Functional instant food and preparing method thereof

A functional, food technology, applied in food preparation, food science, application, etc., to achieve the effect of good taste, easy acceptance and balanced dietary nutrition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

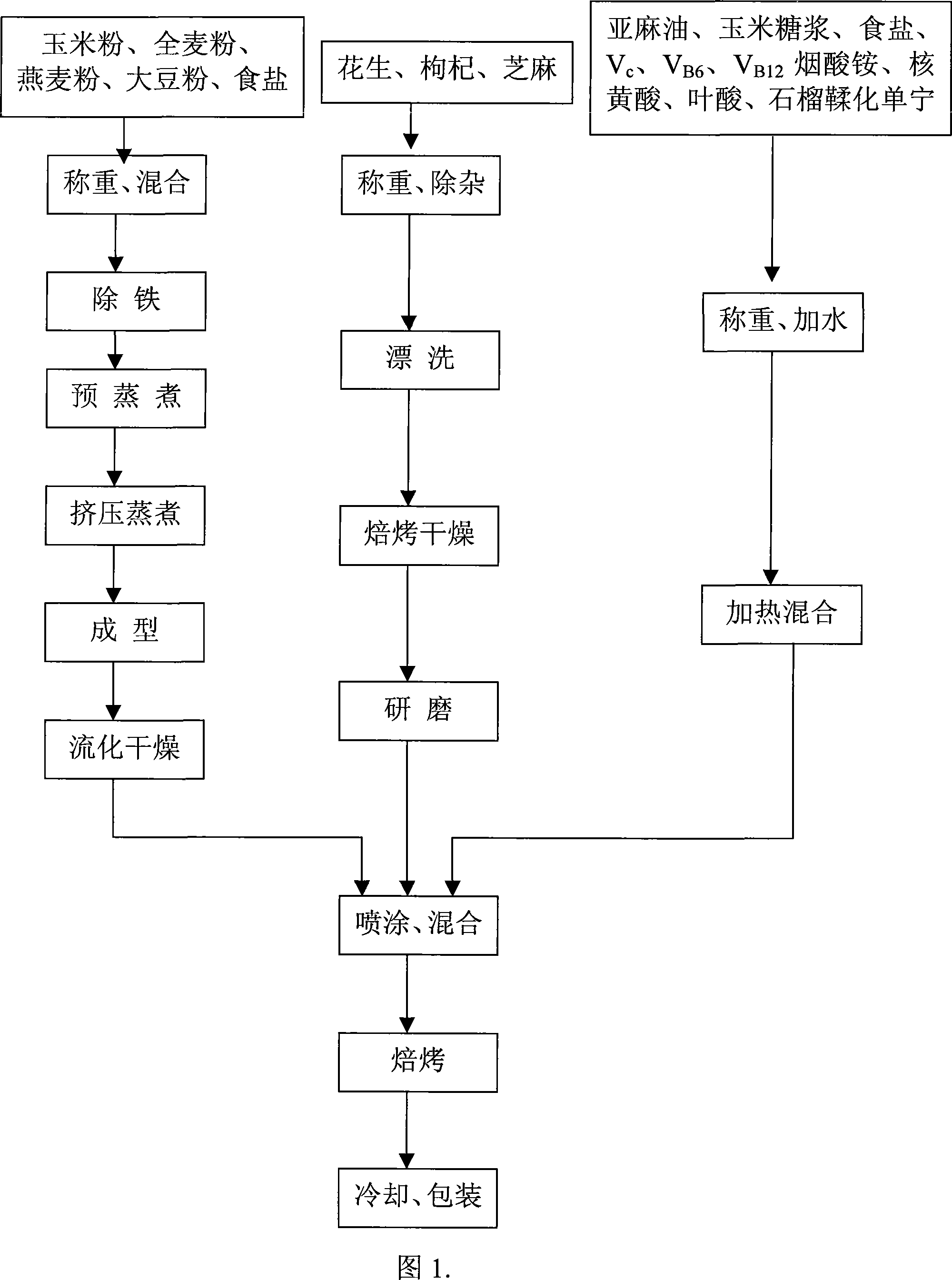

Image

Examples

Embodiment 1

[0063] 1. Processed whole wheat flour, oat flour, soybean flour and corn flour

[0064] a. Mix 50kg of whole wheat flour, 20kg of oat flour, 10kg of soybean flour, 15kg of corn flour and 0.35kg of salt evenly, remove the metal shavings from the iron remover, send them into the precooker and mix them with steam and water, so that the water content of the raw materials reaches 15% to 25%, the cooking temperature reaches 75°C, and cooking under this condition for 3 minutes;

[0065] b. Put the above-mentioned precooked raw material mixture into an extrusion cooking machine for cooking, so that the cooking temperature reaches 160°C, the pressure reaches 25Bar, and cooks for 10 seconds; this will make the starch in the raw material be completely gelatinized, and the protein will be formed from macromolecules Degraded into small molecules, fiber molecules break;

[0066] c. Exit the above-mentioned cooked raw materials from the extrusion cooking machine, the pressure and temperatur...

Embodiment 2

[0073] 1. Processed whole wheat flour, oat flour, soybean flour and corn flour

[0074] a. Mix 60kg of whole wheat flour, 25kg of oat flour, 15kg of soybean flour, 20kg of corn flour and 0.84kg of salt evenly, remove the metal filings by the iron remover, send them into the precooker and mix them with steam and water, so that the water content of the raw materials reaches 15% to 25%, the cooking temperature reaches 85°C, and cooking under this condition for 4 minutes;

[0075] b. Send the pre-cooked raw material mixture into an extrusion cooking machine for cooking, so that the cooking temperature reaches 180°C, the pressure reaches 40Bar, and cooks for 15 seconds; in this way, the starch in the raw material will be completely gelatinized, and the protein will be formed from macromolecules. Degraded into small molecules, fiber molecules break;

[0076] c. Exit the above-mentioned cooked raw materials from the extrusion cooking machine, the pressure and temperature drop rapidl...

Embodiment 3

[0083] 1. Processed whole wheat flour, oat flour, soybean flour and corn flour

[0084] a. Mix 56kg of whole wheat flour, 24kg of oat flour, 18kg of soybean flour, 13kg of corn flour and 0.42kg of salt evenly, remove the metal shavings from the iron remover, send them into the precooker and mix them with steam and water, so that the water content of the raw materials reaches 15% to 25%, the cooking temperature reaches 80°C, and cooking under this condition for 4 minutes;

[0085] b. Send the above-mentioned precooked raw material mixture into an extrusion cooking machine for cooking, so that the cooking temperature reaches 170°C, the pressure reaches 30Bar, and cooks for 12 seconds; in this way, the starch in the raw material will be completely gelatinized, and the protein will be formed from macromolecules. Degraded into small molecules, fiber molecules break;

[0086] c. Exit the above-mentioned cooked raw materials from the extrusion cooking machine, the pressure and tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com