Expandable caterpillar band underpan and caterpillar band type engineering machine with the underpan

A crawler chassis and construction machinery technology, applied in the field of crawlers, can solve the problems of increased width restrictions, construction operations, and inconvenient operation of the crawler chassis, and achieve the effects of improved operational performance, high stability, and convenient conversion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

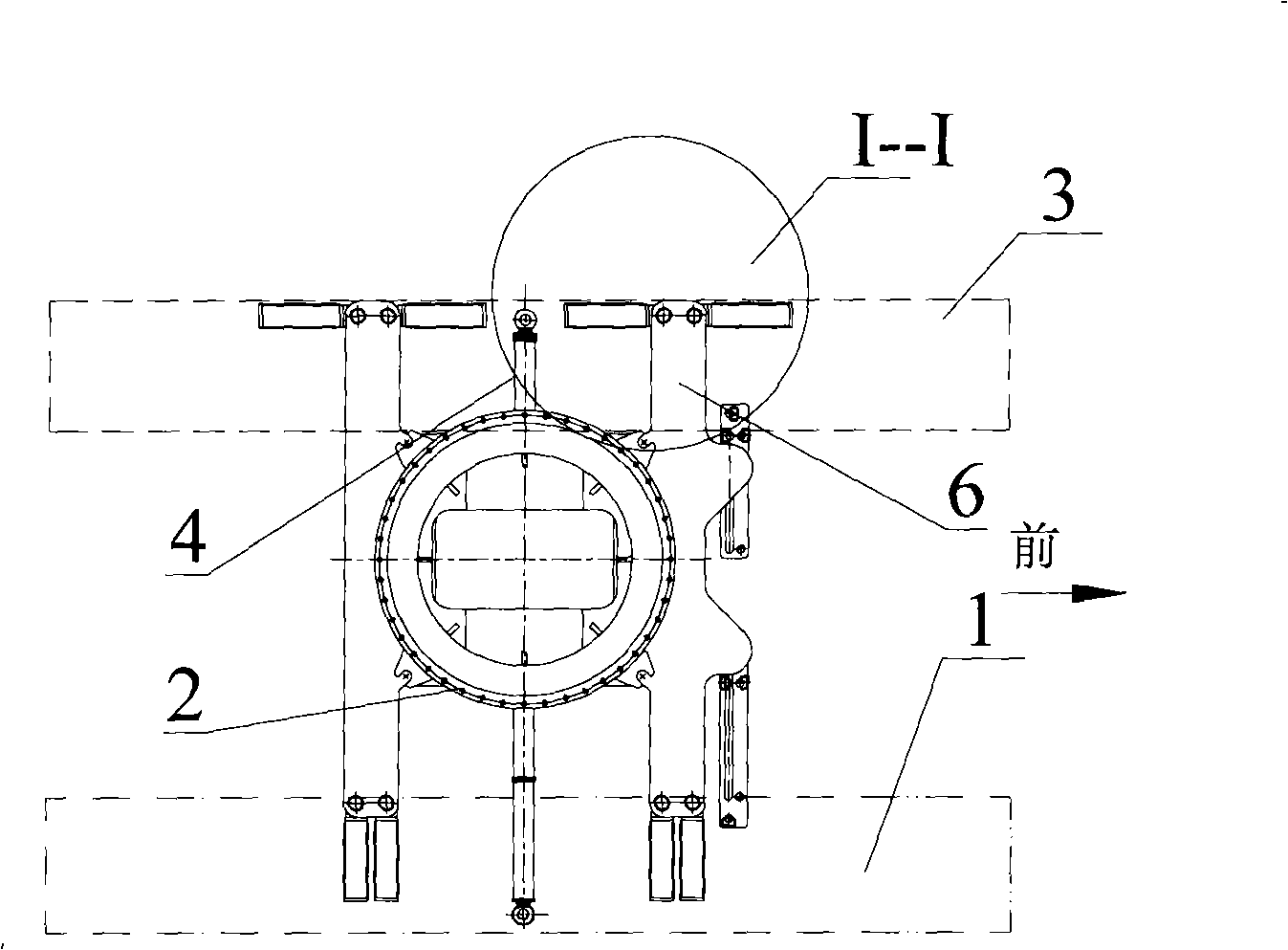

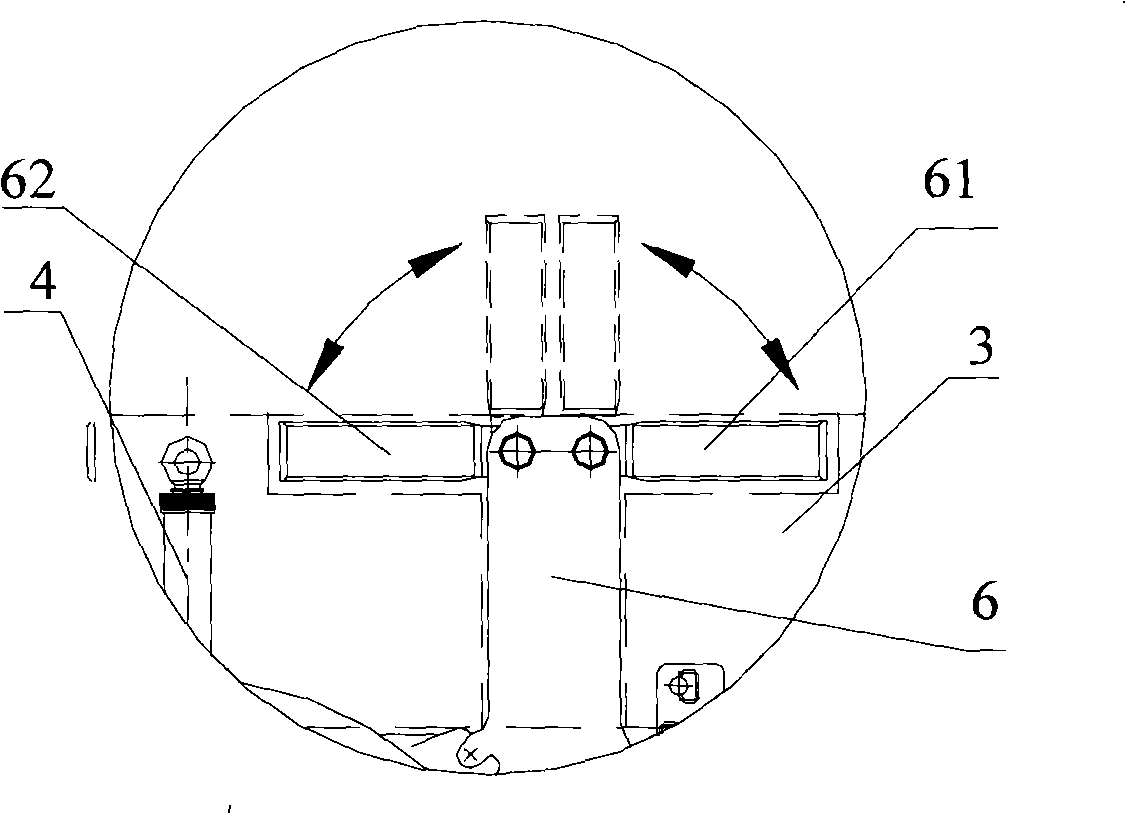

[0046] Embodiment one provides a telescopic crawler chassis of a pile driver, such as image 3 As shown, the telescopic crawler chassis includes a left crawler frame 3, a right crawler frame 1, a left telescopic oil cylinder 42, a right telescopic oil cylinder 41 and a center frame 2, and the center frame 2 is provided with a slewing bearing to install the platform of the pile driver and control parts. The left telescopic oil cylinder 42 is installed between the center frame 2 and the left crawler frame 3, and the right telescopic oil cylinder 41 is installed between the center frame 2 and the right crawler frame 1. Please combine image 3 and Figure 4 , in this embodiment, the left telescopic oil cylinder 42 and the right telescopic oil cylinder 41 are bilaterally symmetrical, and the extension line of the telescopic direction of the two passes through the center of the slewing support of the center frame 2 . The center frame 2 includes a left telescopic hole and a right ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com