Sewing umbrella fabric pliers

A technology of umbrella surface and working surface, applied in the direction of walking sticks, etc., can solve the problems of lower production efficiency, high labor cost, increase of product cost, etc., and achieve the effect of improving production efficiency, reducing manufacturing cost, and reducing labor expenditure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

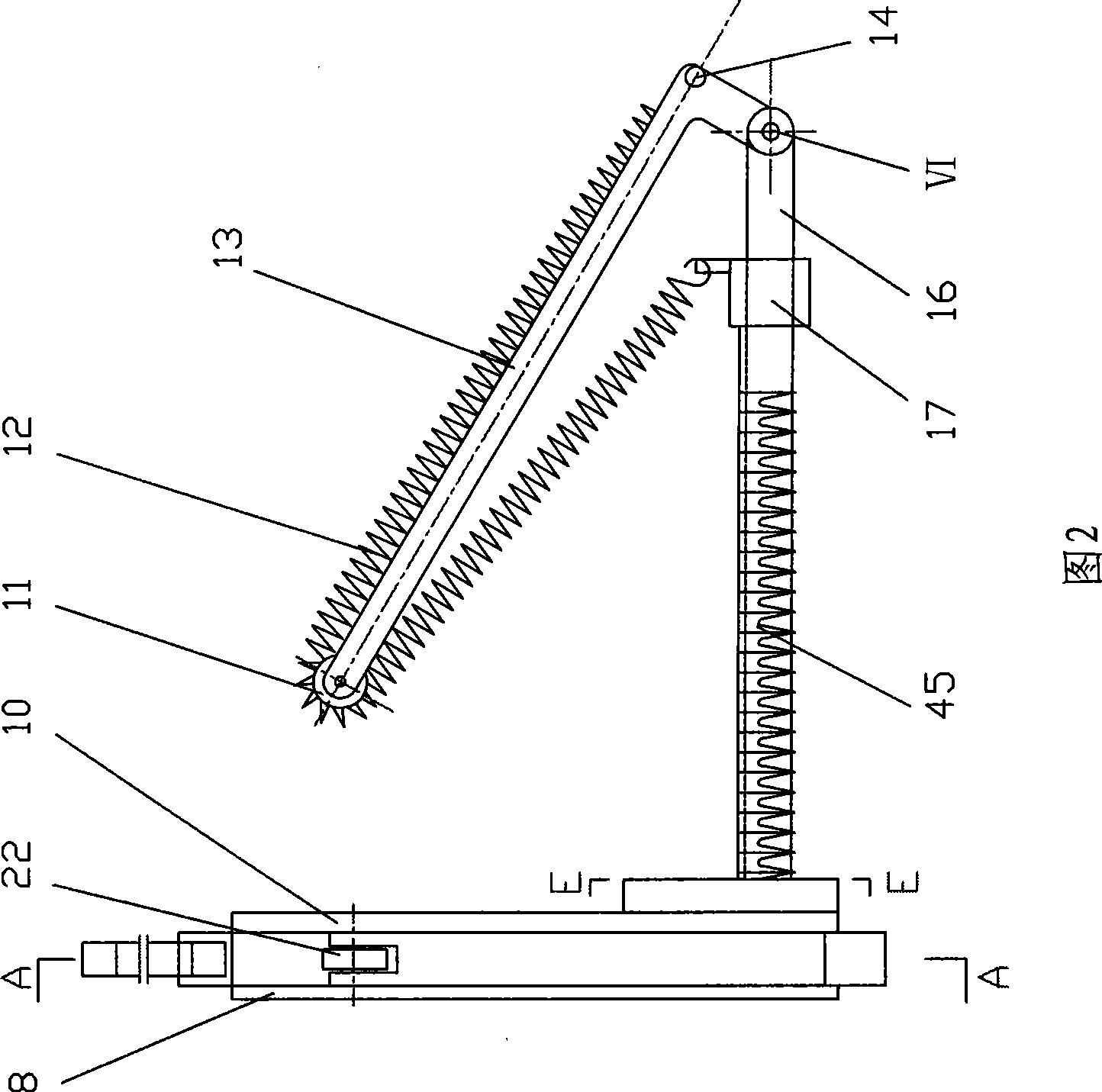

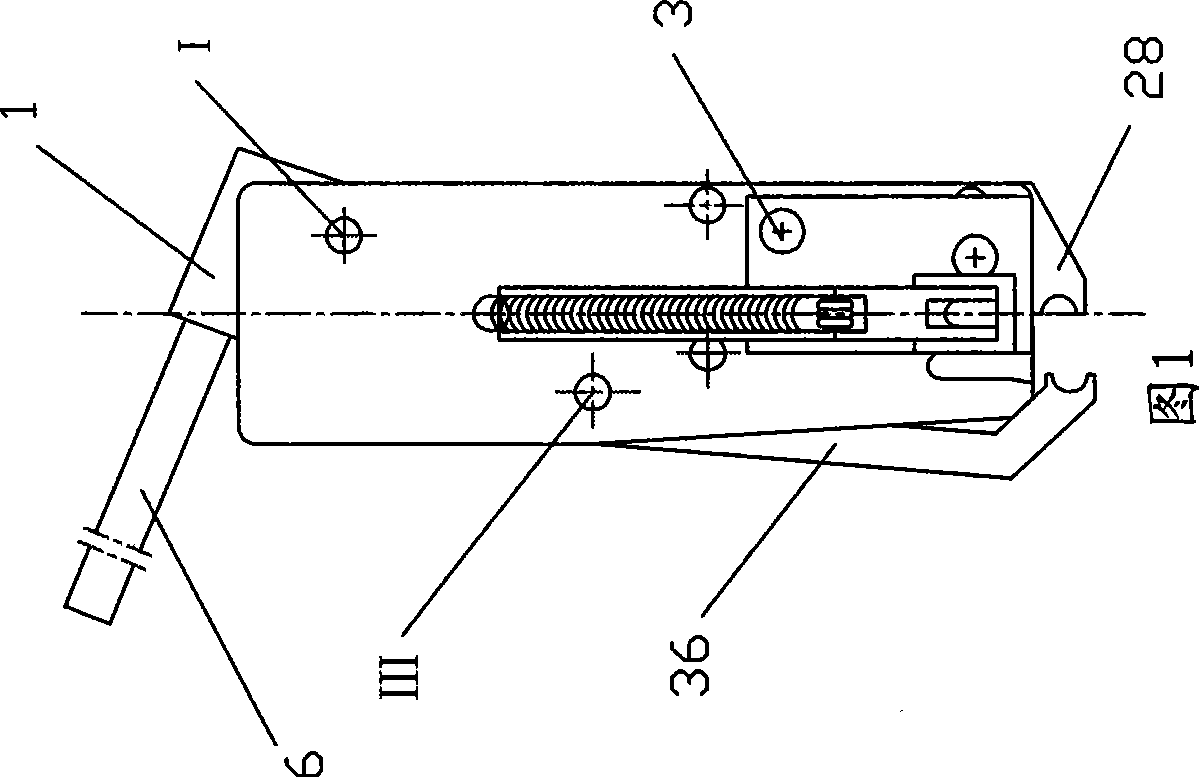

[0032] With reference to accompanying drawing, suturing canopy pliers of the present invention comprises base plate 8 and loam cake 10, and described base plate 8 is provided with:

[0033] A cam 1, pivotally connected to the axis I, has a first working surface E and a second working surface D at the bottom;

[0034] a handle, set on the cam 1;

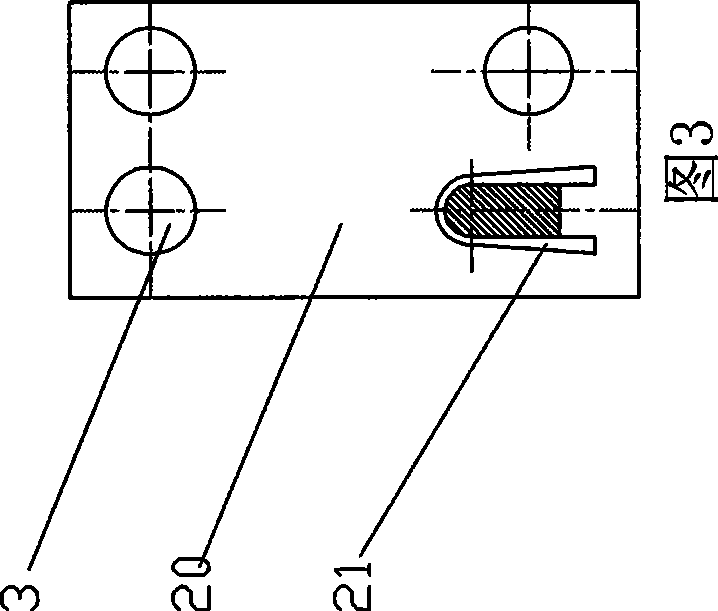

[0035] A fixed jaw 28, the inner side of the bottom end is provided with the first semicircle hole 42, and the described fixed jaw 28 is provided with a longitudinal compression spring hole 23, and this longitudinal compression spring hole 23 is a through hole, and the bottom of the through hole is provided with a Only tight fitting plug 29 blocks stage clip;

[0036] A movable jaw 36 is pivotally connected to the shaft III, and a second semicircular hole 41 opposite to the first semicircular hole 42 is provided on the inner side of the bottom end, and the upper end of the movable jaw 36 is pivotally connected to the second roller th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap