Cavity splitting device for injection forming mould

An injection molding and mold technology, applied in the field of injection molding molds, can solve the problems of affecting production efficiency, wasting manpower and time costs, etc., and achieve the effect of improving production efficiency and saving time for cavity division

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be described in detail below in conjunction with the accompanying drawings.

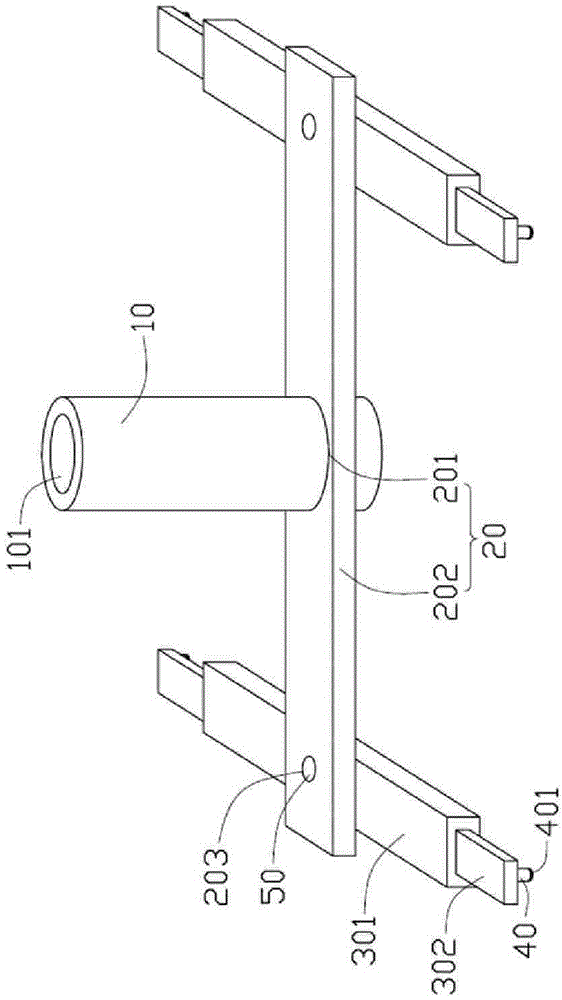

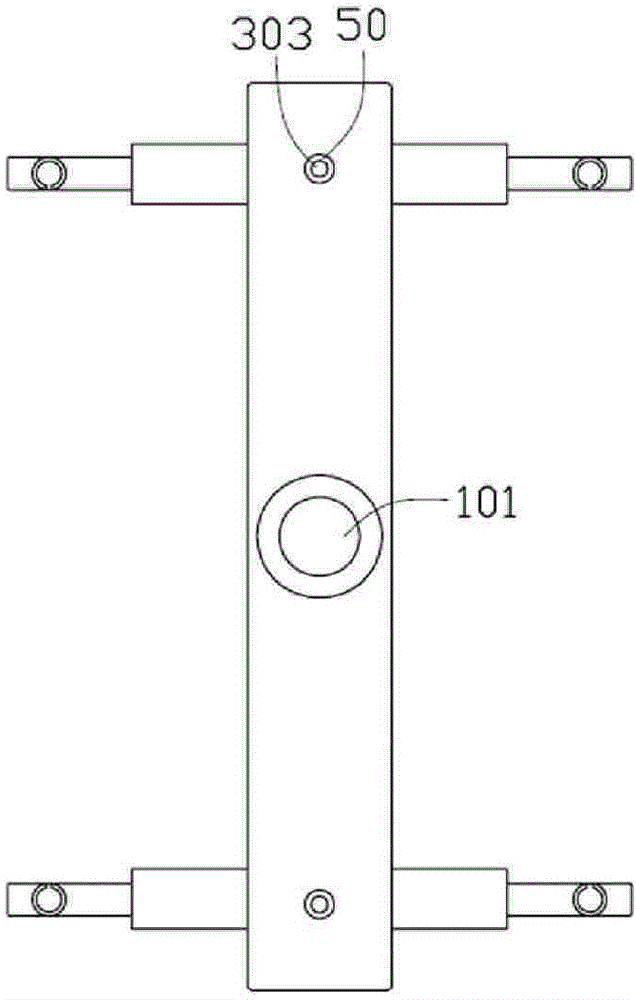

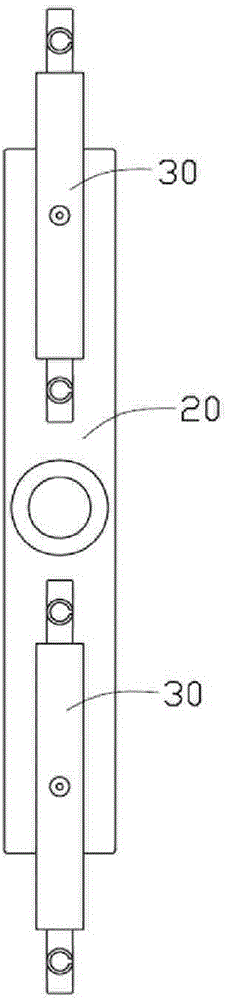

[0011] see figure 1 and figure 2 , the injection mold cavity dividing device includes a vertical bar 10, a horizontal bar 20 whose middle part is vertically fixed on the vertical bar 10, and two telescopic bars 30 respectively rotatably arranged at both ends of the horizontal bar 20, And a plurality of adsorption devices 40 respectively located at the ends of the telescopic rods 30 .

[0012] The bottom end of the vertical rod 10 defines a cavity 101 for accommodating the sprue head of the injection mold.

[0013] The horizontal bar 20 has a sleeve portion 201 and a rod portion 202 extending along both sides of the sleeve portion 201, the sleeve portion 201 is sleeved on the vertical rod 10, and the rod portion 202 is opposite to the Each end defines a first through hole 203 .

[0014] The telescopic rod 30 has a hollow sleeve rod 301 , and two ends of the hollo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com