Method for arranging 220 kV and 110 kV interval secondary devices

A technology of secondary equipment and layout method, applied in the electrical field, to achieve the effect of simplified and clear interconnection, saving of connection medium, and reduction of room area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Both 220kV and 110kV substations of 220kV adopt GIS power distribution devices. The 220kV, 110kV protection measurement and control, merging unit, and intelligent unit are lowered to the GIS room, and they are combined with the GIS local control part to form a GIS intelligent control cabinet. According to the specific number of equipment in the interval, the 220kV GIS intelligent central control cabinet is designed according to the scheme in Table 1, and Table 1 is the layout plan of the GIS intelligent central control cabinet.

[0020] Table 1

[0021]

Number of cabinets

quantity

Cabinet layout

220kV

GIS

2 sides

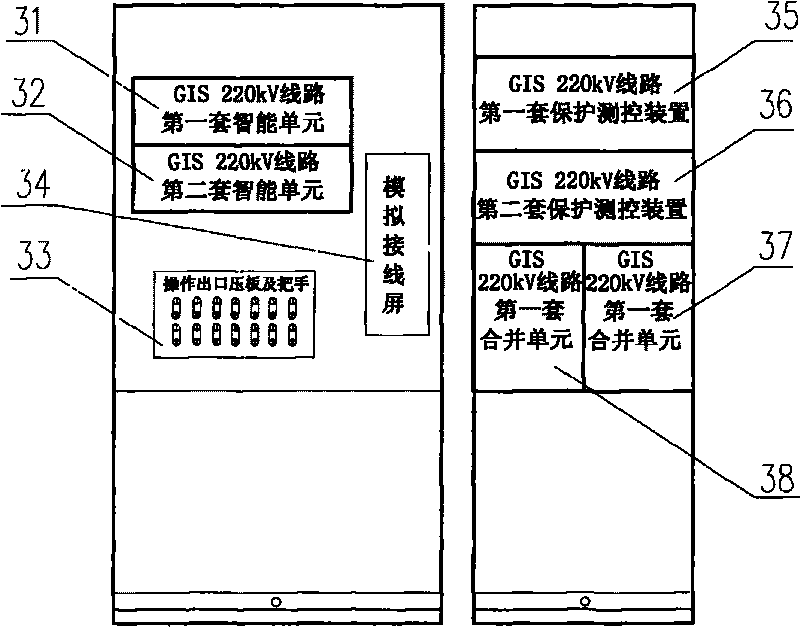

Cabinet 1: including 2 intelligent units, operation outlet pressure plate, operation handle, simulation

Wiring screen, etc.;

Cabinet 2: including 2 sets of protection measurement and control devices, 2 sets of merging units, etc.

110kV

GIS

1 side

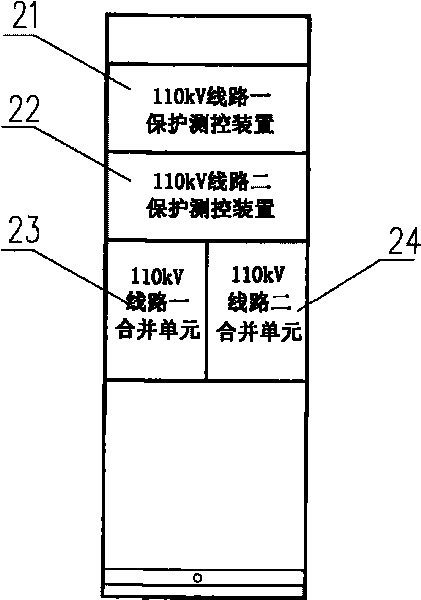

Including 1 protection measur...

Embodiment 2

[0030] Table 2 is the statistics of the number of screen cabinets after the screen cabinets are optimized and grouped according to the second embodiment.

[0031] Table 2

[0032] serial number

[0033] If the 220kV substation adopts the conventional panel scheme, about 108 panel cabinets are needed in the main control room, and according to the optimized panel scheme, only about 60 panel cabinets are needed, and the overall saving rate reaches 44%, saving 4 rows of panel cabinets and saving the main control room Room area 99m 2 .

Embodiment 3

[0035]220kV substation adopts AIS power distribution device. The 220kV interval group adopts an integrated protection, measurement and control device. With the lowering of the operation box, the removal of hard pressure plates, operating handles and other equipment in the cabinet, there are only 2 protection, measurement and control devices + 2 merging units left in a 220kV interval, so it is realized in space. 1 Arrangement in the panel cabinet. Table 3 is the statistics of the number of screen cabinets after the screen cabinets are optimized and grouped according to the third embodiment.

[0036] table 3

[0037] serial number

[0038] serial number

[0039] The 220kV substation requires about 124 screen cabinets according to the conventional screen assembly scheme, and only about 91 screen cabinets according to the optimized screen assembly scheme, with an overall saving of 27%, saving 3 rows of screen cabinets and saving room area of 69m 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com