Manufacturing mold of structural surface model in direct shear test

A structural surface and mold technology, applied in the engineering field, can solve problems such as poor fit between the upper and lower plates, high cost, and inability to make multiple scales, and achieve high-precision results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

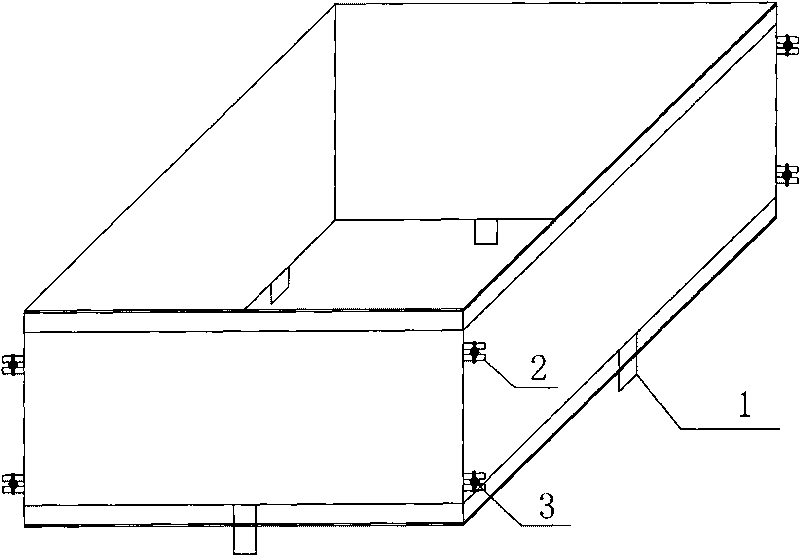

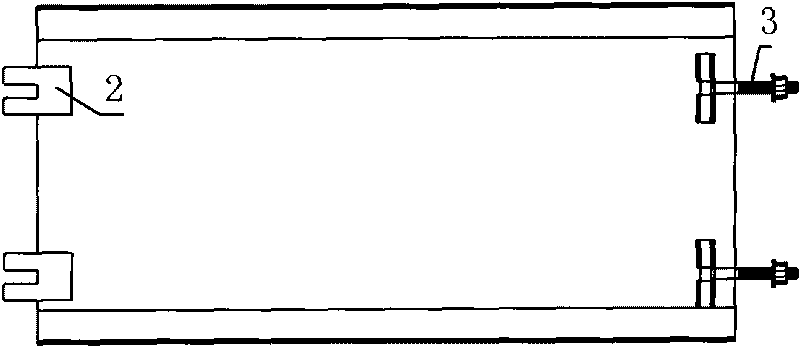

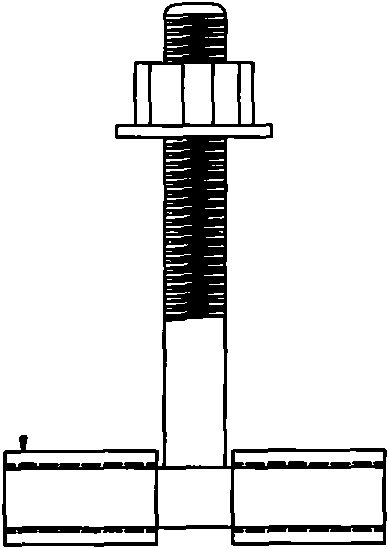

[0021] refer to figure 1 ~ Fig. 4, a kind of making mold of direct shear test structure surface model, comprises upper plate mold, lower plate mold and alignment pin, described upper plate mold is positioned on described lower plate mold, the side plate bottom surface of described upper plate mold There are positioning pins 1 for centering the upper plate mold and the lower plate mold. The upper plate mold includes an upper front side plate, an upper left side plate, an upper rear side plate and an upper right side plate. The upper plate mold forms The shape of the cavity matches the structural surface model of the upper plate to be made, the upper front side plate is fixedly connected with the upper left side plate and the upper right side plate, and the upper rear side plate is fixedly connected with the upper left side plate and upper right side plate The lower pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com