Structure for preventing large-sized aluminum cell case from deforming

An aluminum electrolytic cell and cell shell technology is applied in the structural field of preventing the deformation of the large aluminum electrolytic cell shell, which can solve the problems affecting the production and operation of the electrolytic cell, and achieve the effect of preventing the damage of the cathode, being easy to realize, and facilitating the production and operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

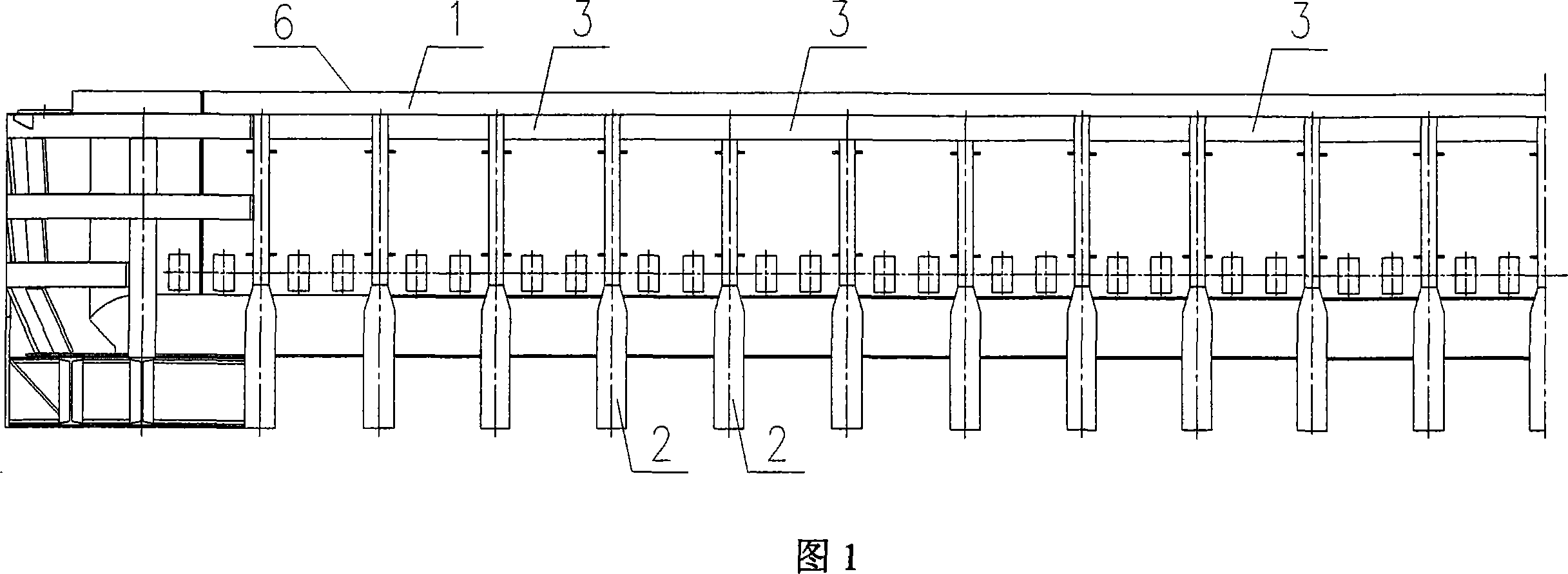

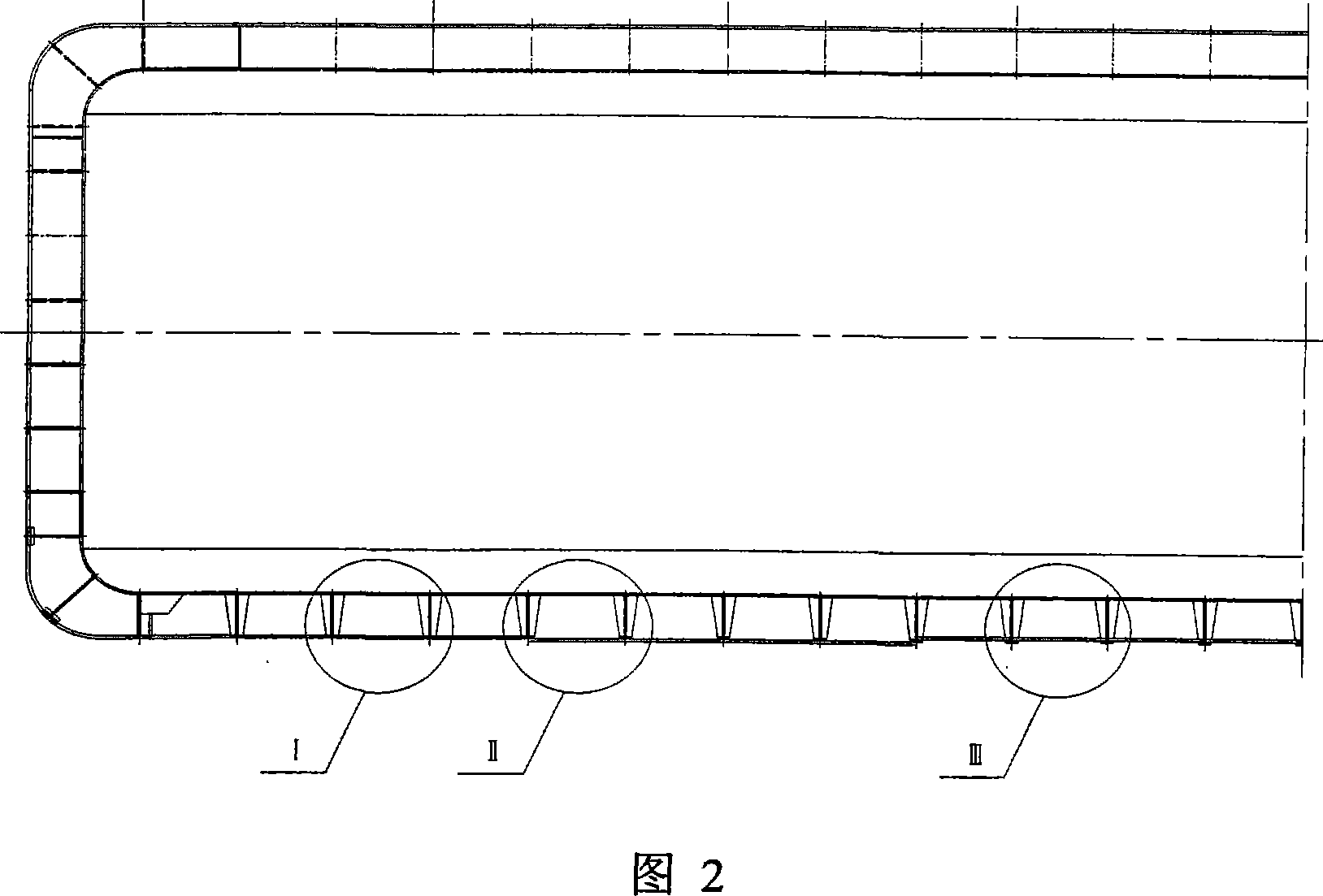

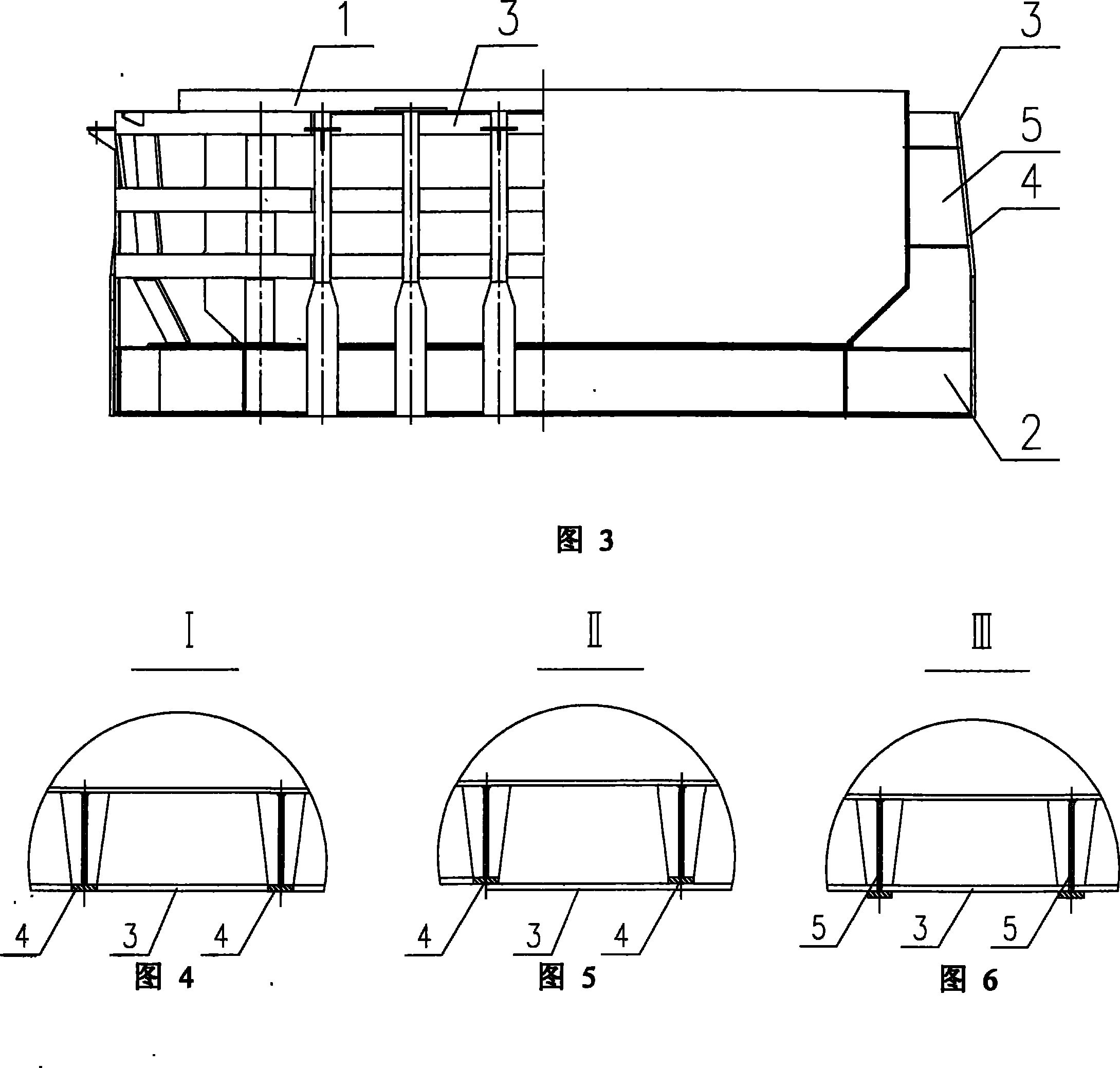

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0023] Such as Figure 1-Figure 3 As shown, the shroud 3 is connected between the cradle frame 2 of the electrolytic cell shell 1 . The girdle 3 can be connected to two adjacent cradle stands 2, and can also be connected to a plurality of cradle stands 2 at the same time. Such as Figure 4-Figure 6 As shown, the shroud 3 can be welded between the wing plates 4 of two adjacent cradle frames, and can also be welded between the vertical plates 5 of two adjacent cradle frames, so that its upper end should be as close to or as close to the upper edge of the tank shell as possible. Mouth 6 flush.

[0024] For the 280kA~700kA large-capacity aluminum electrolytic cell, the whole formed by the cradle frame 2 and the shroud 3 can be closed or open.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com