Vibration drawbench

A vibrator and vibration frequency technology, which is applied in the field of pullers, can solve problems such as difficult to disassemble the fastening parts on the shaft, and achieve the effects of improving working capacity, reducing friction, and reducing equipment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

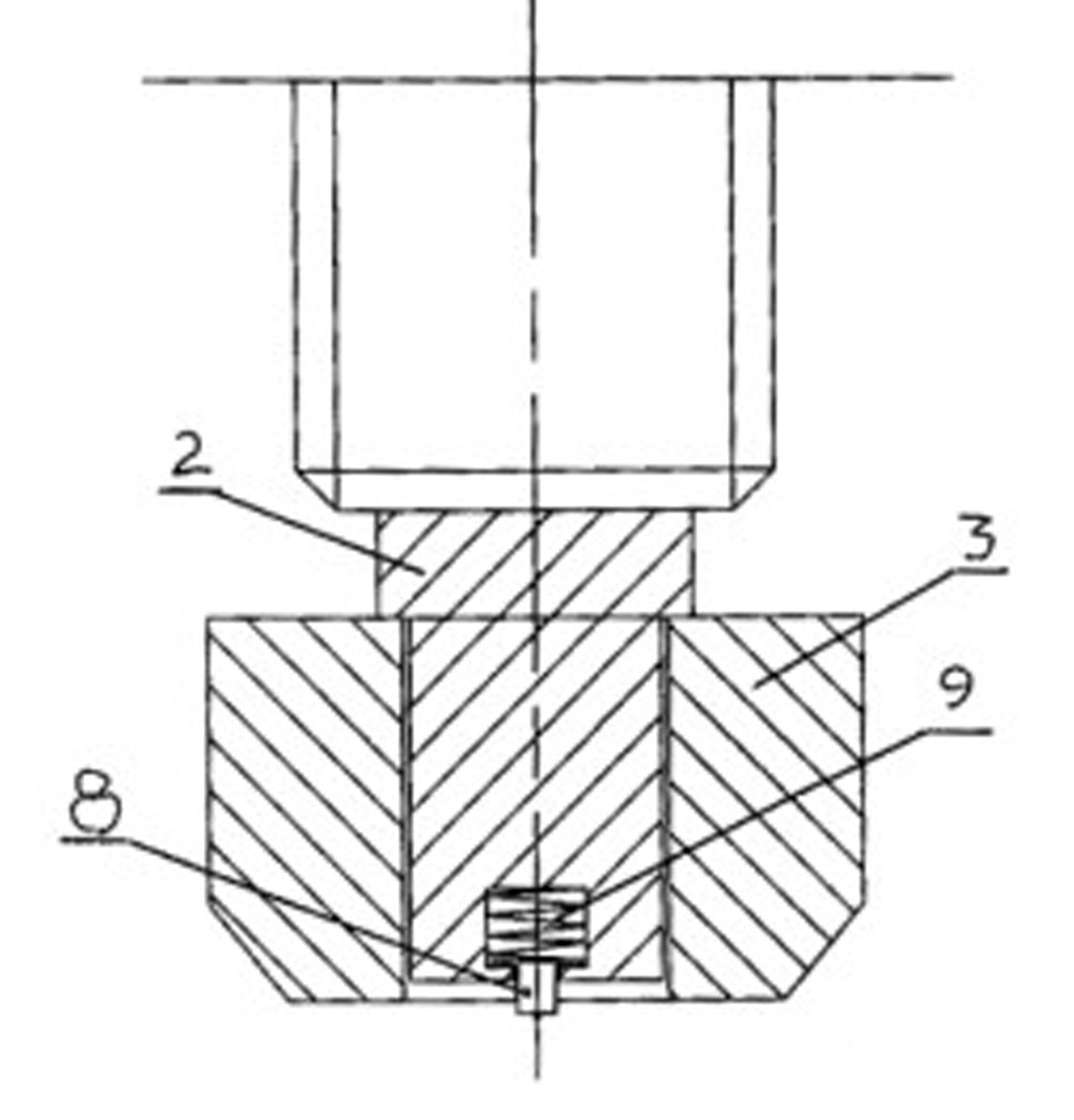

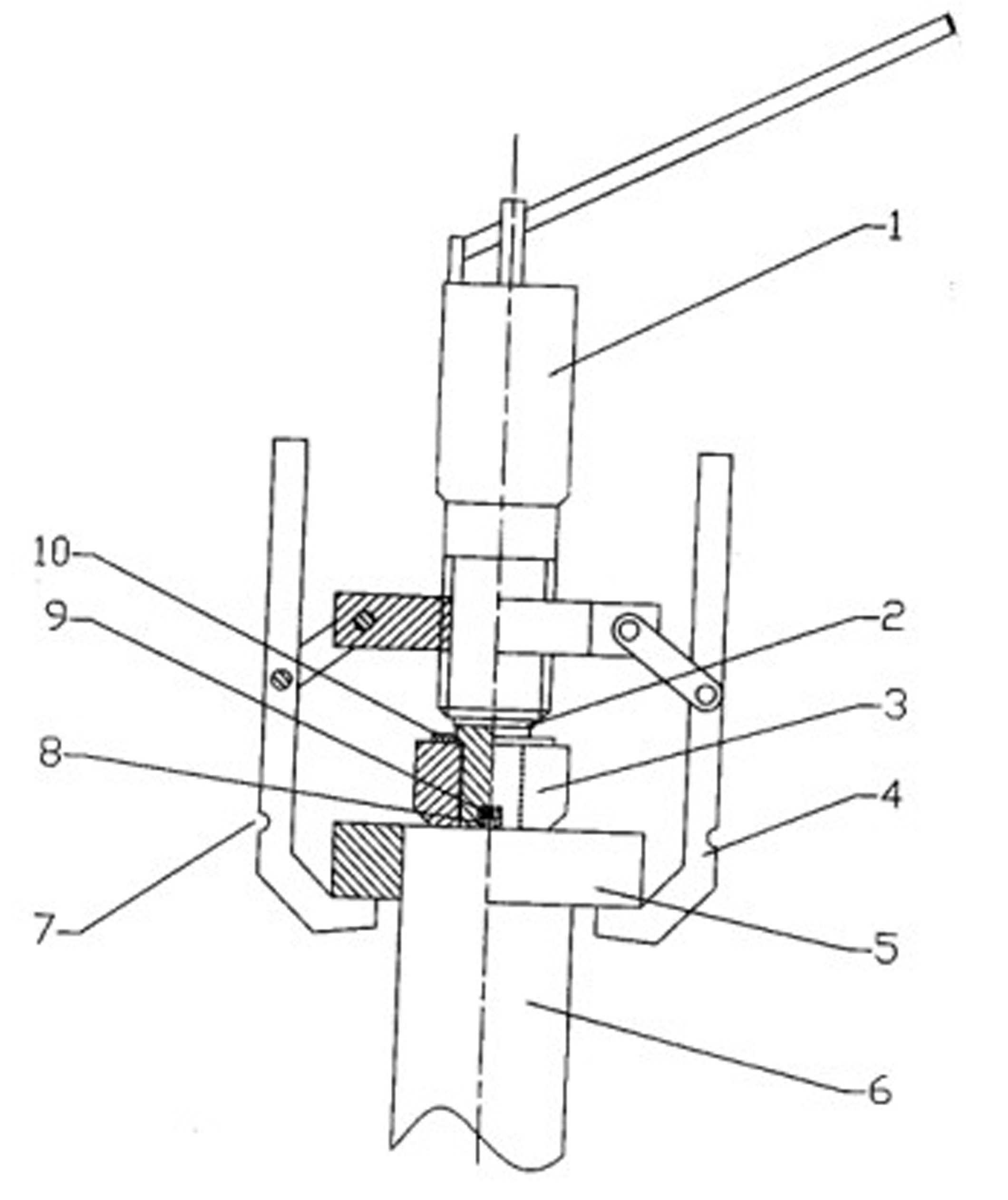

[0013] like image 3 , 4 As shown, the vibrating puller includes a push rod 2 and a claw 4 connected to the push rod 2 , and a vibrator 3 with adjustable vibration frequency is installed at the end of the push rod 2 . In this specific embodiment, the push rod 2 is in the form of a jack 1 .

[0014] The vibrator 3 with adjustable vibration frequency adopts existing products, and the vibrator 3 with adjustable vibration frequency is made into a ring shape. On the tapering part of the end of the ejector rod 2, a preloading ring 10 threaded with the non-reducing part of the ejector rod is sleeved on the ejector rod 2. When in use, the preloading ring is screwed down to make the puller ejector rod pass through There is a proper pre-tightening force between the pre-tightening ring and the vibrator, so that the vibrator and the ejector rod become a whole that can vibrate and generate resonance at the same time, and transmit the vibration and resonance to the disassembled part 5 thr...

Embodiment 2

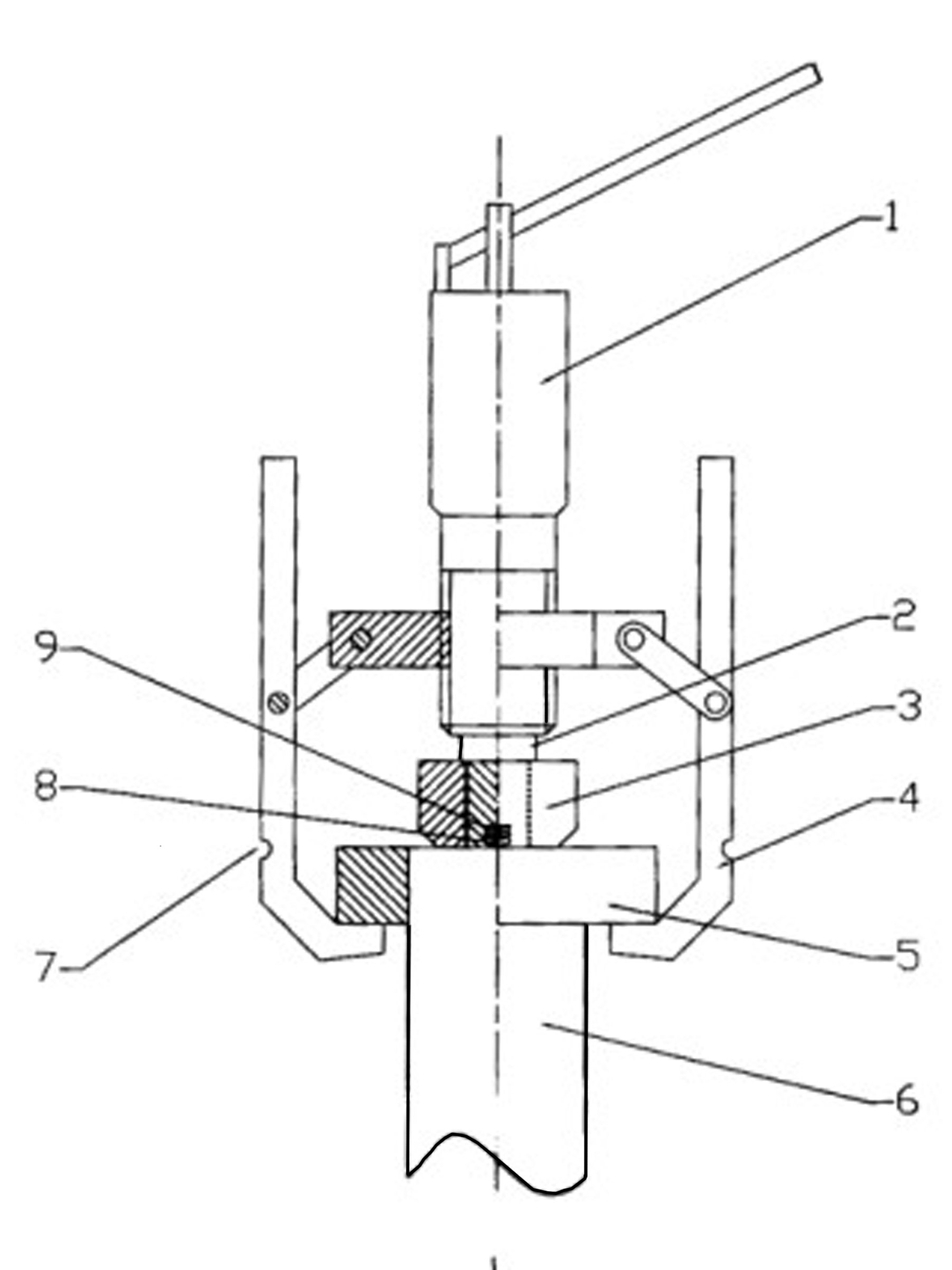

[0019] like figure 1 , 2 As shown, the vibrating puller includes a push rod 2 and a claw 4 connected to the push rod 2 , and a vibrator 3 with adjustable vibration frequency is installed at the end of the push rod 2 . In this specific embodiment, the push rod 2 is in the form of a jack 1 .

[0020] The vibrator 3 with adjustable vibration frequency adopts existing products, and the vibrator 3 with adjustable vibration frequency is made into a ring shape. On the tapered portion at the end of the ejector rod 2, the length of the tapered portion of the ejector rod is less than the thickness of the annular vibrator and the difference between the thickness of the annular vibrator and the length of the tapered portion of the ejector rod is smaller than the elastic deformation size of the vibrator, During specific implementation, the difference between the thickness of the ring vibrator and the length of the tapered part of the ejector rod (the length of the tapered part of the eje...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com