Optimal position calibration method of static drifting zero and primary acceleration related term error model of flexible gyroscope

A technology of flexible gyroscope and static drift, which is applied in the direction of speed measurement by gyro effect, gyroscope/steering sensing equipment, speed/acceleration/shock measurement, etc. Significantly improved, high test costs and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

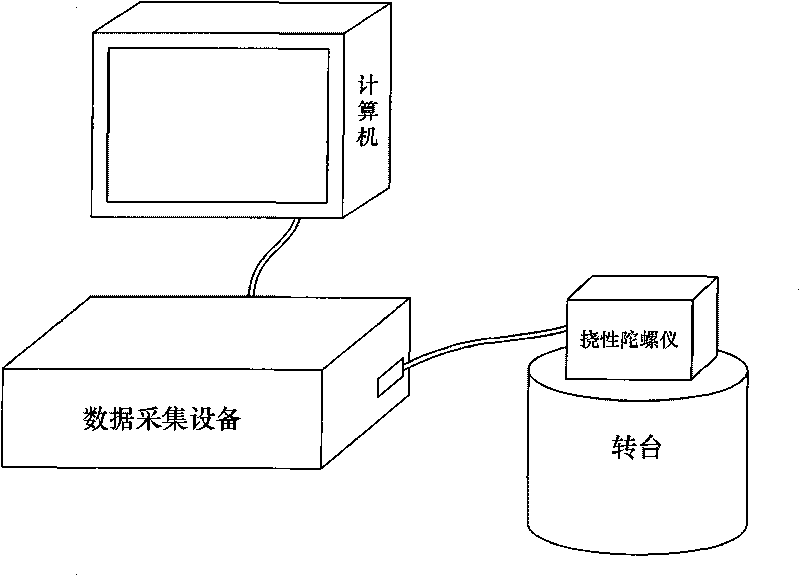

Method used

Image

Examples

example 1

[0130] Comparative example 1: traditional eight-position test method

[0131] Carry out the traditional eight-position test according to the traditional eight-position test method stipulated in IEEE Std 813-1988 or the national military standard. The test method and steps are the same as the above-mentioned spatial orthogonal twelve-position test method, except that the test orientation is changed as shown in Table 3 The traditional eight positions of the collected position-data are shown in the X-axis data and Y-axis data in Table 3 after removing wild points.

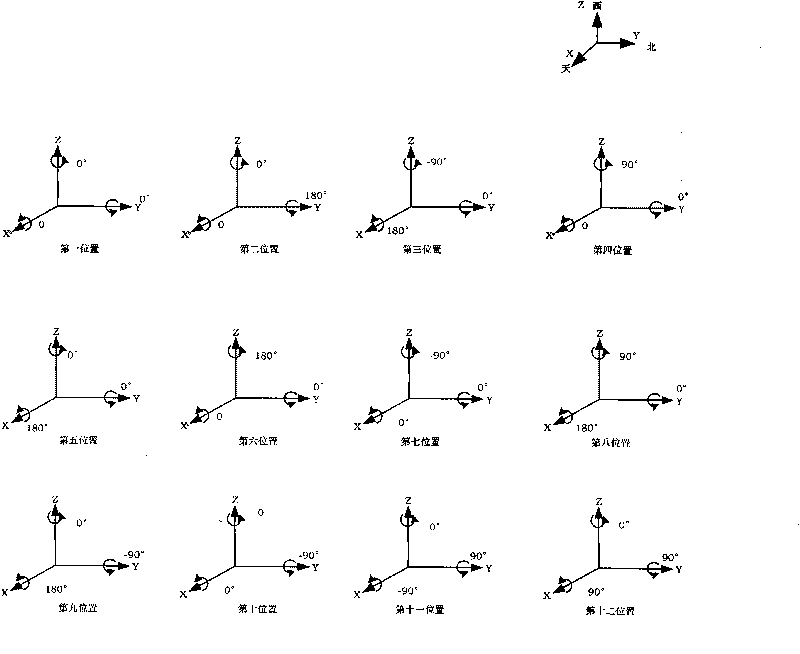

[0132] see Figure 4 As shown, the traditional eight positions are expressed in the following table:

[0133] first position

[0134] Note: θ is the rotation angle of the X axis, γ is the rotation angle of the Y axis, and φ is the rotation angle of the Z axis.

[0135] Table 3 Experimental data of two measuring axes under traditional eight positions

[0136] position

[0137] position ...

example 2

[0138] Comparative example 2: full-space orthogonal twenty-four-position test method

[0139] Carry out the test according to the full-space orthogonal twenty-four positions shown in Table 4. The test method and steps are still the same as the above-mentioned space orthogonal twelve-position test method, but the test orientation is changed to the full space orthogonal as shown in Table 4. Position, the collected position-data after removing wild points is shown in the X-axis data and Y-axis data in Table 4.

[0140] see Figure 5 As shown, the full-space orthogonal twenty-four positions are expressed in the following table:

[0141] first position

[0142] first position

[0143] Note: θ is the rotation angle of the X axis, γ is the rotation angle of the Y axis, and φ is the rotation angle of the Z axis.

[0144] Table 4. Experimental data of two measurement axes in full-space orthogonal twenty-four positions

[0145] position

[0146] ...

Embodiment

[0148] Please refer to Table 7. It can be seen that the accuracy of the space-orthogonal twelve-position test method is greatly improved compared with the traditional eight-position test method, and the accuracy of the full-space orthogonal twenty-four-position test method is improved and the test time is shortened by half.

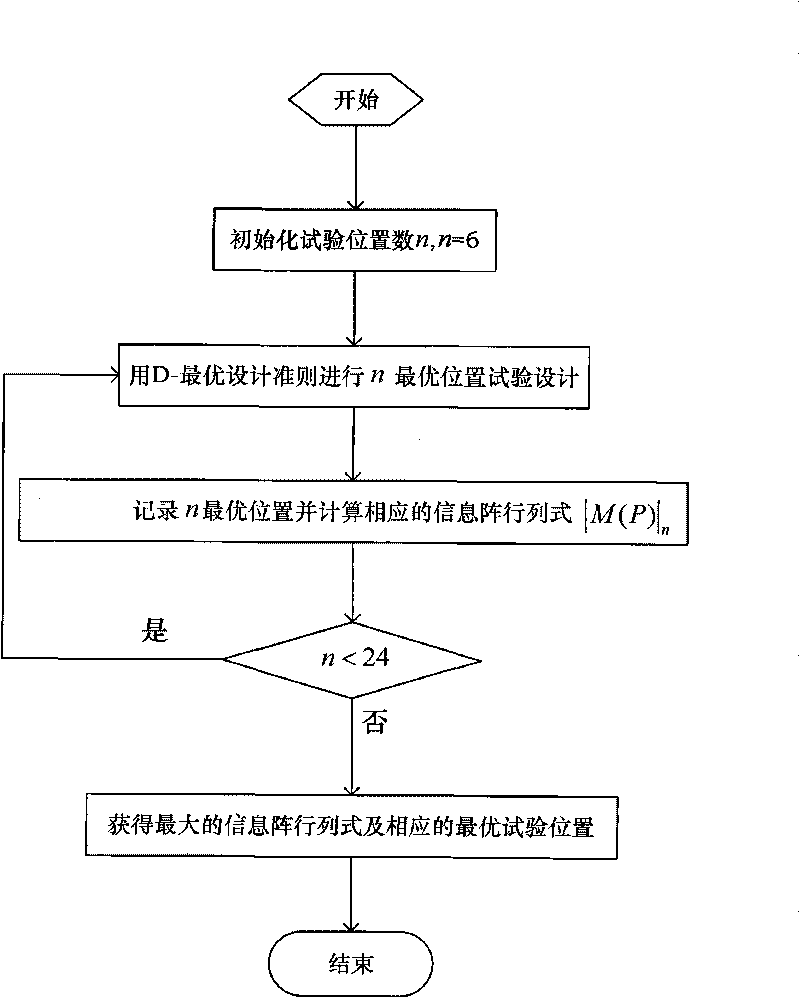

[0149] The present invention is a space orthogonal twelve position calibration method based on the DTGs-AID-ADD model, using the D-optimal experimental design method to determine that the number of optimal test positions for the DTGs-AID-ADD model should be twelve and the maximum Excellent twelve test orientation. Table 5 shows the drift coefficients obtained by testing the flexible gyroscope in the inertial navigation test center using the traditional eight-position method, the full-space orthogonal twenty-four-position method and the space orthogonal twelve-position method. Table 6 is the data of test points. These test points are taken from the full-or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com