Ink-absorption groove structure and paper bearing device

A carrier device and paper technology, applied in printing devices, printing, etc., can solve the problems of large deformation of paper, paper buckling, printer jams, etc., and achieve the goal of increasing reliability and durability, increasing transmission speed and fluency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

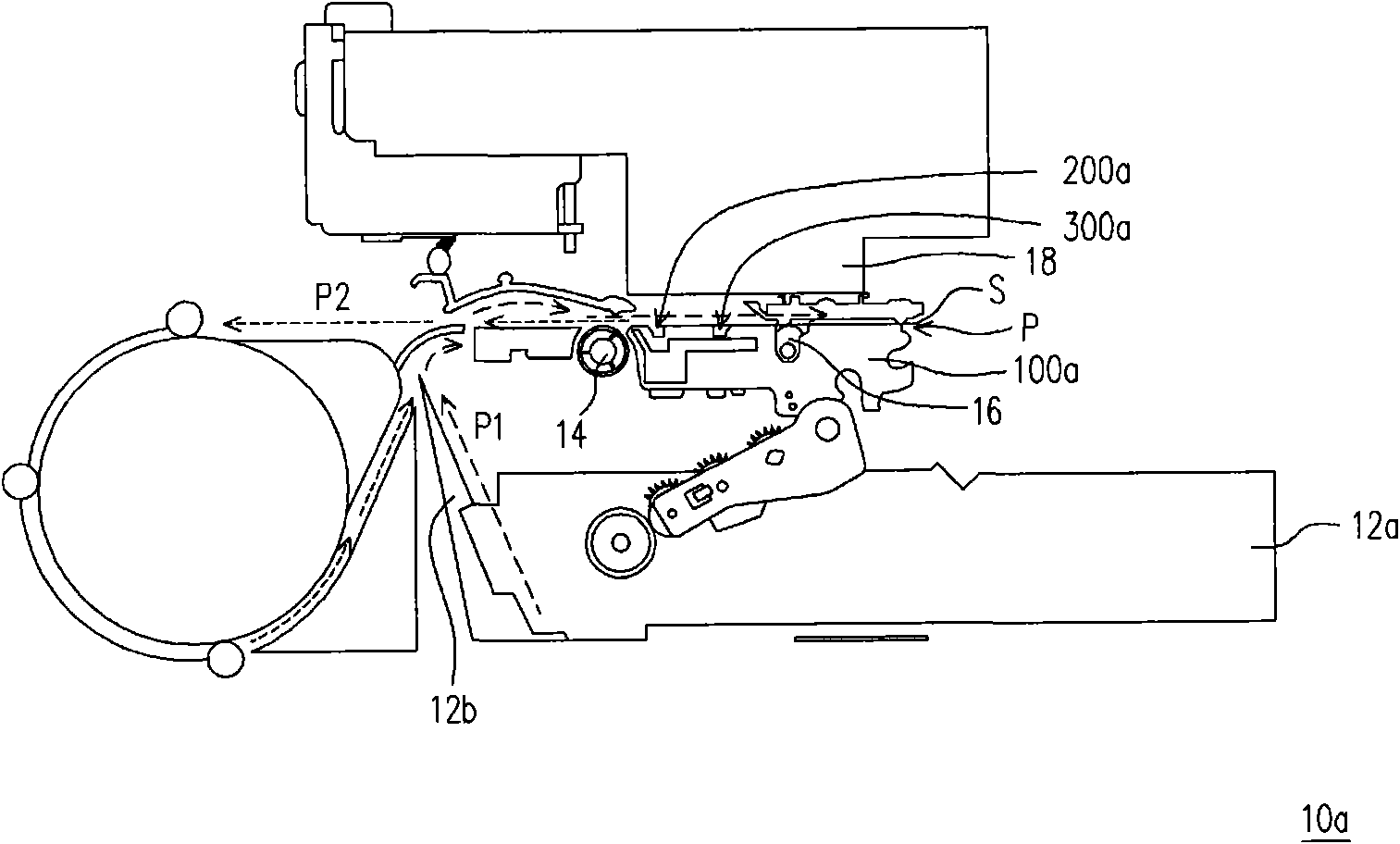

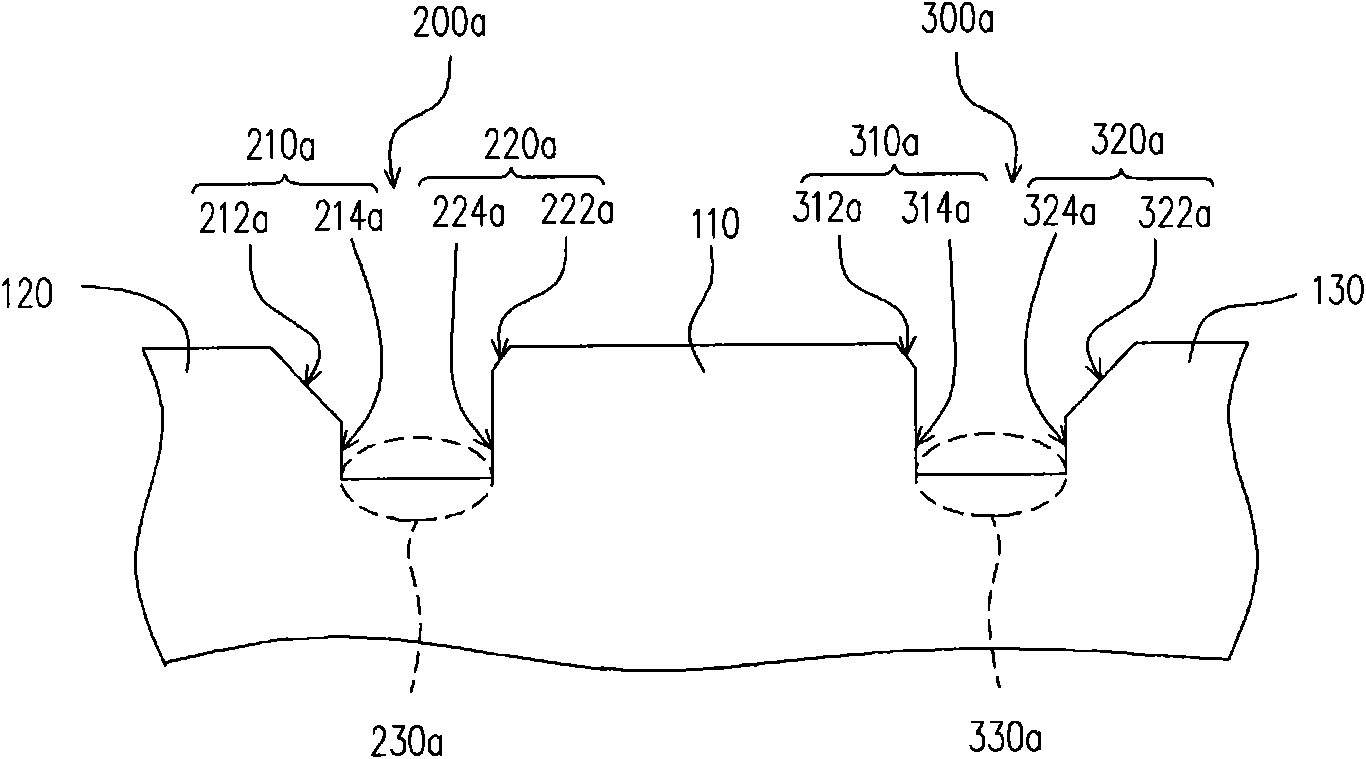

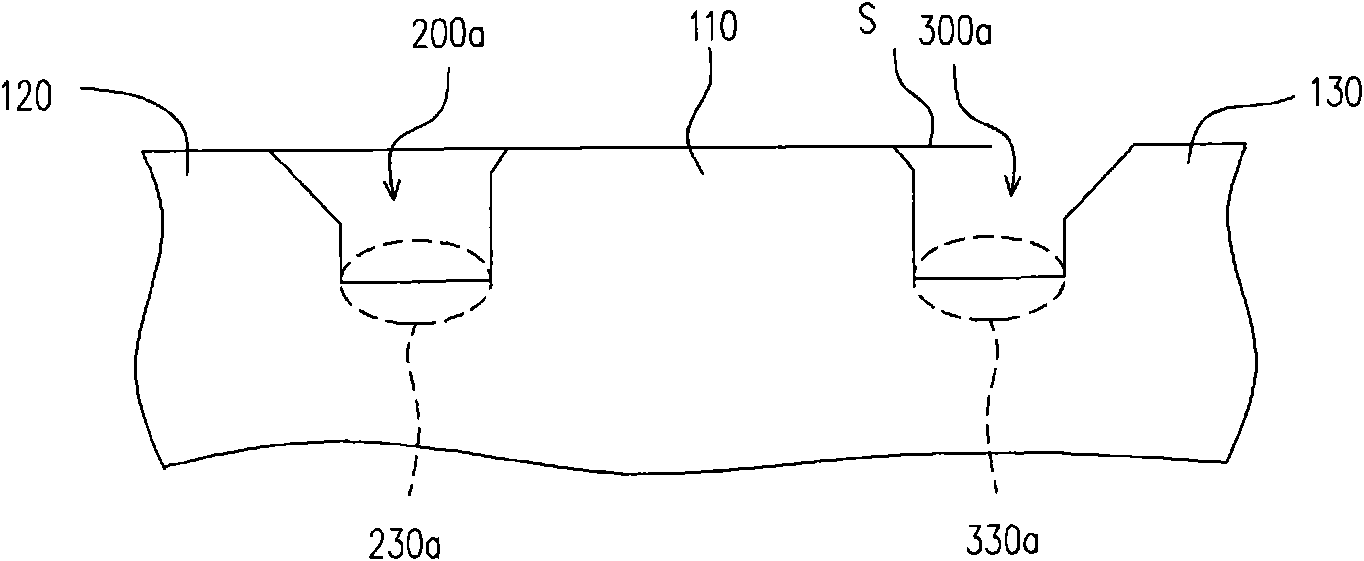

[0064] Figure 1A is a schematic diagram of a paper carrying device according to an embodiment of the present invention applied to a printer, Figure 1B yes Figure 1A The enlarged schematic diagram of the first ink-absorbing groove structure and the second ink-absorbing groove structure. It must be noted here that, for the sake of convenience, Figure 1B Some components are omitted from illustration. Please also refer to Figure 1A and Figure 1B , in this embodiment, the paper supporting device 100a is suitable for being assembled in a printer 10a to perform double-sided full-page printing on a paper S, wherein the design of the ink-absorbing groove structure can allow the full-page printing The paper S can be smoothly conveyed in the printer 10a.

[0065] The paper carrying device 100 a has a carrying area 110 , a first peripheral area 120 and a second peripheral area 130 , wherein the carrying area 110 is located between the first peripheral area 120 and the second peri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com