Auxiliary support for centering tool

A technology of auxiliary brackets and tools, applied to supporting machines, measuring devices, instruments, etc., can solve the problems of difficulty in accurate measurement, labor intensity of workers, low work efficiency, etc., and achieve the effect of easy implementation, simple structure and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

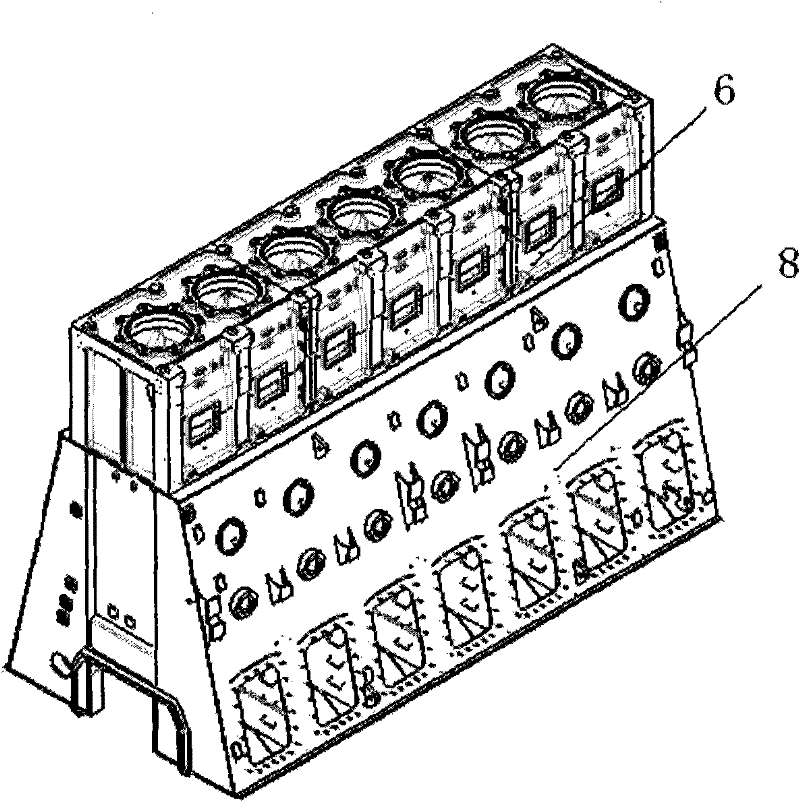

Image

Examples

Embodiment Construction

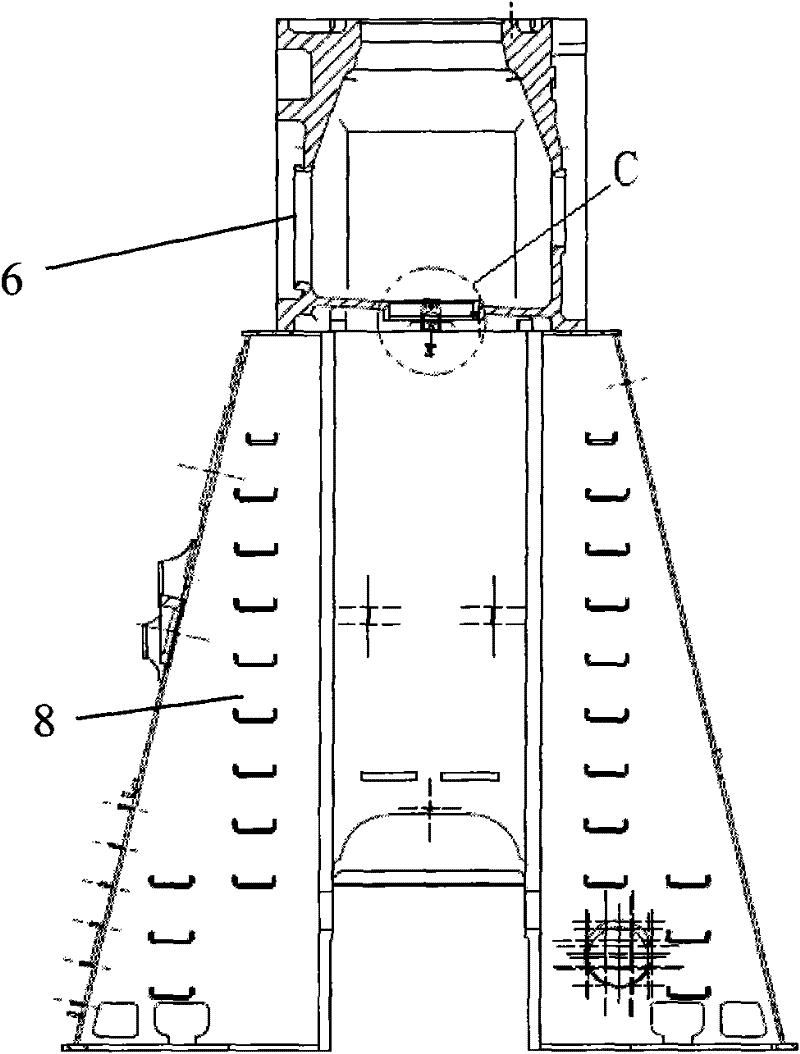

[0018] see figure 2 In this embodiment, the horizontal hanging board 1 and the vertical positioning board 2 constitute an inverted "L"-shaped bracket, and the upright measuring rod 4 for installing the rangefinder 3 is fixedly connected to the bottom of the vertical positioning board 2; On the vertical positioning plate 2, three longitudinal positioning long holes 5 are distributed in the shape of a product, and positioning bolts 7 are respectively arranged in each positioning long hole 5. The positioning height of the positioning bolts 7 in each positioning long hole can be adjusted, and the positioning The protruding length of the bolt passing through each positioning slot 5 can be adjusted.

[0019] Such as figure 2 , Figure 3a with Figure 3b As shown, in use, the rangefinder 3 used for centering and alignment is fixedly installed on the upright measuring rod 4 of the auxiliary bracket, and the height and angle of the rangefinder 3 on the upright measuring rod 4 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com