Preparation method of meat flavor seasoning

A seasoning and meat-flavored technology, which is applied in the field of preparation of meat-flavored seasonings, can solve problems such as difficult large-scale industrial production, unfavorable product promotion, and poor taste of seasonings, and achieve good water solubility, wide application range, and various tastes Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

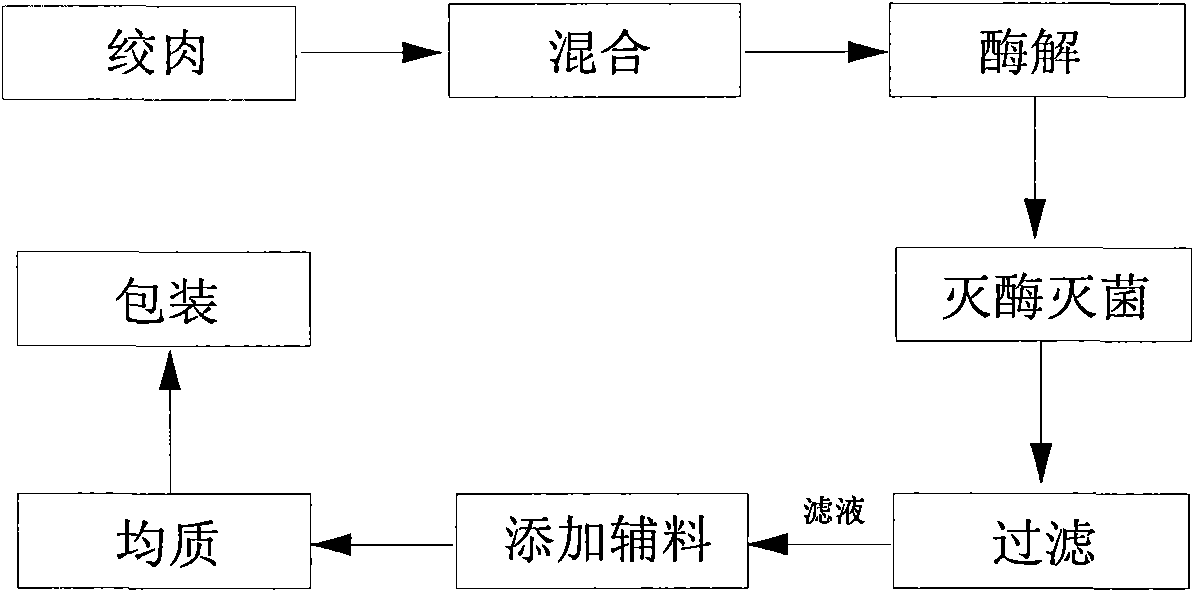

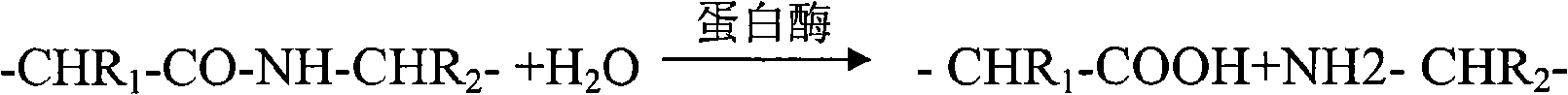

[0031] Embodiment 1: refer to figure 1 , the present embodiment provides a kind of preparation method of meat seasoning, and it directly uses beef, chicken and pork etc. as raw material, adopts directional enzymolysis technology, utilizes protease as biocatalyst, meat (chicken, pig, cattle etc. The protein in ) is decomposed into a hydrolyzate containing various amino acids and peptides, and then homogeneously added with auxiliary materials to make a sauce-like seasoning. The specific steps are as follows:

[0032] 1) Minced meat: Grind industrially produced frozen meat (frozen chicken, frozen beef, frozen pig, etc.) through a meat grinder;

[0033] 2) Mixing: put into the enzymolysis tank according to the weight ratio of meat: water=9:1, mix evenly, and make meat paste;

[0034] 3) Enzymolysis: Add biological enzymes to the hydrolysis tank according to the weight ratio of meat: enzyme = 1000: 0.1, heat to 35-75°C while stirring, control the stirring speed to 20-100 rpm, and ...

Embodiment 2

[0037] Embodiment 2: refer to figure 1 , the preparation method of a kind of meat seasoning provided by the present embodiment, its specific steps are as follows:

[0038] 1) Minced meat: Grind industrially produced frozen meat (frozen chicken, frozen beef, frozen pig, etc.) through a meat grinder;

[0039] 2) Mixing: put into the enzymolysis tank according to the weight ratio of meat: water = 9: 2, mix evenly, and make meat paste;

[0040] 3) Enzymolysis: Add biological enzymes to the hydrolysis tank according to the weight ratio of meat: enzyme = 1000: 0.8, heat to 35-75°C while stirring, control the stirring speed to 20-100 rpm, and the enzymolysis reaction is 0.5-75°C. After 10 hours, raise the temperature to 80-100°C, inactivate the enzyme, and sterilize;

[0041] 4) Filtration: put the reaction solution in the hydrolysis tank into a vibrating filter for filtration, discard the residue to obtain a filtrate, and put the filtrate into a cold and hot cylinder for heat pres...

Embodiment 3

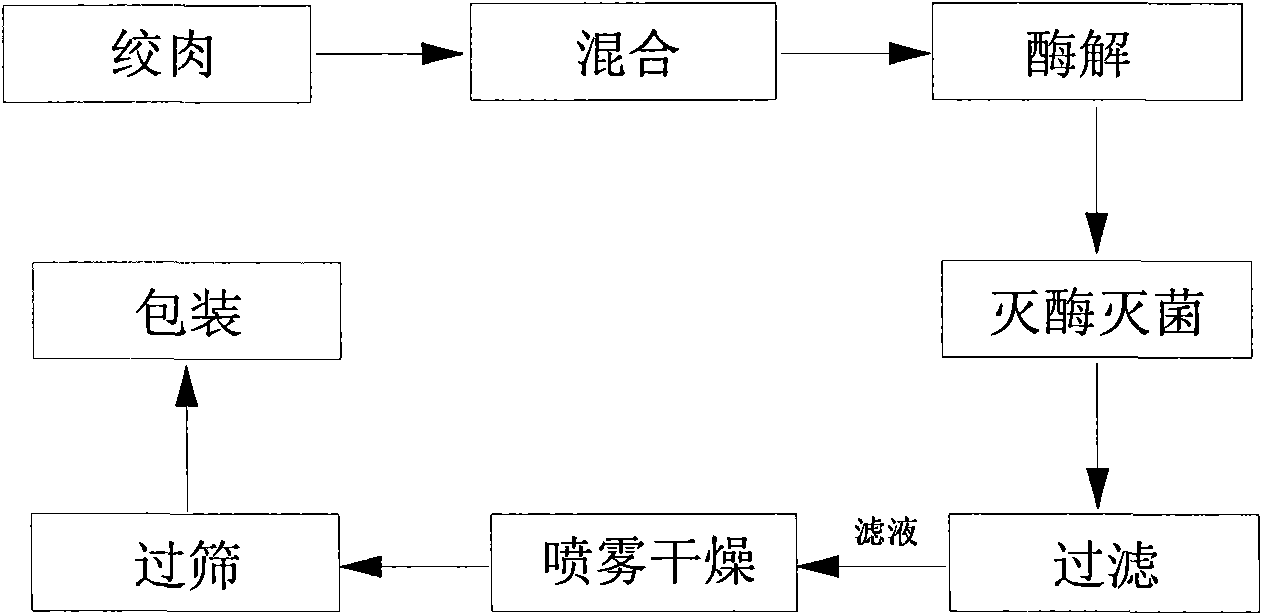

[0043] Embodiment 3: refer to figure 1 , the preparation method of a kind of meat seasoning provided by the present embodiment, its specific steps are as follows:

[0044] 1) Minced meat: Grind industrially produced frozen meat (frozen chicken, frozen beef, frozen pig, etc.) through a meat grinder;

[0045] 2) Mixing: put into the enzymolysis tank according to the weight ratio of meat: water=9:3, mix evenly, and make meat paste;

[0046] 3) Enzymolysis: Add biological enzymes into the hydrolysis tank according to the weight ratio of meat: enzyme = 1000:5, heat to 35-75°C while stirring, control the stirring speed to 20-100 rpm, and enzymolysis reaction is 0.5-75°C. After 10 hours, heat up to 80-100°C, inactivate the enzyme, and sterilize;

[0047] 4) Filtration: put the reaction solution in the hydrolysis tank into a vibrating filter for filtration, discard the residue to obtain a filtrate, and put the filtrate into a cold and hot cylinder for heat preservation at 65-85°C; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com