Mn-Ni-SBA-15 coating material for removing ozone

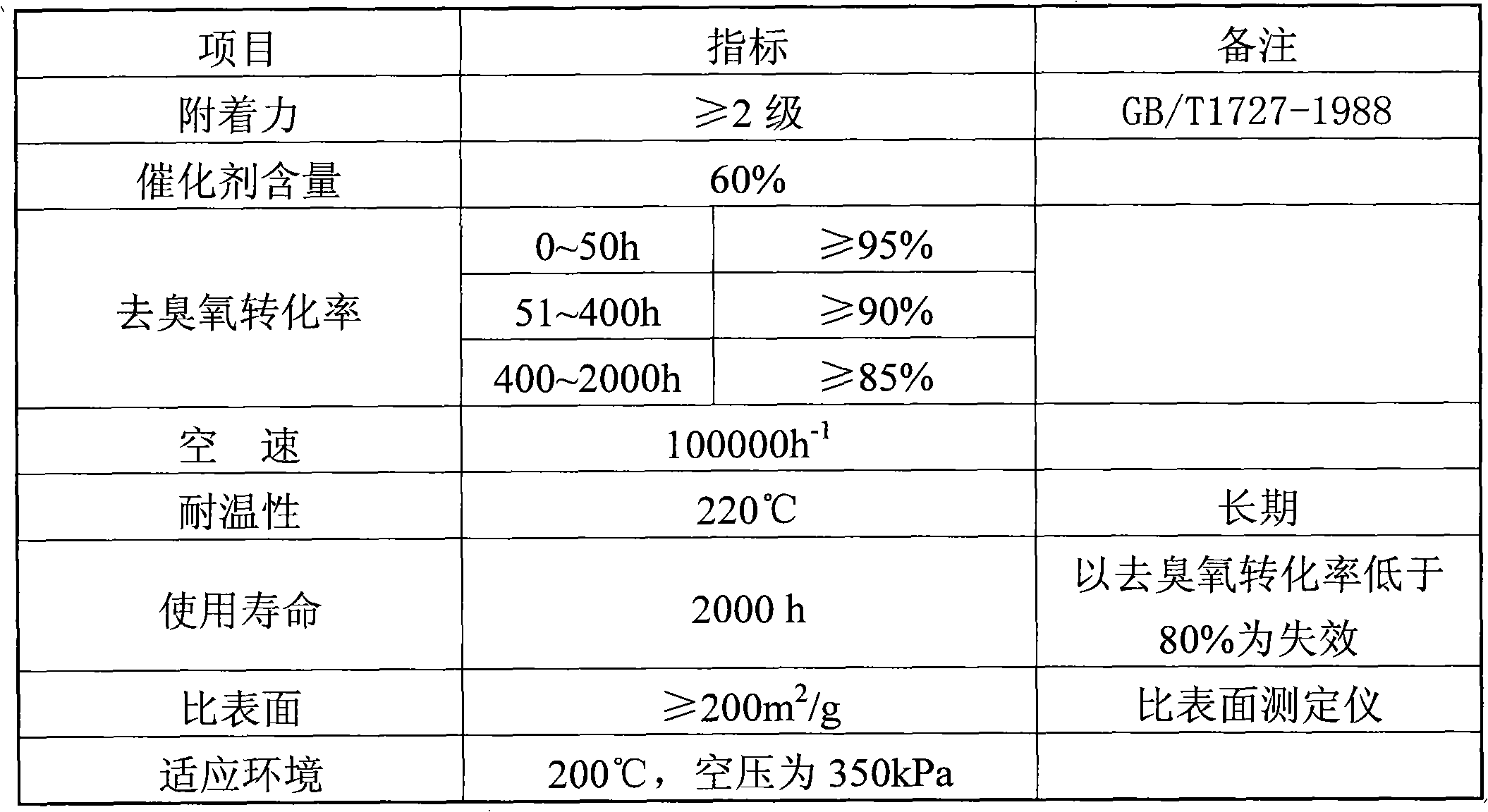

A coating material and ozone technology, applied in the direction of coating, etc., can solve the problems of ozone sterilizer environmental hazards and other problems, and achieve the effect of good adhesion and efficient service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] Preparation of Mn-Ni-SBA-15: 1.0Kg triblock surfactant P123 (Aldrich, EO 20 PO 70 EO 20 , M=5800) was dissolved in 22Kg deionized water. Then 15Kg of 4mol / L HCl solution was added, and 2.1Kg of tetraethyl orthosilicate was added under stirring, and kept stirring vigorously for 22h. The mixed solution was transferred to polytetrafluoroethylene In the bottle, crystallize at 100°C for 24 hours, then filter, wash, and dry, and finally roast the dried product at 550°C for 6 hours to remove the template agent, and obtain SBA-15 mesoporous molecular sieve white powder. Dilute 1.0Kg nitric acid Dissolve manganese and 0.1Kg nickel nitrate in 1.0Kg deionized water, add SBA-15 mesoporous molecular sieve, impregnate overnight, dry at 110°C for 12h, then roast in air at 550°C for 5h, and cool naturally to room temperature to obtain Mn-Ni -SBA-15 catalyst.

[0030] Active filler γ-Al 2 o 3 Preparation: Weigh 500g of aluminum hydroxide (CP. grade), put it in a ceramic pot, put it...

Embodiment 1

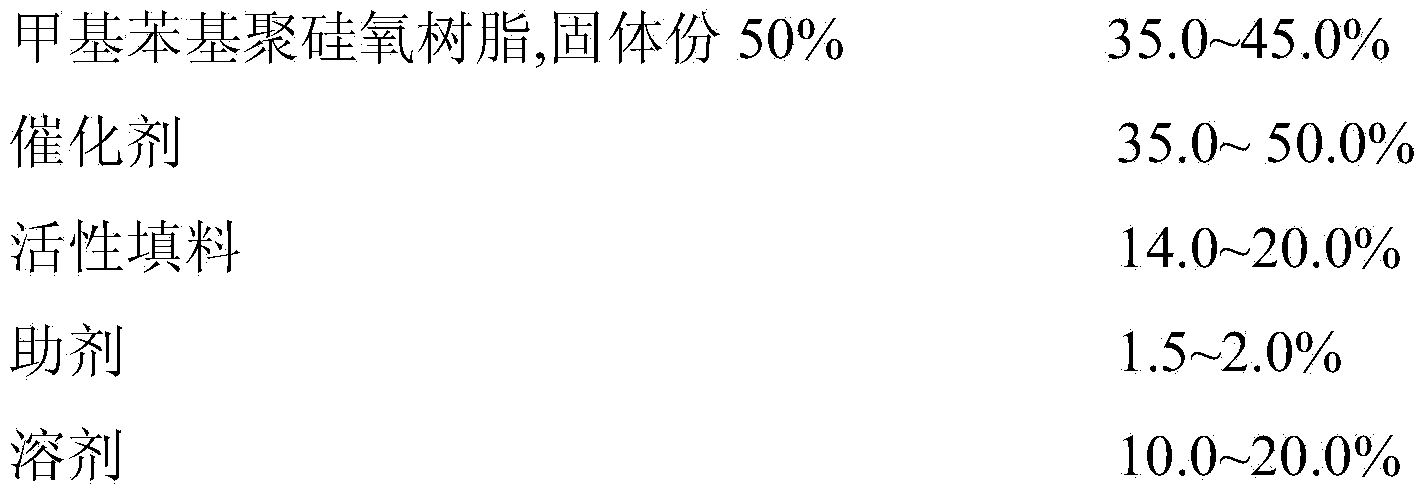

[0032] Coating Formulation:

[0033] 50% silicone resin (1053) 30.0g

[0034] Mn-Ni-SBA-15 22.0g

[0035] γ-Al 2 o 3 8.0g

[0036] KH-550 0.5g

[0037] Xylene 10.0g

[0038] Preparation Process:

[0039] (1) Weighing and pre-mixing: Accurately weigh 50% silicone resin, Mn-Ni-SBA-15, γ-Al according to the formula 2 o 3 , KH-550 and xylene, put into the mixing tank, stir evenly to form a mixture;

[0040] (2) Grinding and dispersing: Grind and disperse the mixture with a conical mill, control the fineness to below 45 μm with a scraper fineness meter, and filter out the material.

[0041] (3) Coated board: Spray the paint on the anodized bottom board with a thickness of 150 μm or less.

[0042] (4) Coating treatment: After drying the coating at room temperature for 8 hours, bake it in an oven at 120°C for 2 hours, then bake it at 150°C for 1 hour; put it in a muffle furnace for 4 hours, then cool it to 100 Take it out below ℃, that is, the coated pr...

Embodiment 2

[0044] Coating Formulation:

[0045] 50% silicone resin (1053) 35.0g

[0046]Mn-Ni-SBA-15 20.0g

[0047] γ-Al 2 o 3 10.0g

[0048] KH-550 0.8g

[0049] Xylene 13.0g

[0050] Preparation Process:

[0051] (1) Weighing and pre-mixing: Accurately weigh 50% silicone resin, Mn-Ni-SBA-15, γ-Al according to the formula 2 o 3 , KH-550 and xylene, put into the mixing tank, stir evenly to form a mixture;

[0052] (2) Grinding and dispersing: Grind and disperse the mixture with a conical mill, control the fineness to below 45 μm with a scraper fineness meter, and filter out the material.

[0053] (3) Coated board: Spray the paint on the anodized bottom board with a thickness of 150 μm or less.

[0054] (4) Coating treatment: After the coating is dried at room temperature for 8 hours, it is baked in an oven at 120°C for 1 hour, and at 150°C for 1.5 hours; after it is baked in a muffle furnace at 350°C for 6 hours, it is cooled to 100°C with the furnace. Take it ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com