Hammer wheel for float mill

A hammer wheel and grinding technology, which is applied in grain processing and other directions, can solve the problems of increasing ineffective power, increased wear of the ring lining plate 1 and eccentric shaft 4, and inertial imbalance, so as to shorten the time and simplify the installation and disassembly process. handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

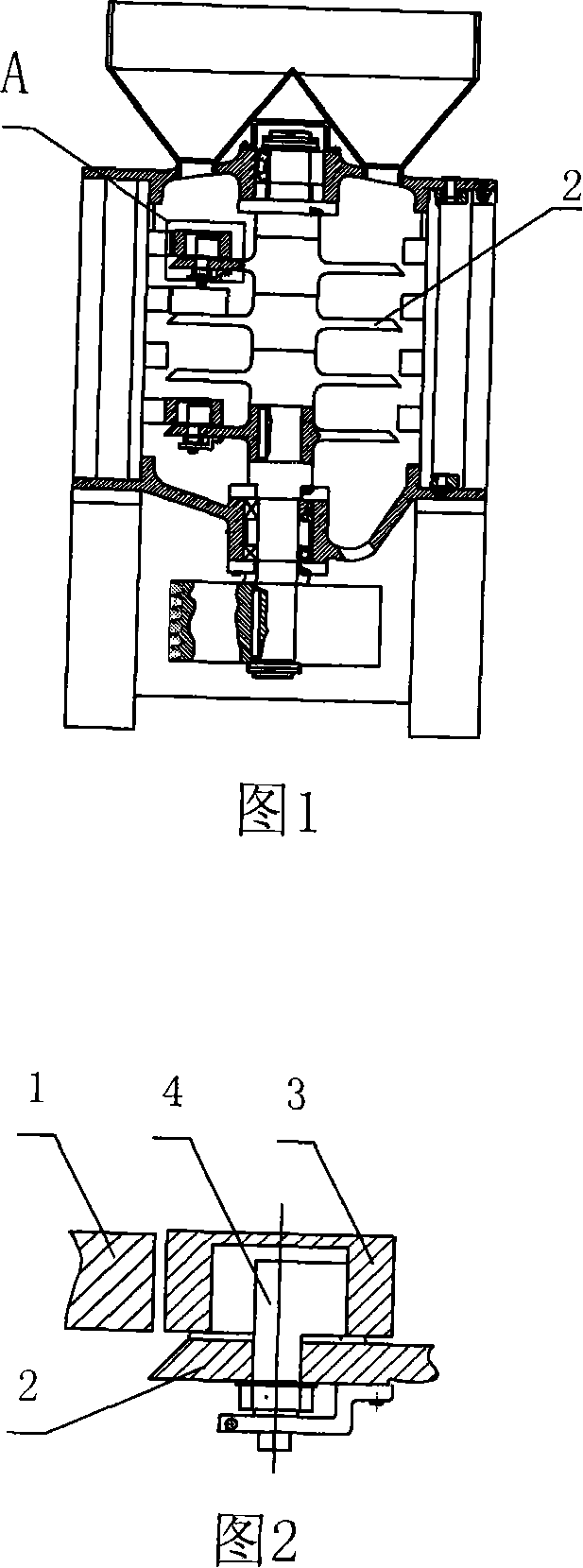

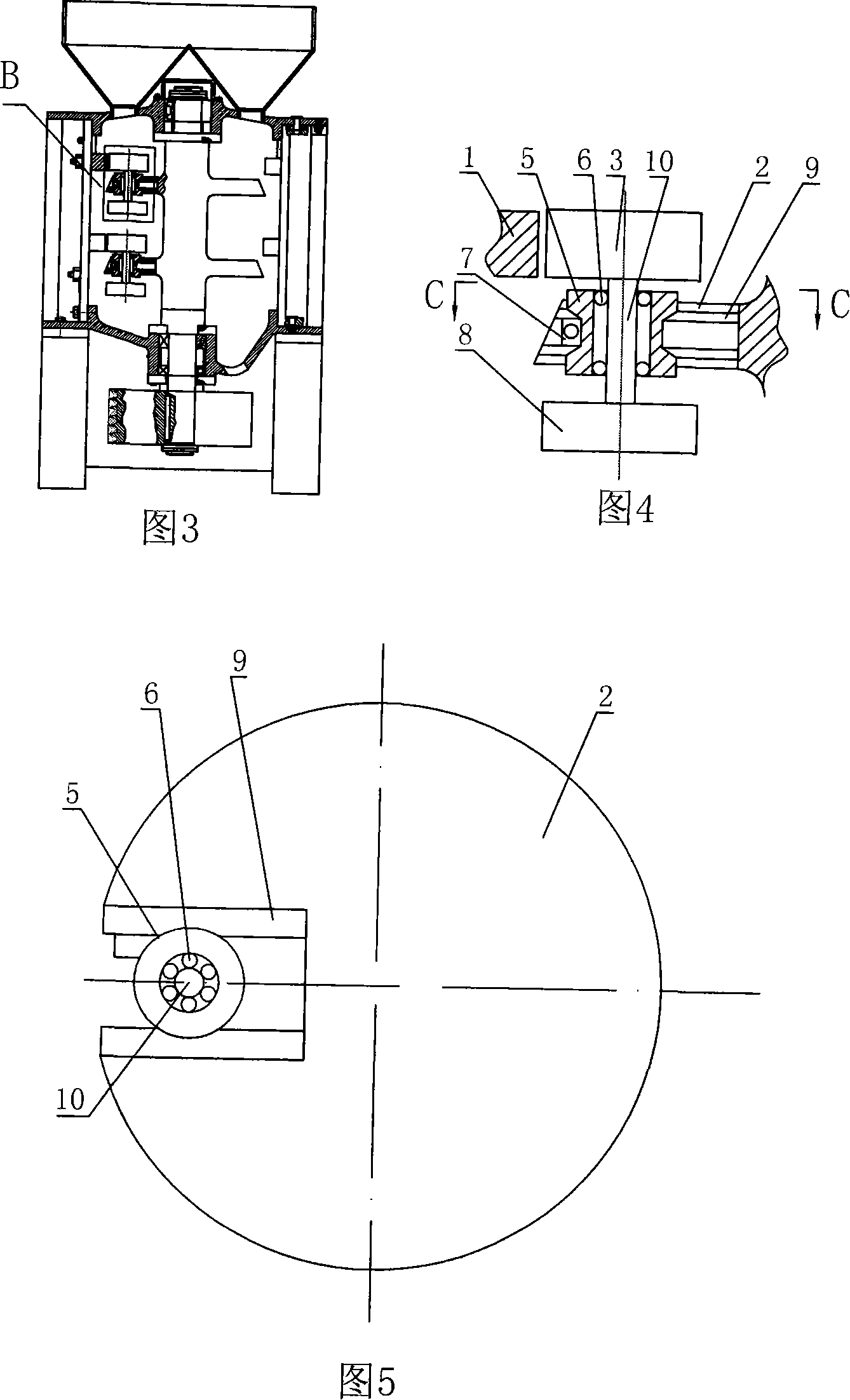

[0019] A hammer wheel of a floating mill, as shown in Figure 3-5. The hammer wheel is installed on the turntable 2, corresponding to the ring liner 1. There are gaps distributed on the corresponding positions of the turntable 2, the two radial sides of the gap are equipped with rails 2, the hammer wheel assembly is installed on the rail 9 and fixed in the gap by the pressure plate 7, the outer edge of the roller 5 matches the shape of the rail 9, Bearing 6 is equipped with in roller 5 inner holes, and tup 3, flywheel 8 are installed on the bearing 6 of roller 5 inner holes by hammer shaft 10.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com