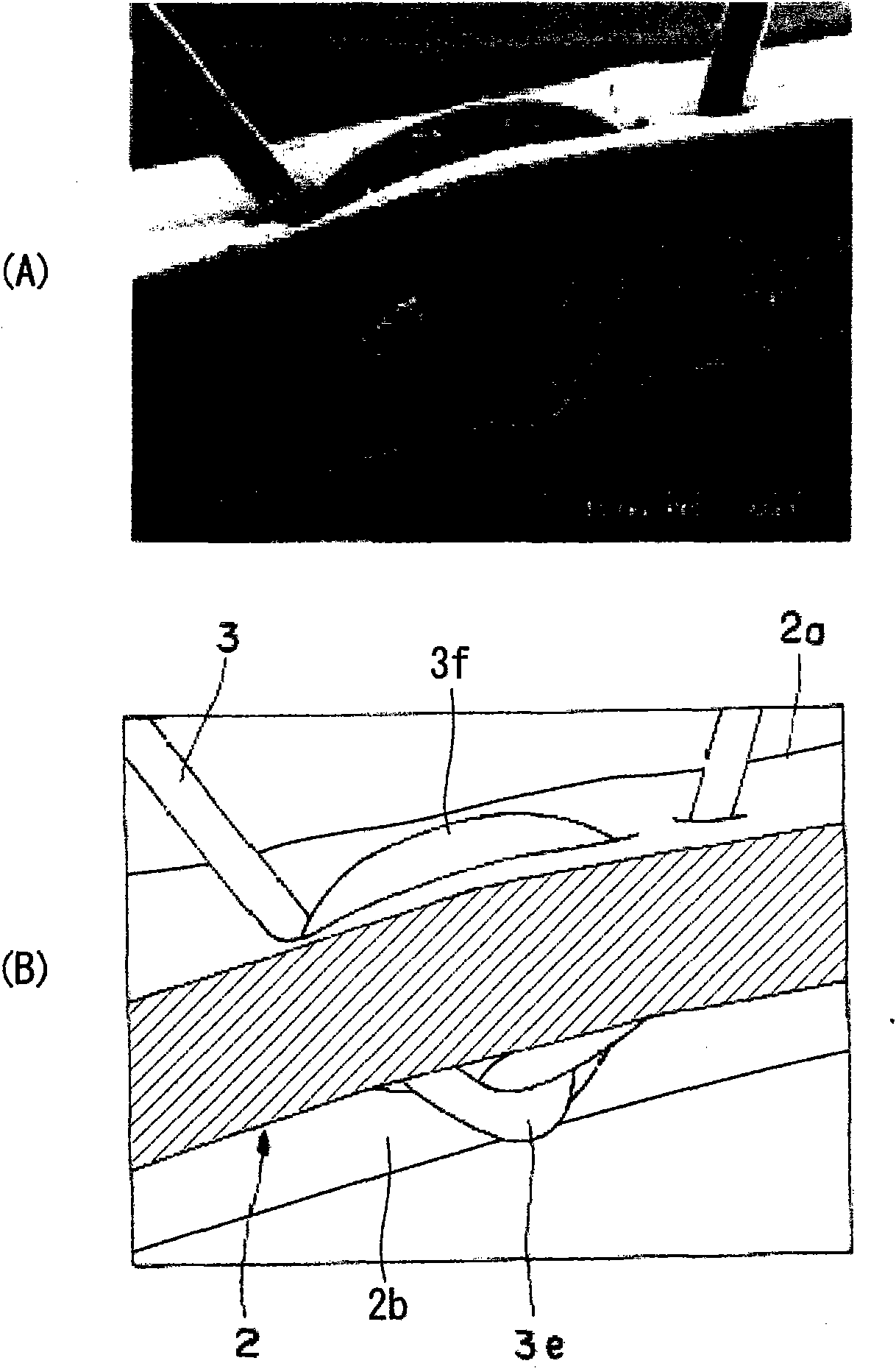

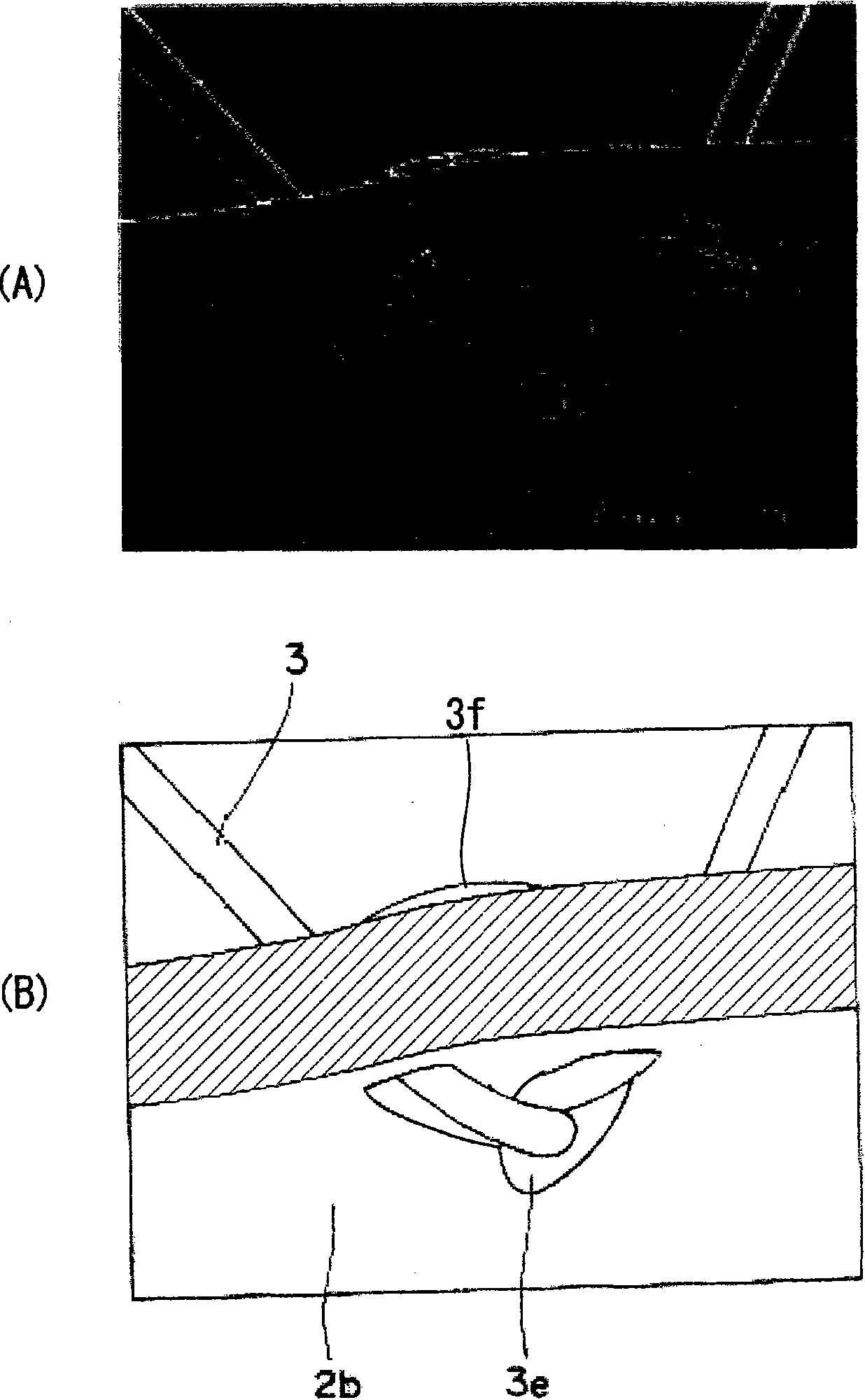

[0066] A wig as Example 1 was produced by the method described above as an example. A 0.2mm thick soft artificial skin made of polyurethane resin was used as a wig base, and a large number of artificial hairs made of polyamide resin with a diameter of 0.08mm were implanted. figure 2 , image 3 and Figure 4 It is a cross-sectional view showing the implanted hair of the wig viewed from above at an oblique angle, from below at an oblique angle, and from the bottom. figure 2 of (A), image 3 (A) and Figure 4 (A) are scanning electron micrographs taken at magnifications of 90x, 80x, and 80x, respectively. figure 2 of (B), image 3 (B) and Figure 4 (B) is a diagram illustrating these components. As can be clearly seen from these figures, the knot 3e of the wig of the embodiment is located on the back 2b of the wig base 2, and the loop 3f connected to the knot 3e is located on the front 2a.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com