Inclined pin structure

A technology of oblique pin and oblique pin rod, which is applied in the field of oblique pin structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

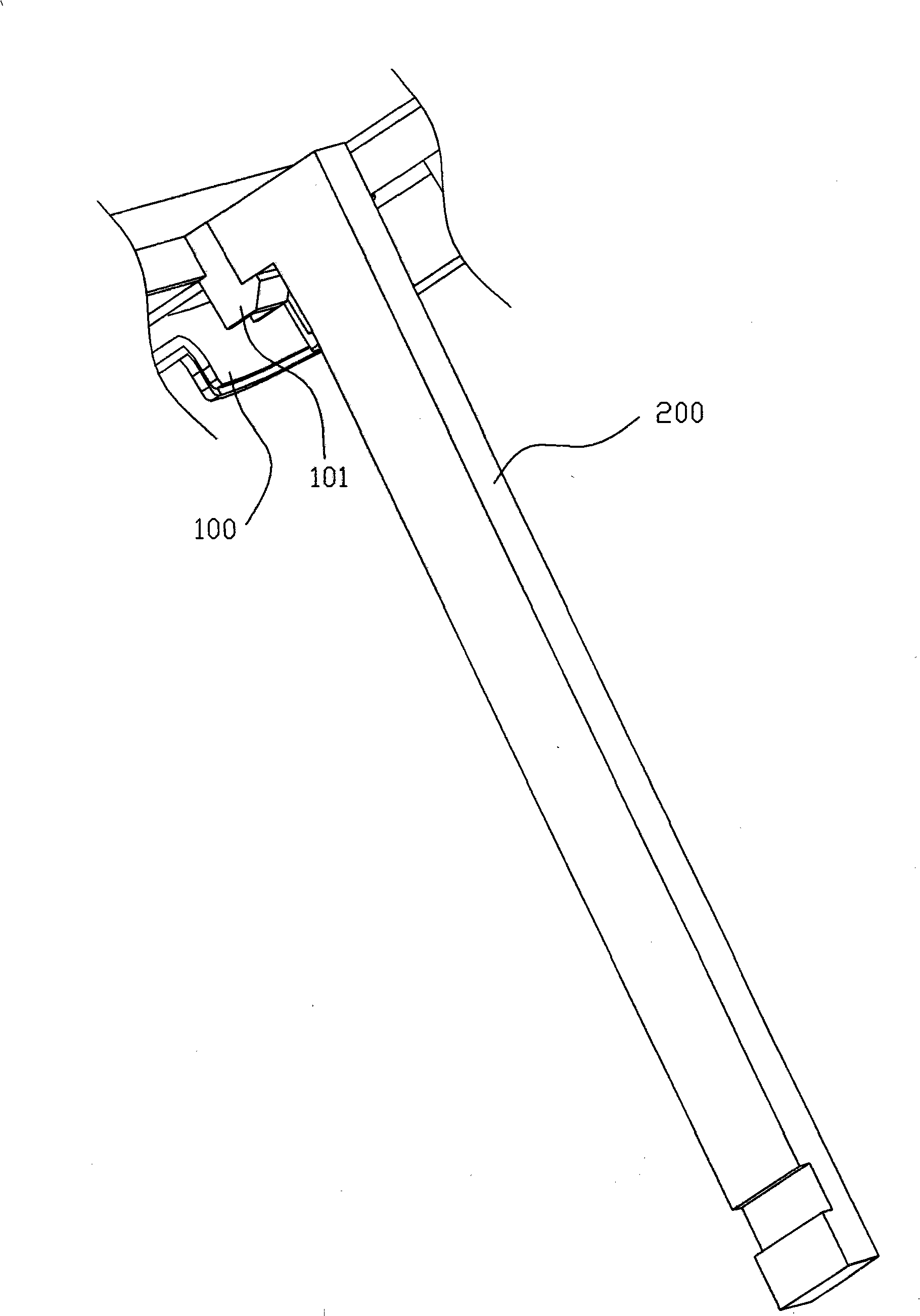

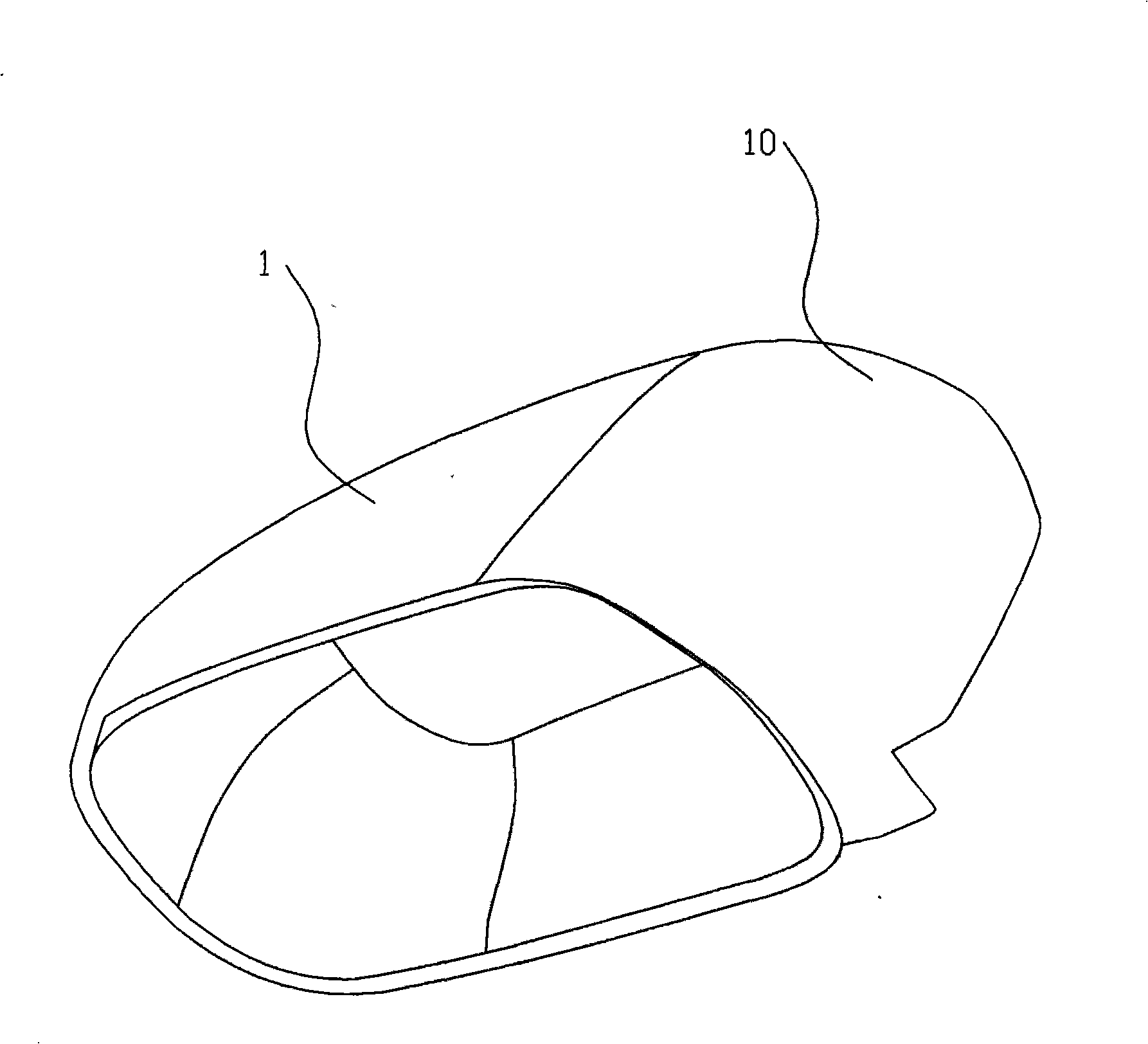

[0018] read on figure 2 , which is a three-dimensional schematic diagram of a product with a large area of barbs. Due to the large area of barbs 10 present in this product 1 . If this product 1 will be manufactured, it will be difficult to complete by adopting the current simple oblique pin molding. And a preferred embodiment of the present invention can solve the molding of this product.

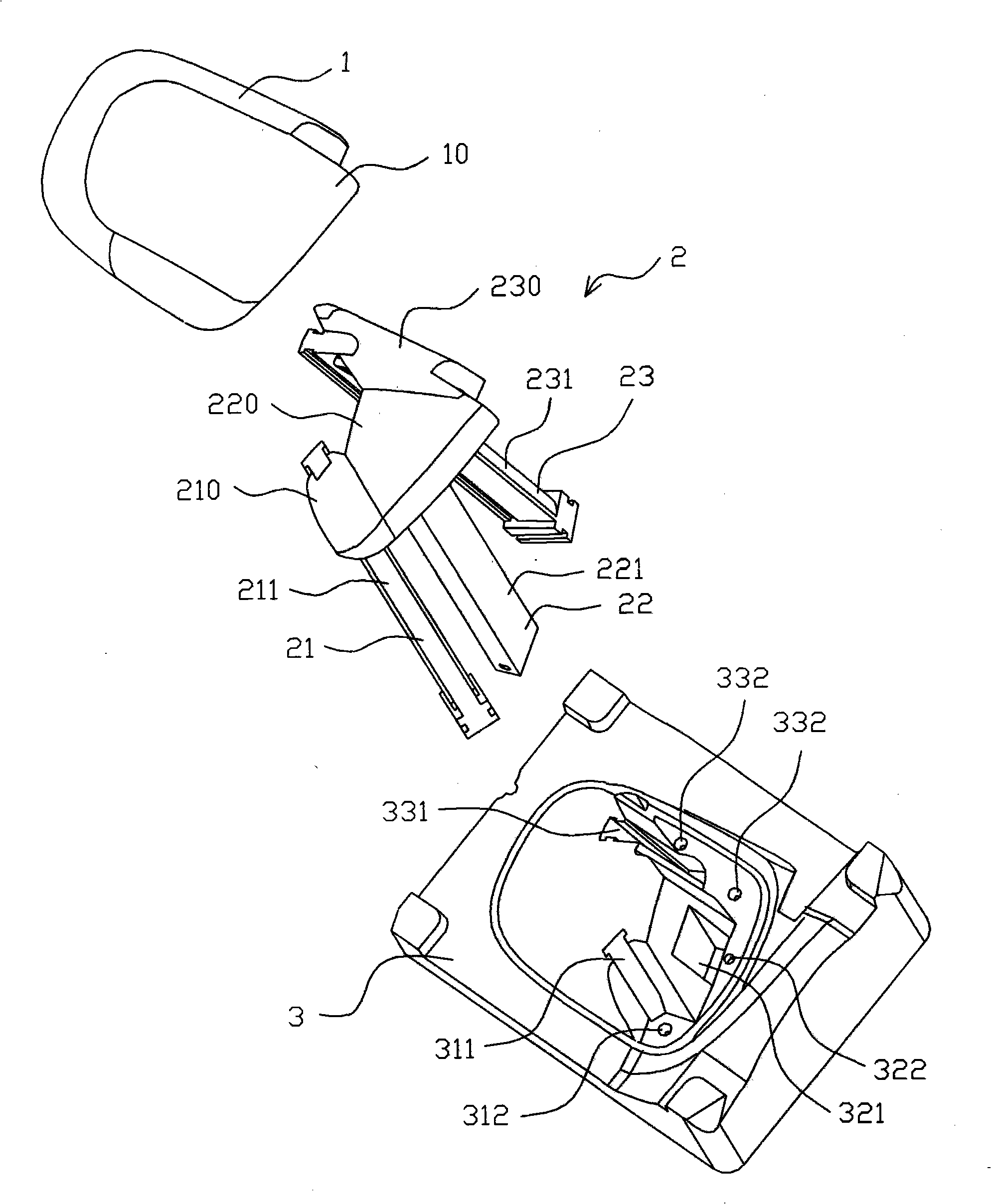

[0019] Please refer to image 3 , Figure 4 , which are respectively shown as a three-dimensional exploded view of the oblique pin structure of a preferred embodiment of the present invention and its corresponding products, and a three-dimensional exploded view of the oblique pin group of the oblique pin structure of a preferred embodiment of the present invention.

[0020] As shown in the figure, the oblique pin structure of the present invention is applied to the molding of a product 1 with a large-area barb 10 inside. In this preferred embodiment, the oblique pin structure inclu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com