Automatic servo pressure regulating method and device of satellite-type flexible steel roller printing machine

An automatic servo, flexo roll technology, applied in printing presses, rotary printing presses, printing and other directions, can solve the problems of high work intensity, low pressure regulation efficiency, and single function of the pressure regulation system, and achieves the reduction of workers' work intensity, The effect of improving printing efficiency and stable print quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

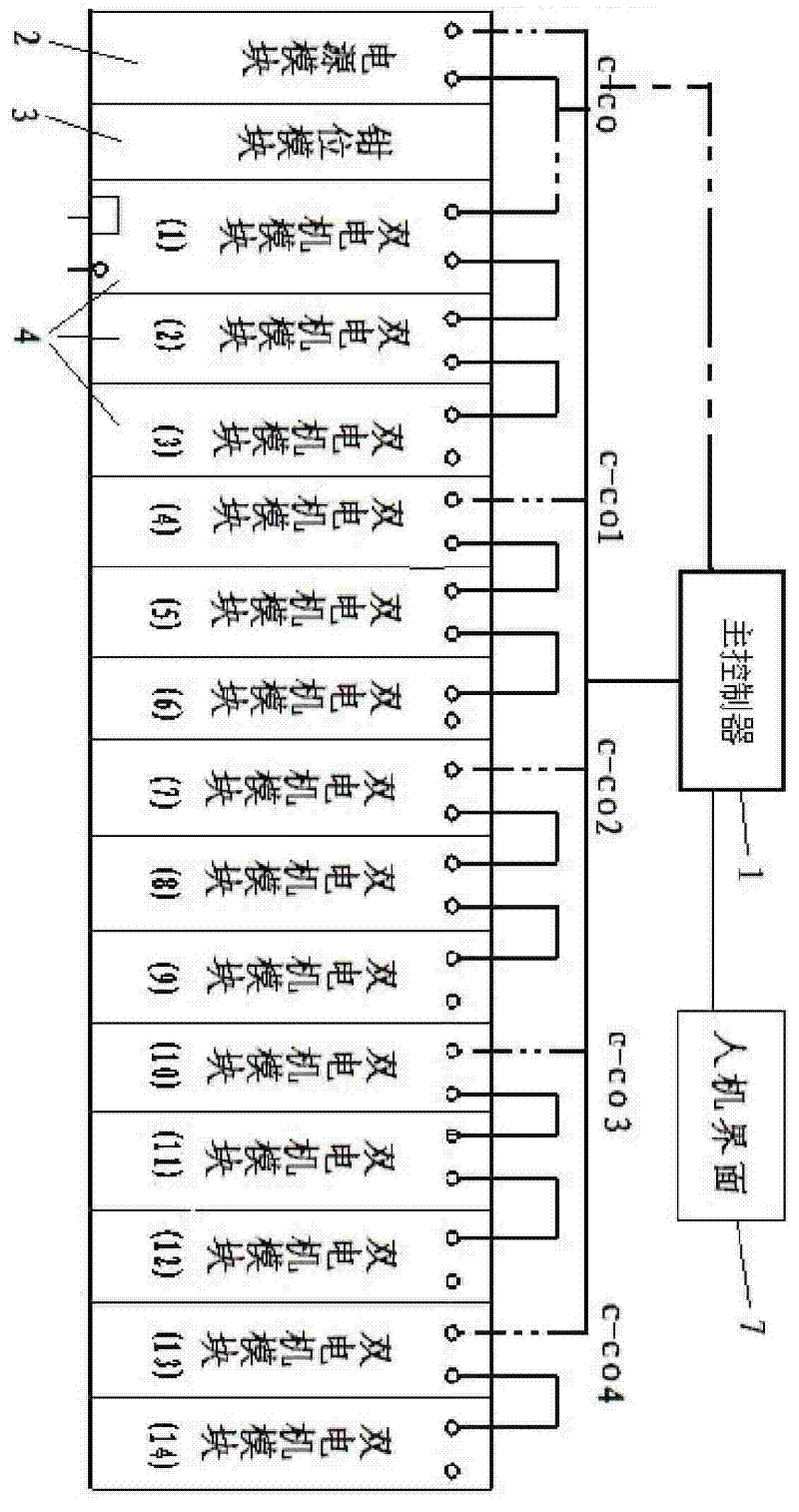

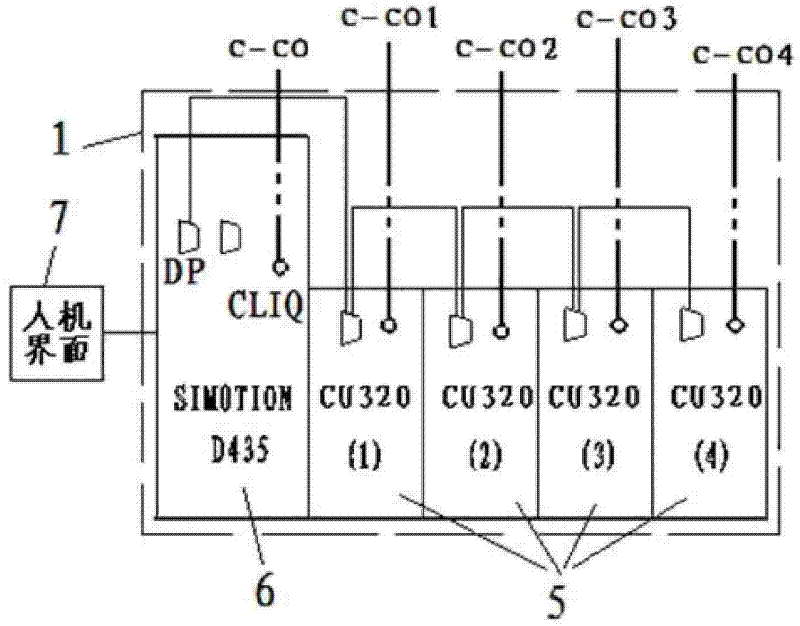

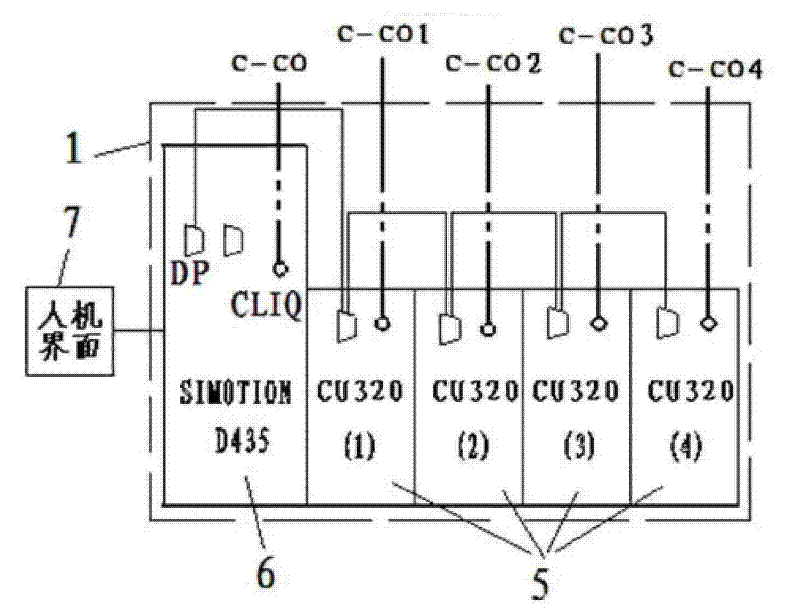

[0030] The invention discloses a control device structure for realizing the method of the invention, such as figure 1 As shown, it includes the main controller 1, the main controller 1 is connected with the power supply module 2 and the man-machine interface 7, the main controller 1 is respectively connected with the dual-motor drive module 4 of several groups of servo motors, and the servo motor adopts Siemens high-precision AC There are 14 groups of servo motors and dual-motor drive modules 4, which drive 28 servo axes in total. The 28 servo axes drive the connected servo motors and then connect with their respective plate roller seats. It is written for SIMOTION D435), the position and speed feedback signal of each servo axis is transmitted to the main controller 1 through the absolute encoder behind the servo motor, the main controller 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com