Marine cylinder oil and method for processing same

A cylinder oil and marine technology, applied in the field of lubricating oil, can solve the problems of inability to neutralize acidic substances, cylinder liner and piston surface corrosion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

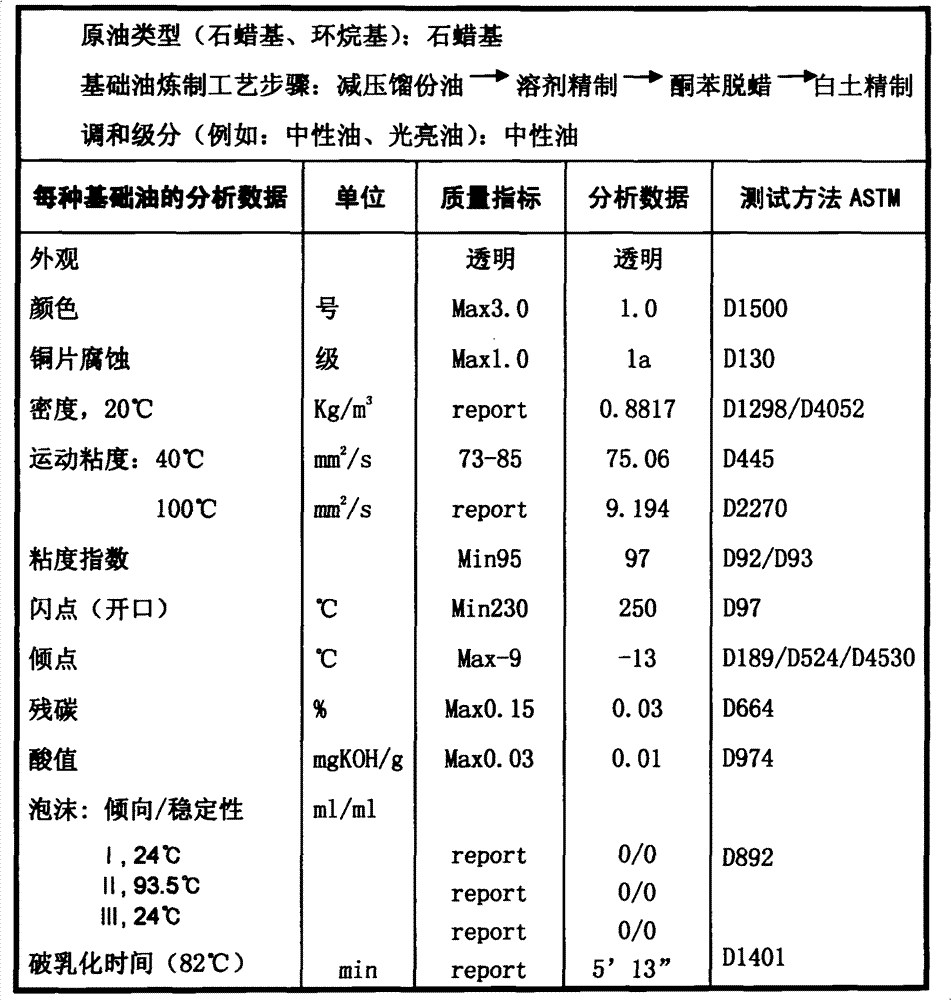

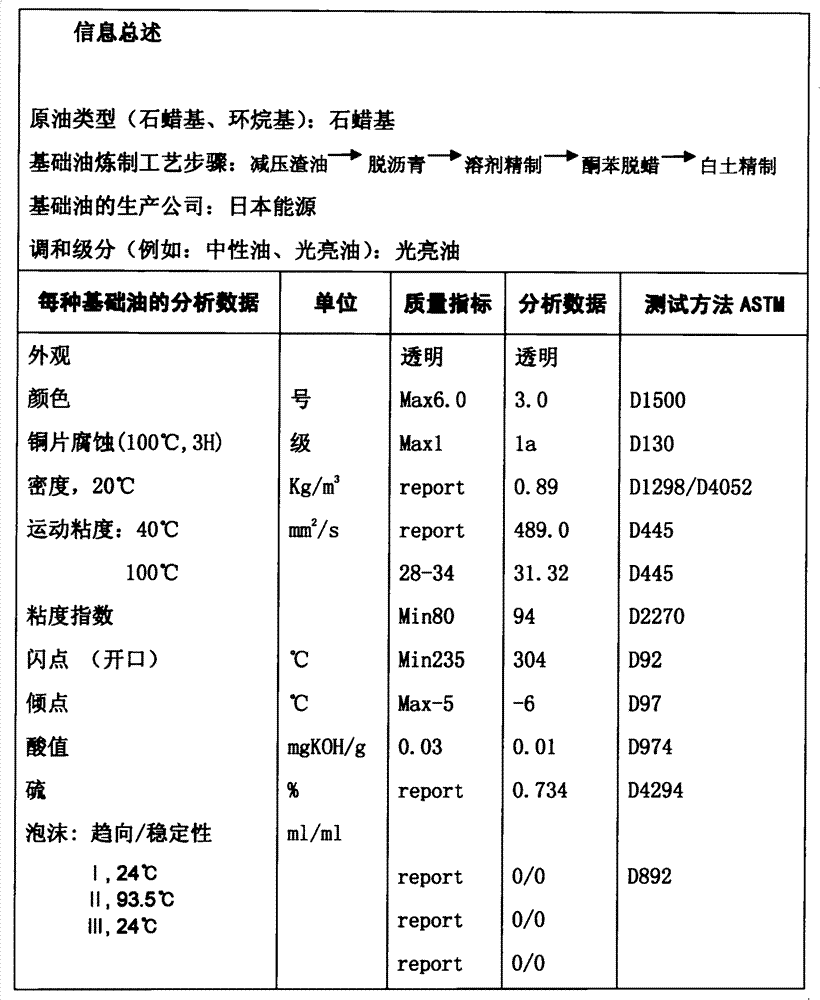

[0010] The present invention is prepared by mixing base oils with grades of 400SN and 150BS, sulfurized alkylphenate calcium, calcium naphthenate, high alkali value calcium sulfonate, ashless dispersant, and antioxidant, and the proportion of each component is: 400SN44 Parts, 11 parts of 150BS, 20 parts of sulfurized alkylphenate calcium, 13 parts of calcium naphthenate, 7 parts of high alkali value calcium sulfonate, 4 parts of ashless dispersant, 1 part of antioxidant, its performance parameters: at 100 ℃ condition, 16.3mm 2 / s≤kinematic viscosity2 / s, pour point≤-5°C, flash point≥210°C, total base number≥98mgKOH / g, viscosity index≥70, moisture≤0.06%, under the condition of 100°C, 3h, copper sheet corrosion≤1 grade.

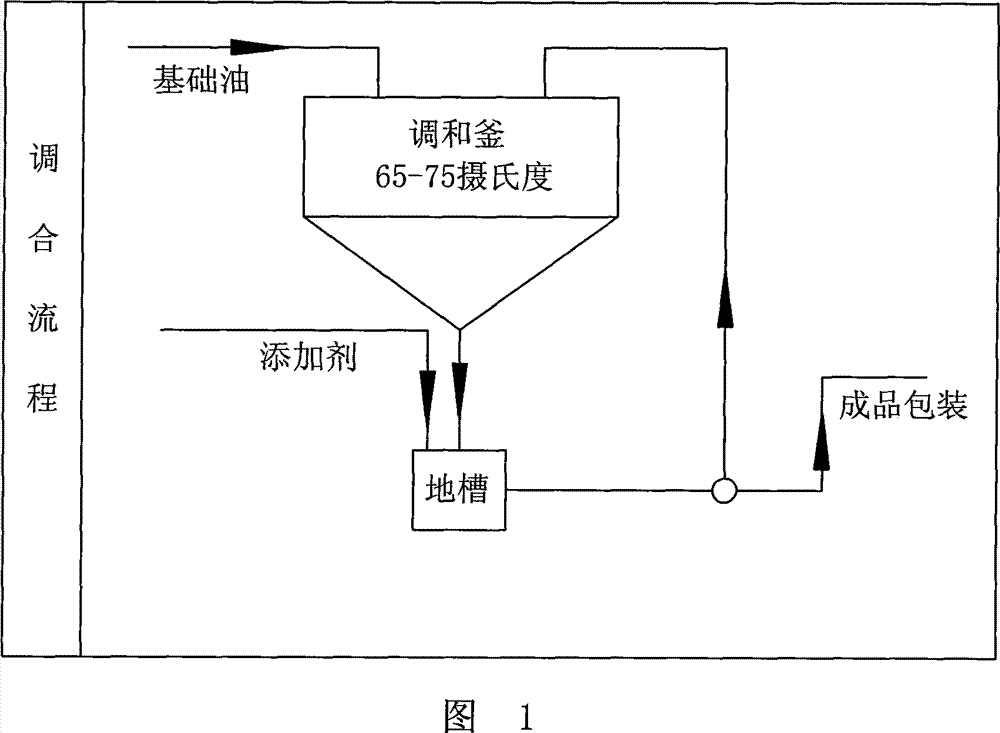

[0011] The technical process of the present invention is described below in conjunction with the accompanying drawings: put the correctly measured base oils of grade 400SN and grade 150BS into the blending tank, and heat up to 70±5°C, the optimum temperature is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

| viscosity index | aaaaa | aaaaa |

| viscosity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com