Belt-retracting device for tightener

A technology of retracting and unwinding belts and tightening, which is used in transportation and packaging, vehicles used for freight, and parts of bundling machinery, etc., which can solve the problems of too small tensioning force of lashing belts, influence of cargo transportation, and insufficient bundling. , to achieve the effect of moderate tension, easy operation, convenient use and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

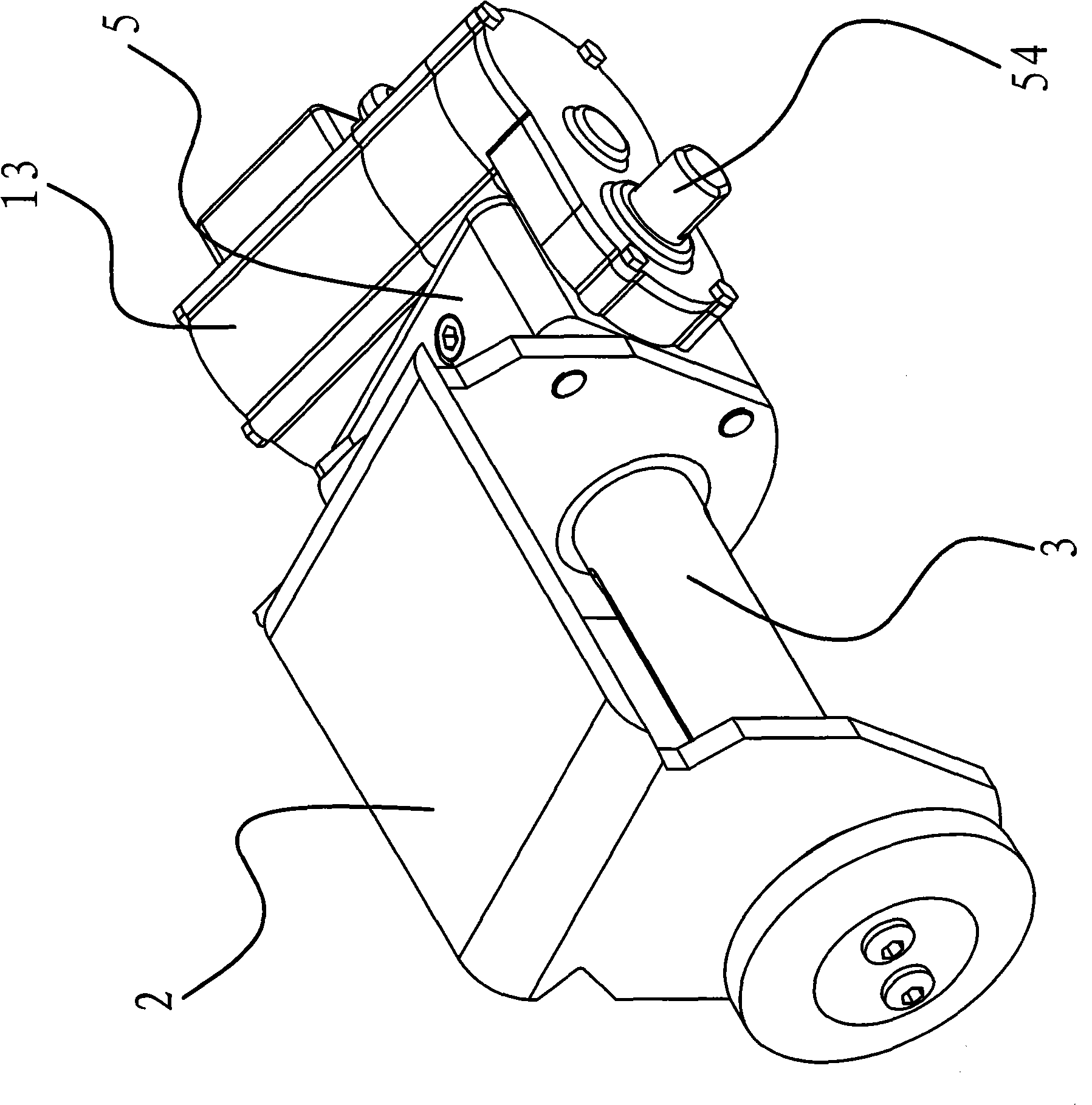

[0034] Such as figure 1 As shown, the tightener has a support 2 on which a belt shaft 3 is connected, and one end of the belt shaft 3 protrudes from the support 2 and is connected with a retractable belt device.

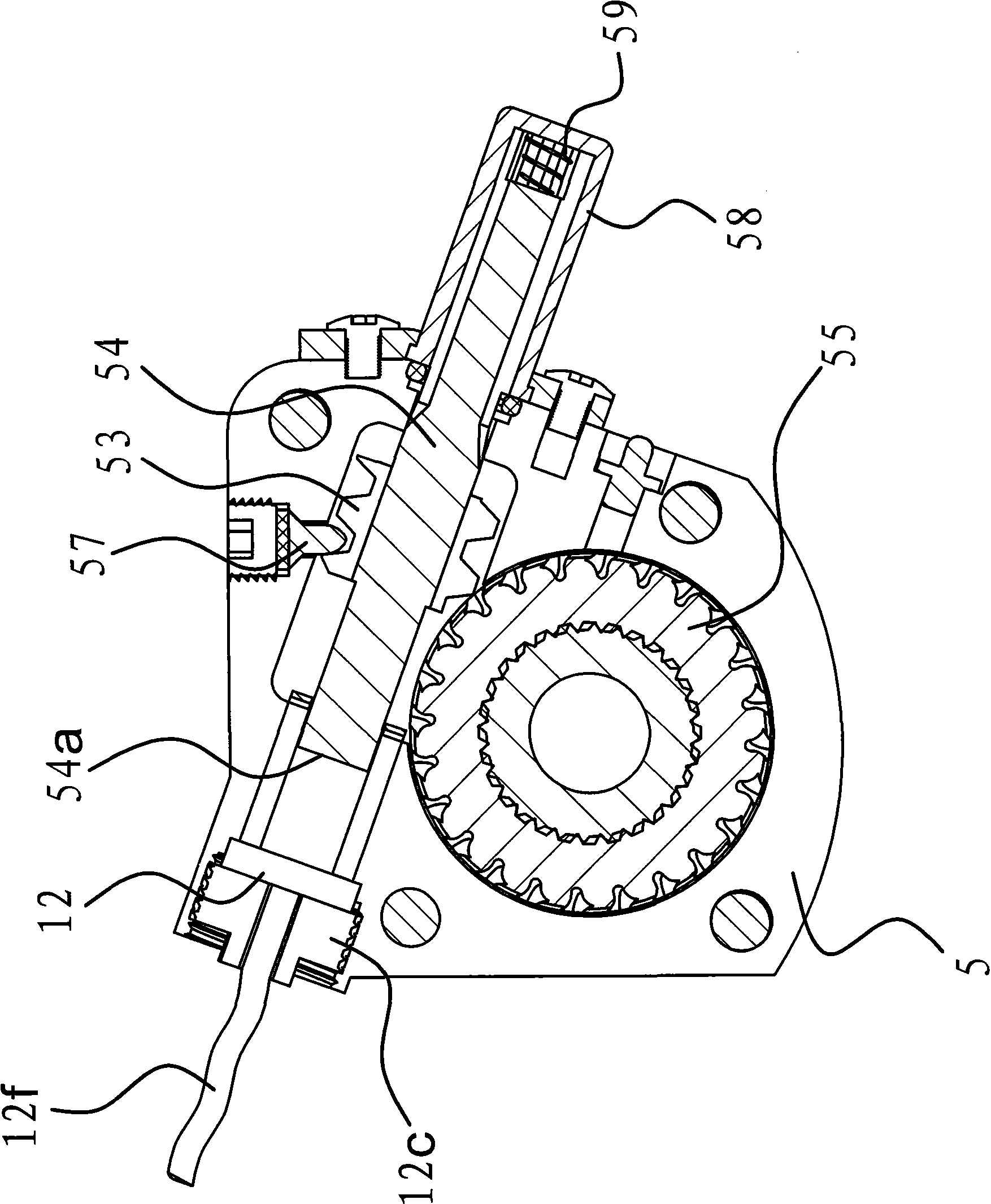

[0035] Such as figure 2 and image 3 Shown, this tightener take-up belt device comprises parts such as casing 5, worm screw 53, worm shaft 54, worm wheel 55, sensor 12, locator 57, rotating sleeve 58, spring 59.

[0036]A box body 5 with a cavity inside is fixedly attached to the side of the bracket 2 , and a worm 53 , a worm shaft 54 and a worm wheel 55 are arranged in the box body 5 . The worm 53 is sleeved on the worm shaft 54 and the two are fixedly connected together. Of course, the worm 53 and the worm shaft 54 here can also adopt an integrated structure. The worm wheel 55 is fixedly connected to the protruding end of the belt shaft 3 , and the worm shaft 54 is arranged on the side of the worm wheel 55 and can move in the casing 5 along its axial di...

Embodiment 2

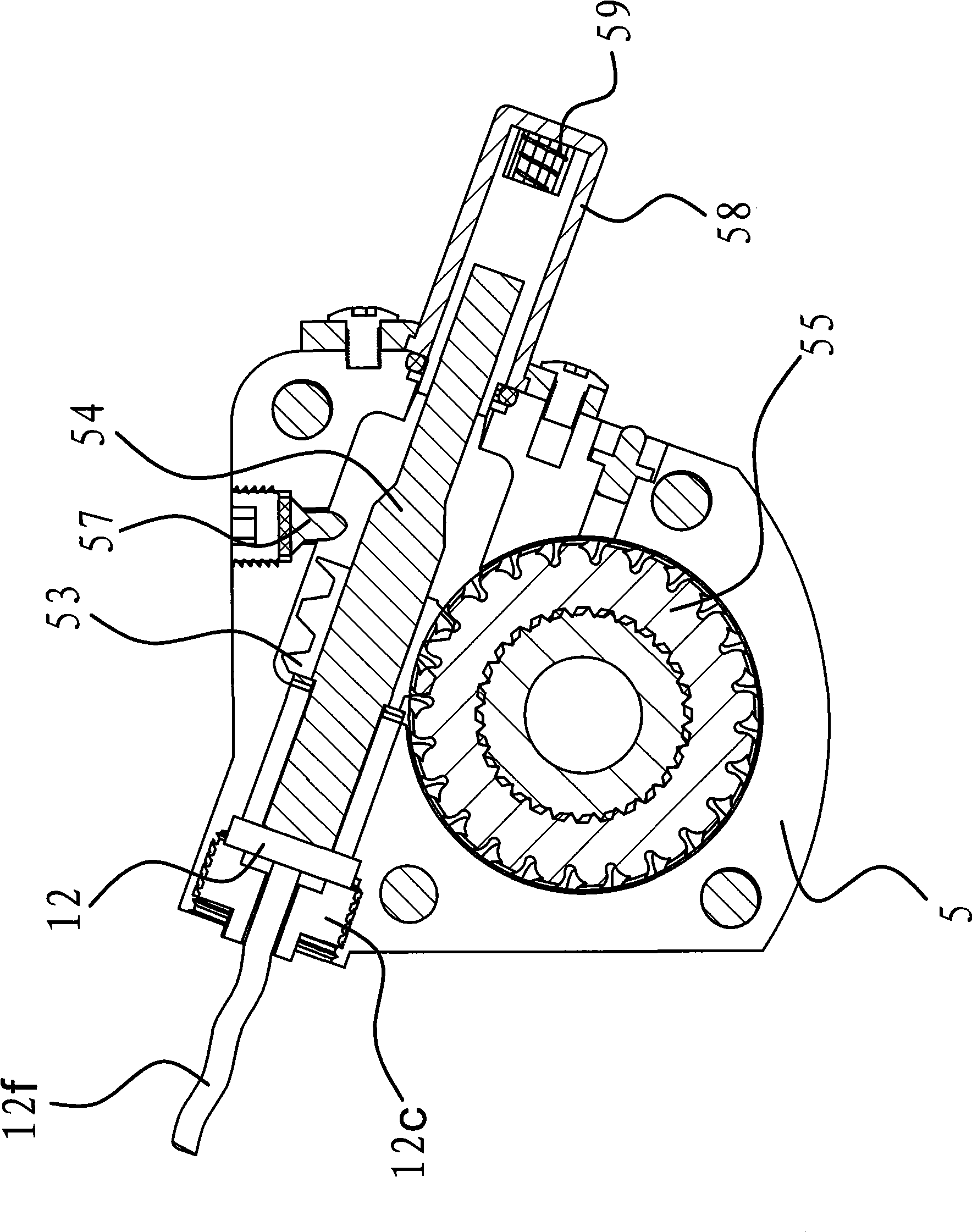

[0043] In this example, if Figure 4 and 5 As shown, a guiding mechanism capable of driving the worm shaft 54 to move along its axial direction is provided between the box body 5 and the worm 53 when the worm shaft 54 rotates. The guiding mechanism is a threaded connection section 61 provided on the worm shaft 54 and a threaded connection hole 62 provided on the box body 5, and the threaded connection section 61 and the threaded connection hole 62 can be threadedly connected, when the worm shaft 54 moves along its axial direction The rear worm 53 is engaged with the worm wheel 55 and the threaded connection section 61 is disengaged from the threaded connection hole 62 . The rest are similar to those in Example 1, and will not be described in detail.

[0044] When the threaded connection section 61 is connected with the threaded connection hole 62 , it can be moved along the thread during the process of turning the worm shaft 54 . Once the threaded section 61 of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com