Explosion-resisting method and device for electro-galvanizing zinc dissolving station

An electro-galvanizing and anti-explosion technology, applied in the electrolysis process, electrolysis components, cells, etc., can solve the problems of easy to cause errors, no hydrogen, no control and protection system, etc., to avoid errors or negligence, and eliminate the effect of hydrogen overflow

Active Publication Date: 2008-03-26

BAOSHAN IRON & STEEL CO LTD

View PDF0 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] The electro-galvanizing zinc-dissolving station in the currently used electro-galvanizing unit has the following defects: there is no material level display device, and it is completely observed manually, which is very easy to cause errors;

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

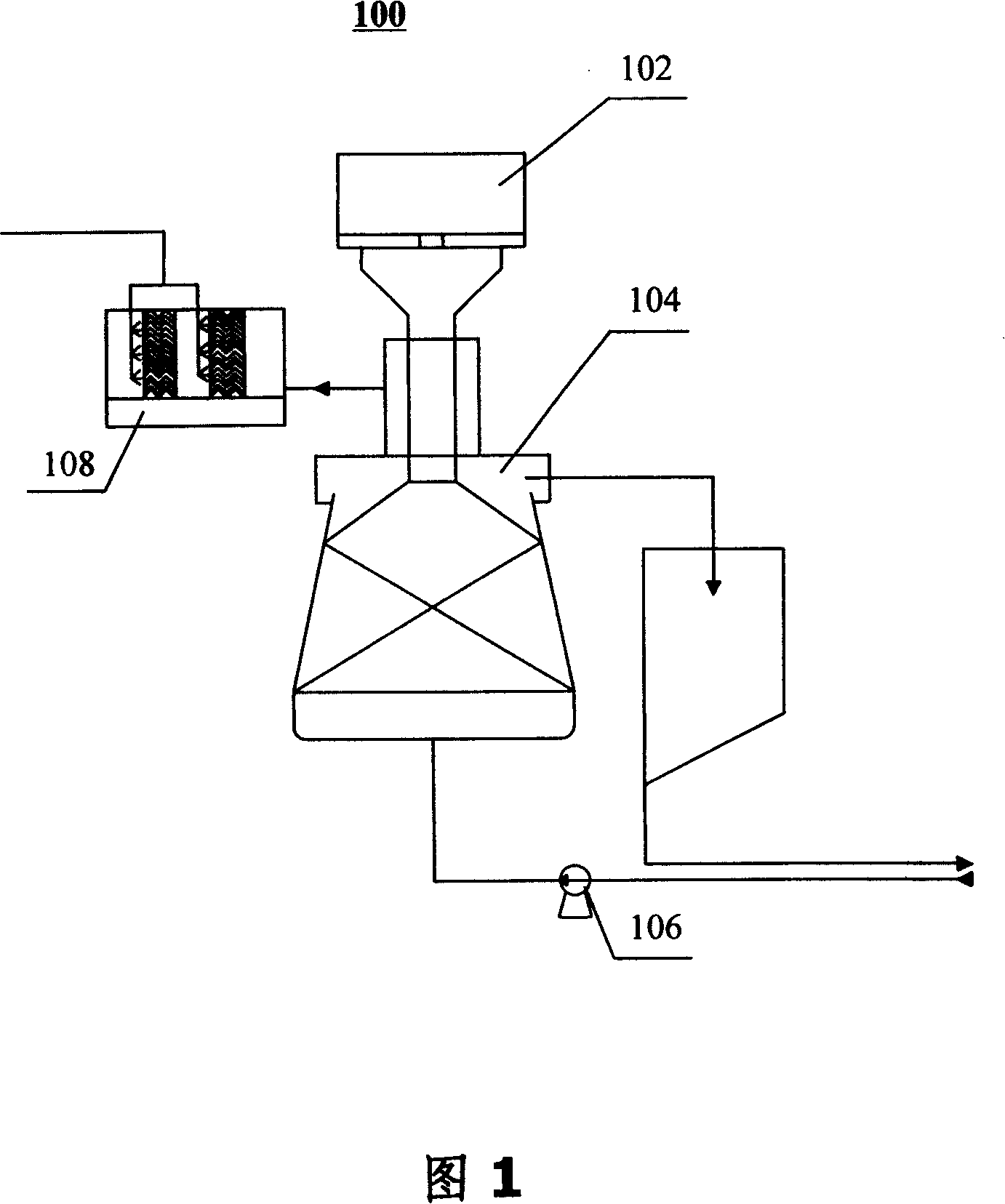

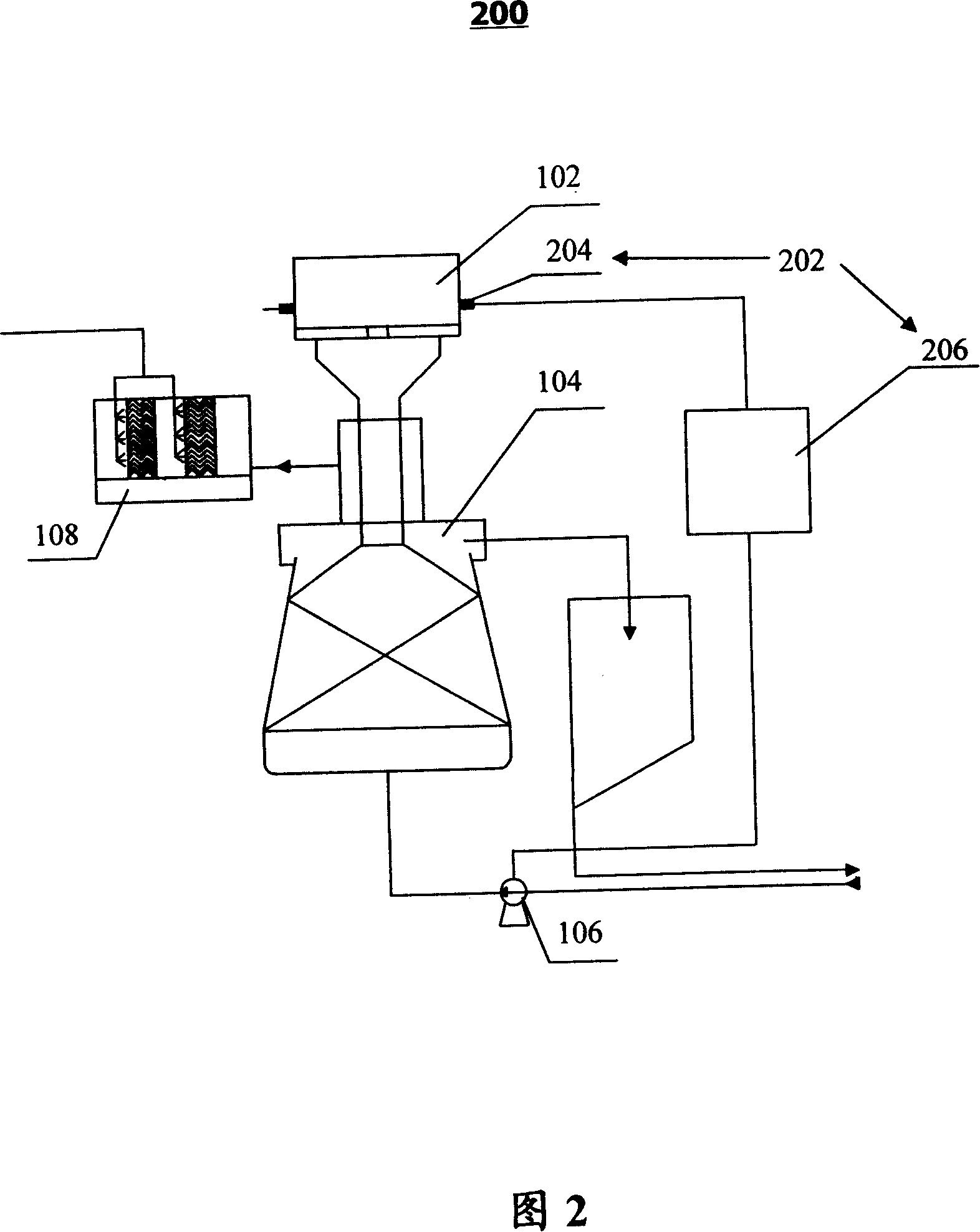

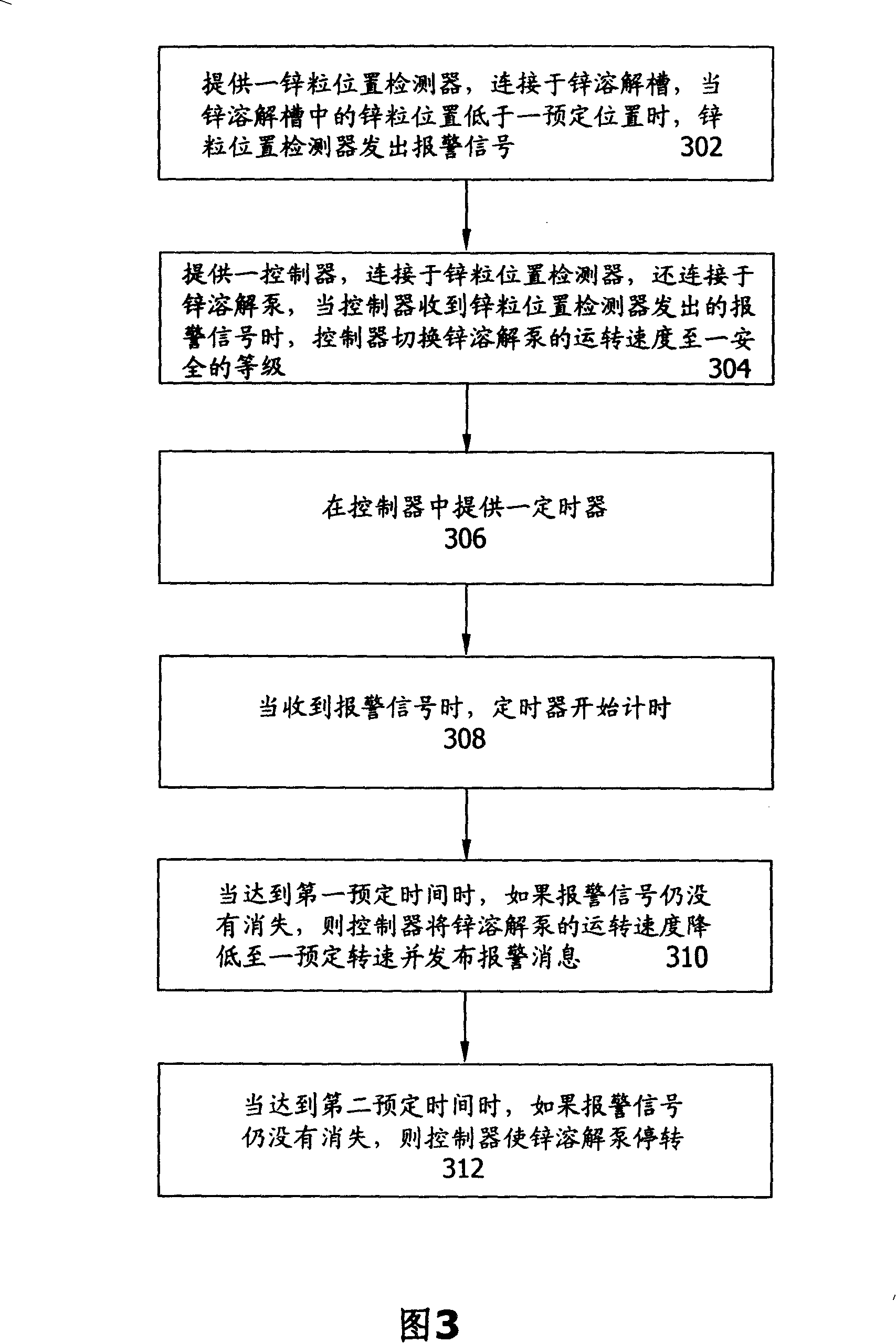

The present invention reveals explosion preventing method and apparatus for electroplated zinc dissolving station. The explosion preventing apparatus connected to the zinc dissolving tank and zinc dissolving pump in electroplated zinc dissolving station includes one zinc grain position detector to send out one warning signal in case of zinc grain position lower than certain set position; and one controller connected to the zinc grain position detector to change the operation rate of the zinc dissolving pump to one safe value when the zinc grain position detector sends out warning signal. The present invention can prevent accident caused by hydrogen overflow actively.

Description

technical field [0001] The invention relates to the safety protection technology of electro-galvanizing equipment, more specifically, relates to an explosion-proof method and device of an electro-galvanizing and dissolving station. Background technique [0002] In the current continuous electrogalvanizing unit using the gravity electroplating process, the supplement of zinc ions in the electroplating process is realized by continuously dissolving zinc particles through the zinc dissolving station system. During the process of dissolving zinc in the zinc dissolving station, a large amount of hydrogen gas will be generated. Although the exhaust gas exhaust device continuously pumps the hydrogen-containing waste gas into the atmosphere for release, the hydrogen gas in the zinc dissolving tank will still maintain a certain pressure. Once the zinc particles are dissolved and are not added in time, hydrogen gas will overflow from the mouth of the zinc feeding pipe. When the concen...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C25D21/14C25D3/22

Inventor 许玉华黄胜标杨国良唐文元胡鸿雁

Owner BAOSHAN IRON & STEEL CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com