Method for appraising X-ray detection weld joint K value by utilizing overlap joint mark article

An X-ray and marker technology, which is applied in the field of X-ray inspection, can solve the problem of whether the welding seam fixed film meets the requirements without qualitative analysis, etc., and achieves the effect of simple and intuitive evaluation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] This embodiment is used to explain the claims of the present invention, and the protection scope of the present invention is not limited to the following embodiments.

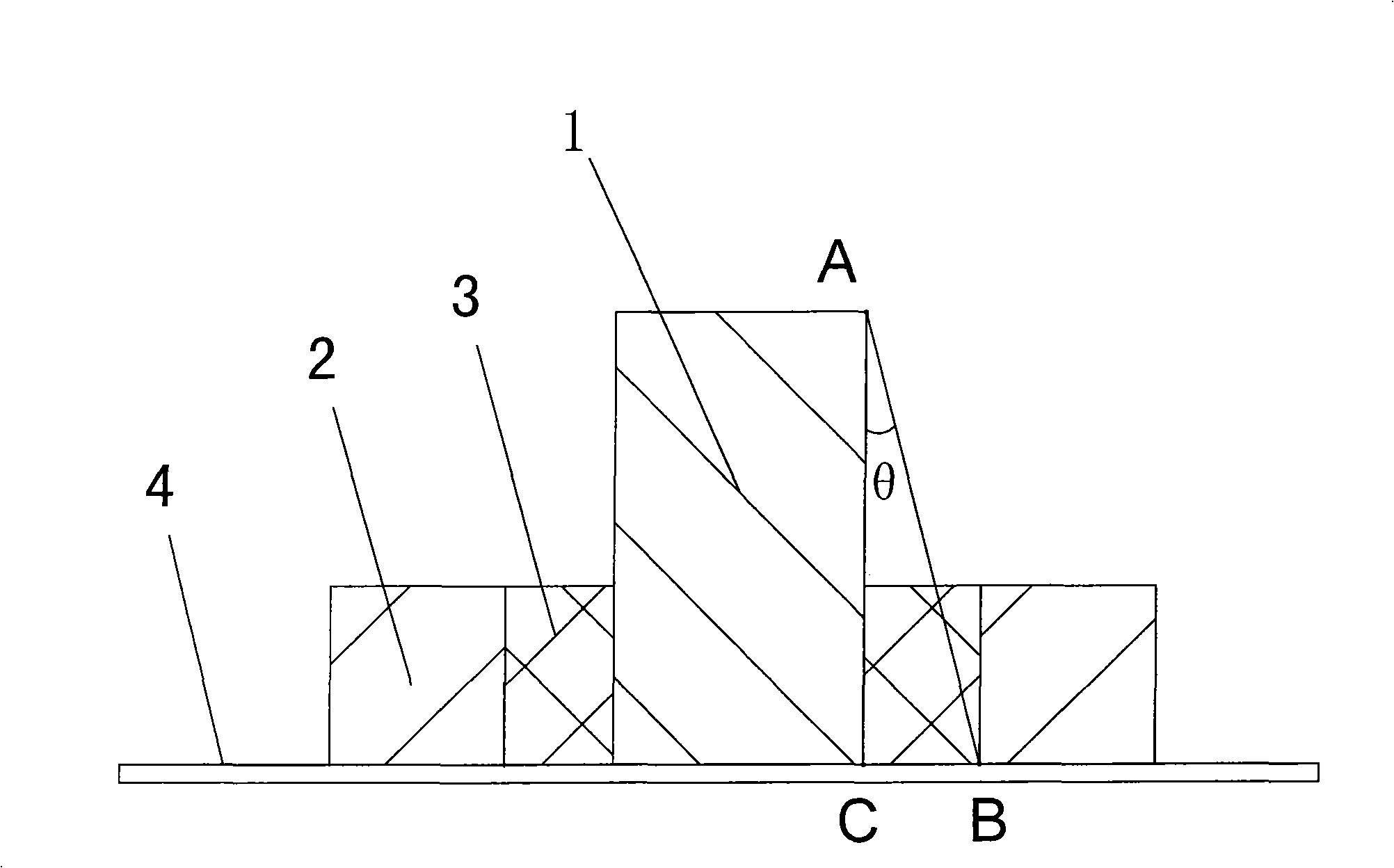

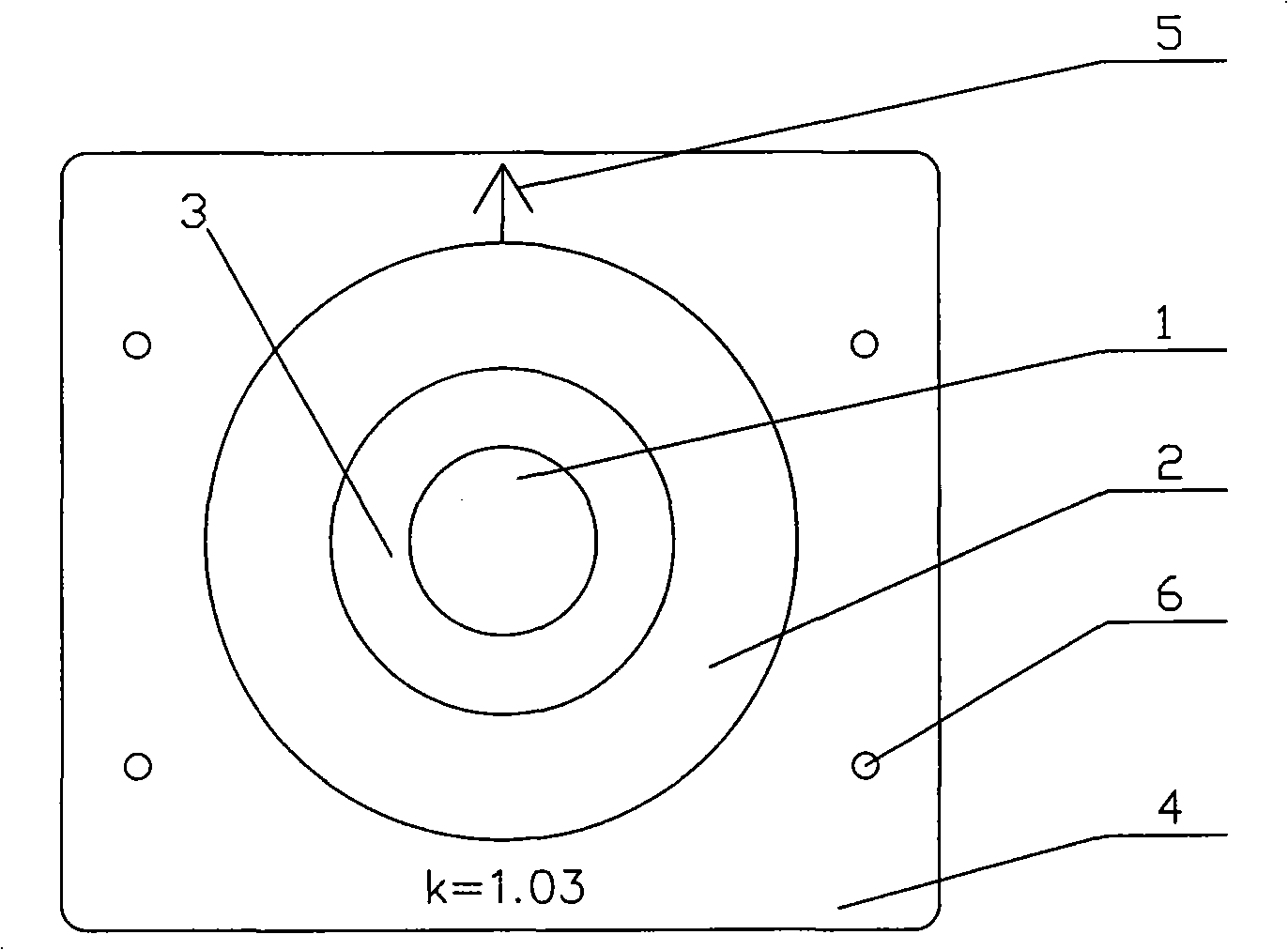

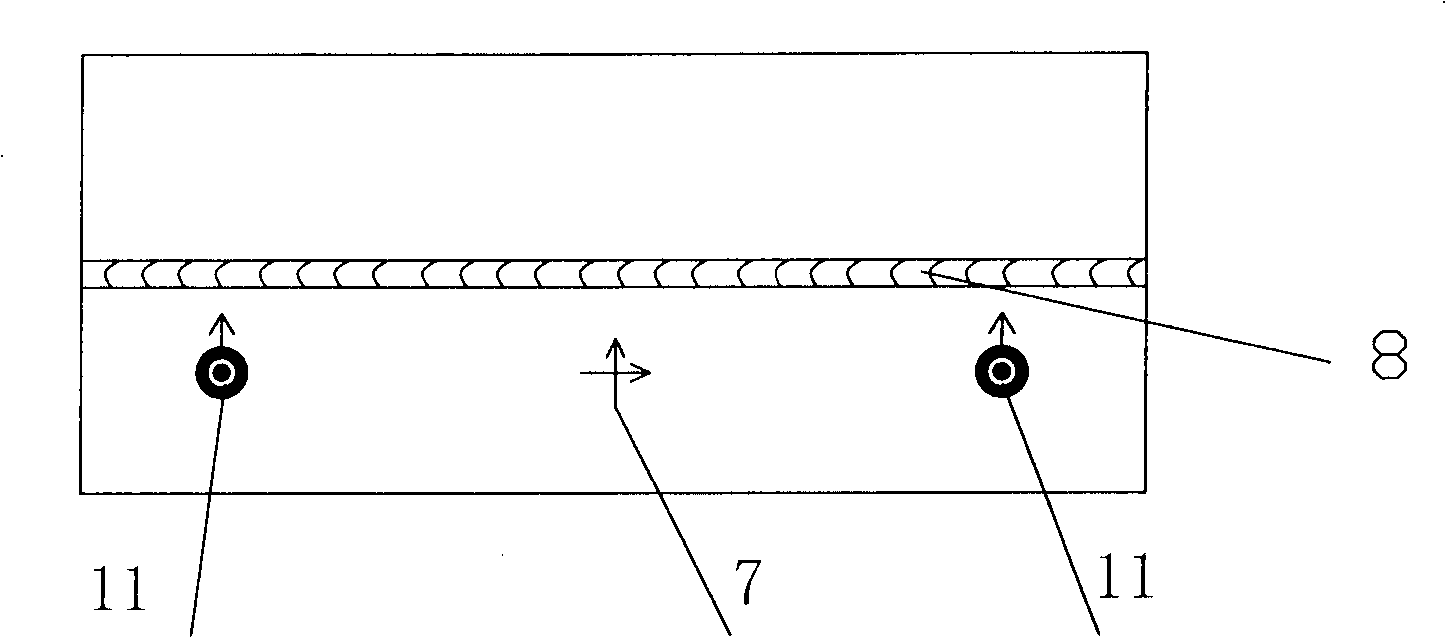

[0015] Overlapping markers; such as figure 1 As shown, the structure is composed of three concentric parts ( figure 2 ), the pointer 1 is cylindrical, the control ring 2 with the same center as the pointer 1 is ring-shaped, the pointer 1 and the control ring 2 are provided with a retaining ring 3, and the gap between the retaining ring 3 and the pointer 1 and the control ring 2 is surplus cooperation. Keep the height of the ring 3 no more than the height of the control ring. The height of the pointer 1 is greater than the height 2 of the control ring. In the vertical plane, the angle between the top A of the side AC of the pointer 1 and the bottom B of the inner ring of the control ring (that is, the angle between CA and BA) and its evaluation Theta angles are the same for K values. The pointer 1 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com