Stacking device for printed products

A stacking device, stacking technology, applied in stack receiving device, transportation and packaging, function indication, etc., can solve the problems of high load, prolonged cycle time, etc., and achieve reliable control, precise control, and rapid direction change. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

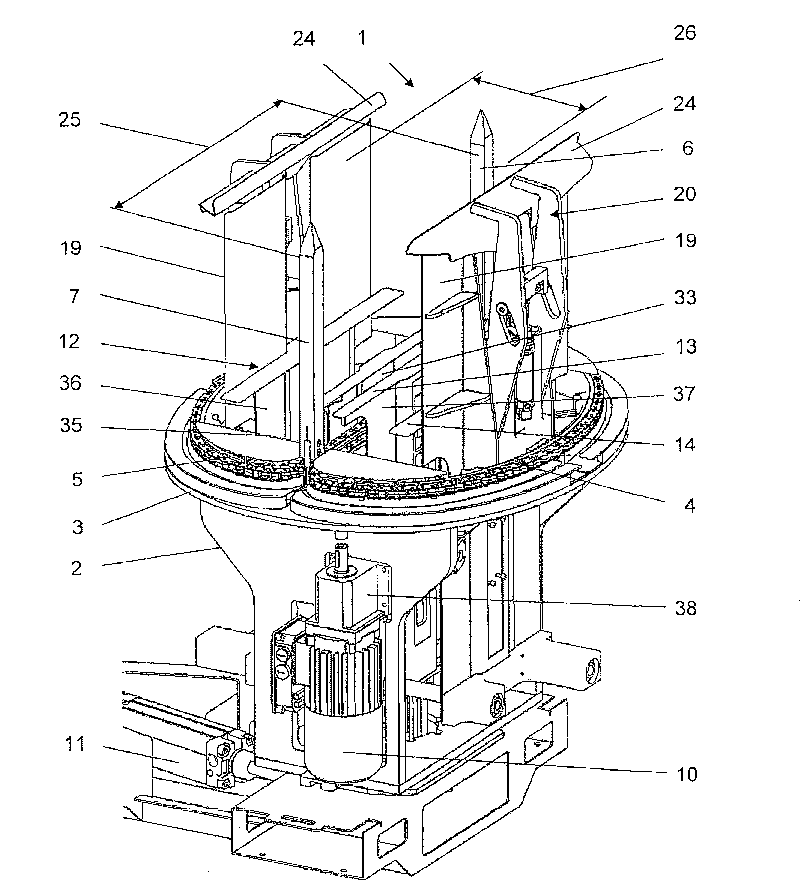

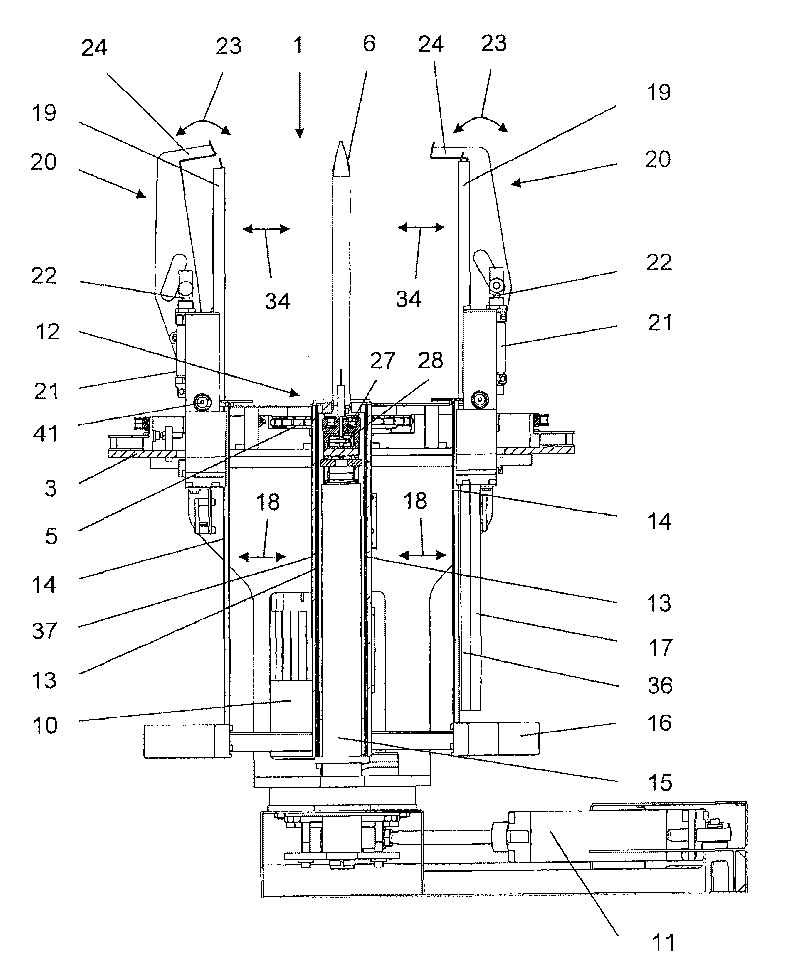

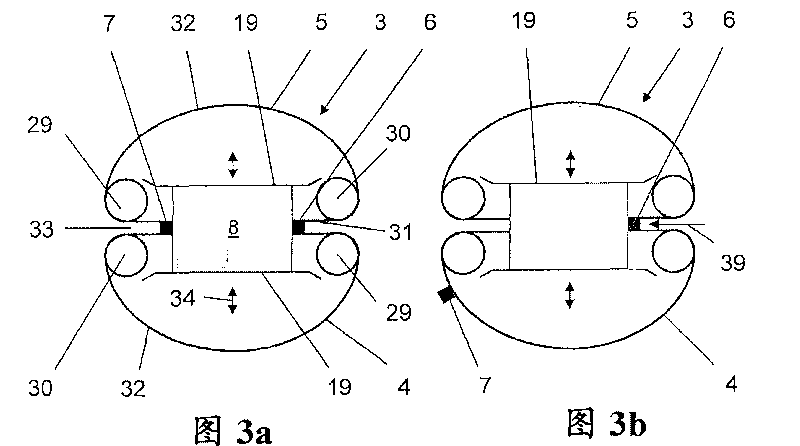

[0023] exist figure 1 with figure 2 The stacking device 1 shown in has a frame 2 with an approximately horizontal table 3 on which two endless drives 4 , 5 are supported. Arranged in the recess 35 of the table 3 is a lift 12 with two inner lift plates 13 and two outer lift plates 14 . Can be formed on this lift 12 Figure 3a to Figure 3d A stack 8 of printed products 9 is shown schematically in , wherein a lift 12 makes it possible to reduce the fall height of the printed products 9 . The stack 8 can consist of layers of printed products 9 which are each rotated by 180° relative to each other. For stacking, the table 3 can be rotated about a vertical axis by means of a servo cylinder 11 . This is known as so-called cross placement and is well known to those skilled in the art.

[0024] The stack 8 formed in this way can be squeezed, ie compacted, by raising the lift 12 against the press flap 20 . exist figure 2 Shown are two pressure flaps 20 arranged pivotably inward...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com