Component supplying device and surface mounter

A component supply and component technology, applied in the direction of electrical components, electrical components, etc., can solve the problems of unfavorable strip storage box compactness, component supply device transportation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

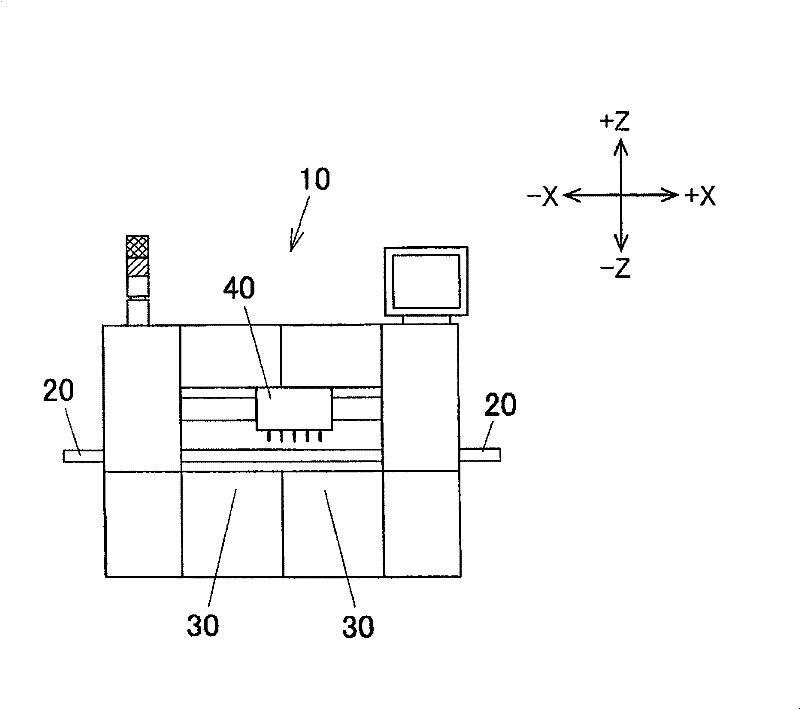

[0038] Next, a surface mounter according to a first embodiment of the present invention will be described with reference to the drawings.

[0039] 1. Overall structure

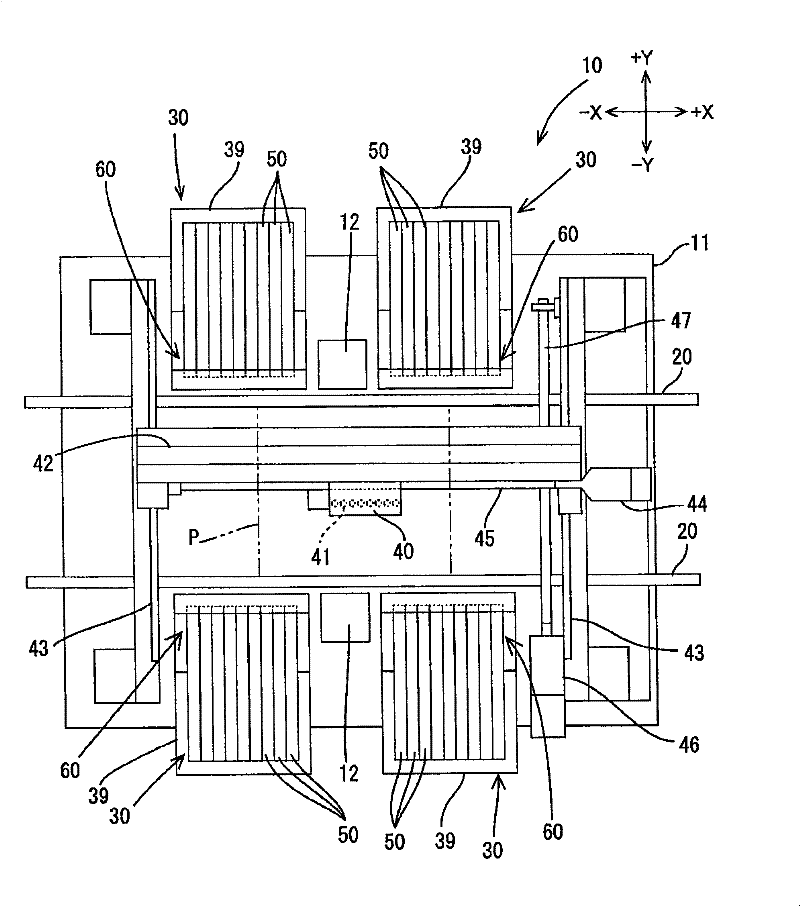

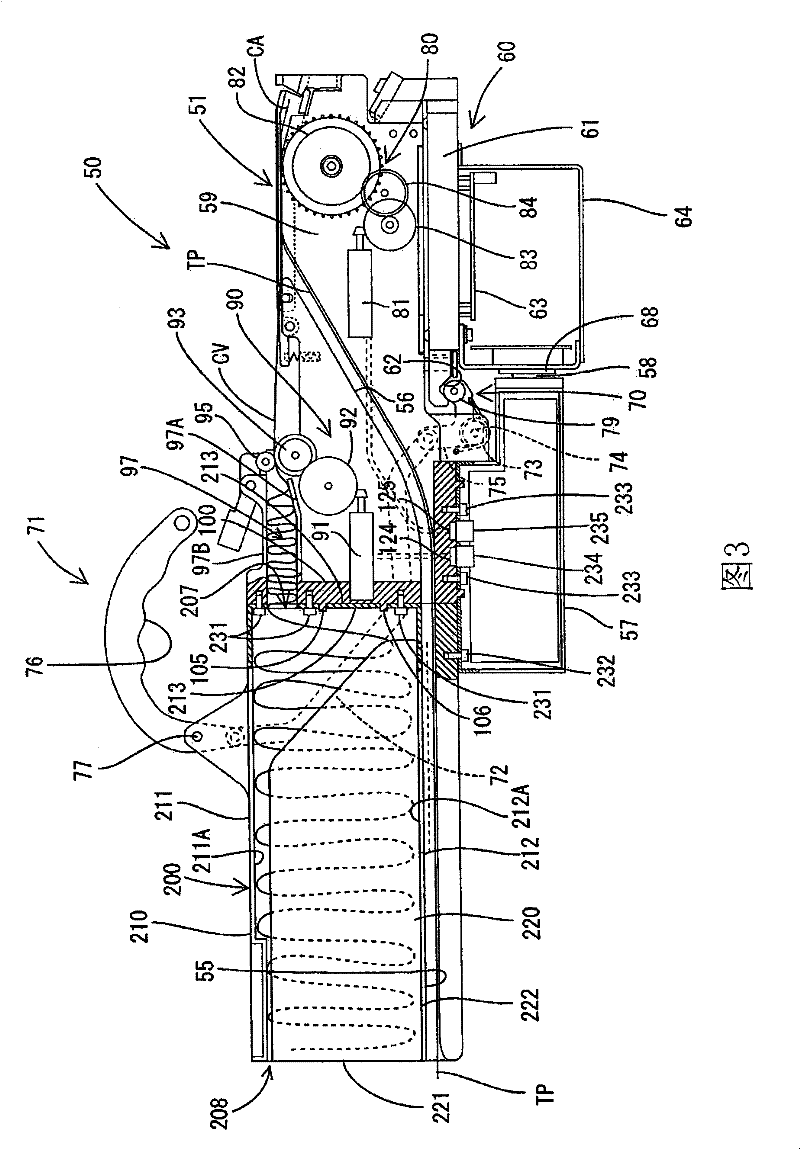

[0040] Such as figure 1 , figure 2 As shown, the surface mounter 10 includes; the conveyor belts 20, 20 arranged on the base 11 and used to transport the printed substrate P; the component supply parts 30 arranged on both sides of the conveyor belts 20, 20; above and used to install the head assembly 40 of electronic components.

[0041] The head assembly 40 is movable over an area between the component supply part 30 and the mounting position on the substrate P to take out electronic components from the component supply part 30 and mount them on the substrate P. As shown in FIG. Specifically, the head unit 40 is supported on a head unit support member 42 extending in the X-axis direction (the direction in which the conveyor belt 20 conveys the substrate) and can move along the X-axis direction. The head u...

no. 2 approach

[0091] Next, a second embodiment will be described. Figure 13 , Figure 14 It is a schematic diagram which shows the tape storage box used for the components supply apparatus of 2nd Embodiment. In the drawings, the same reference numerals are assigned to the same structures as those of the first embodiment, and detailed description thereof will be omitted. This also applies to other embodiments described later.

[0092] Such as Figure 13 , Figure 14 As shown, a retention mechanism 260 is provided within the strap storage box 200 . The holding mechanism 260 is used to hold (hold) the second case portion 220 at a predetermined position, and release the hold when a pressing force is applied to the second case portion 220 in a direction in which the storage volume expands. Specifically, the holding mechanism 260 is constituted by the metal plate 262 and the magnet 261. When the storage capacity of the cover tape CV in the tape storage box 200 is small, the second case part 2...

no. 3 approach

[0099] Next, a third embodiment will be described. Figure 15 shows the tape storage box used in the component supply device of the second embodiment, Figure 16 instantiated with Figure 15 Different strip containment boxes. In the third embodiment, the difference from the first embodiment is that the outer wall surface of the second case part 220 adopts a different structure from the first embodiment, and the rest of the structure is basically the same as the first embodiment. Wherein, in the tape storage box 200 of this embodiment, the shape, pattern, color and combination thereof of the outer wall surface of the second case part 220 are different from the outer wall surface of the first case part 210 so as to make it conspicuous. .

[0100] exist Figure 15 In the structure, the color of the outer wall surface of the second case part 220 is different from the color of the outer wall surface of the first case part 210, and in the state where the storage volume of the ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com