Precision assembling mechanical arm with parallel structure six-dimension force sensing

A six-dimensional force sensor and manipulator technology, which is applied in the field of manipulator devices and precision assembly manipulators, can solve the problems of only two and cannot realize arbitrary adjustment of posture, so as to improve production efficiency and quality, reduce labor intensity of workers, and achieve high rigidity. Assembly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

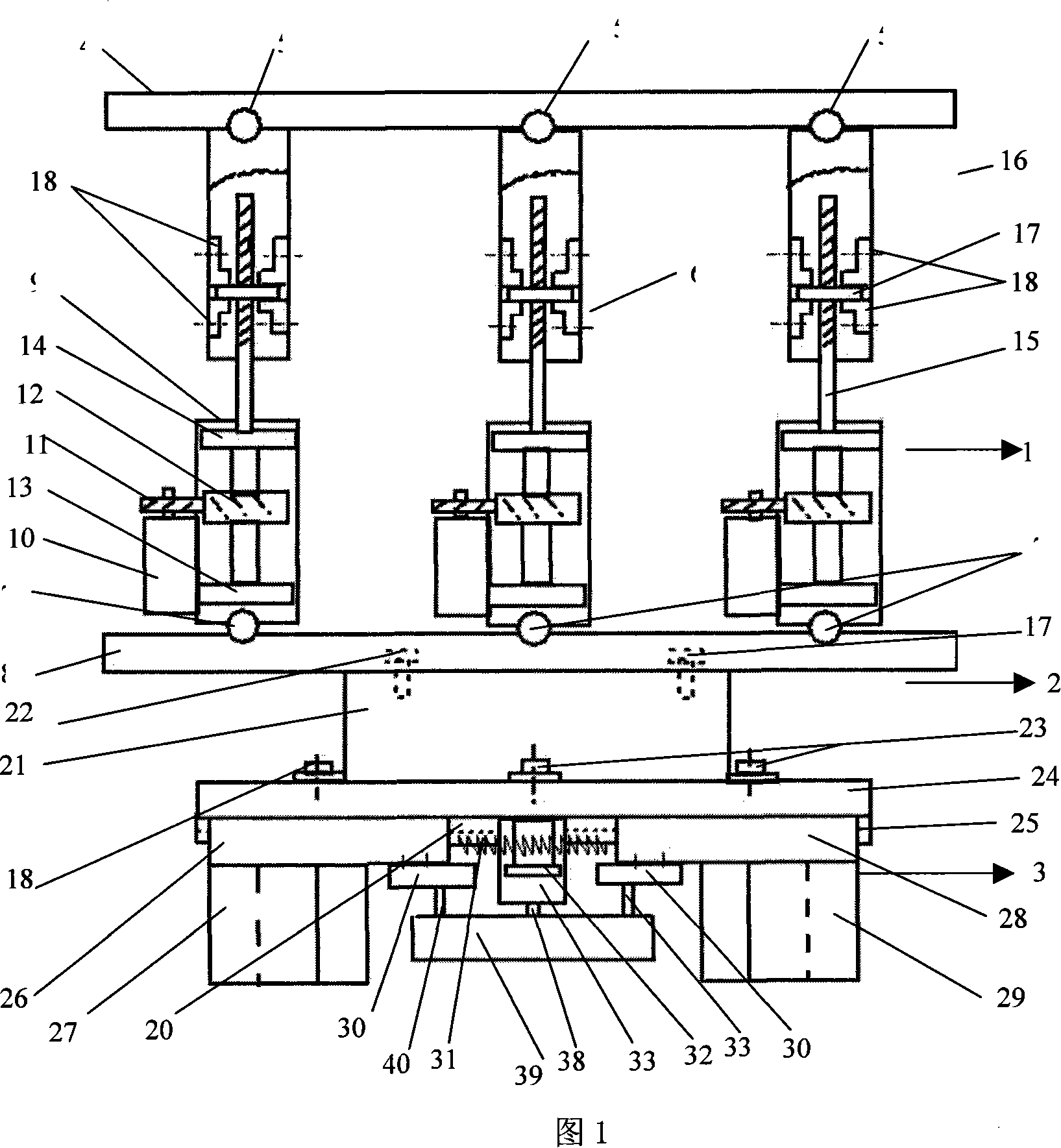

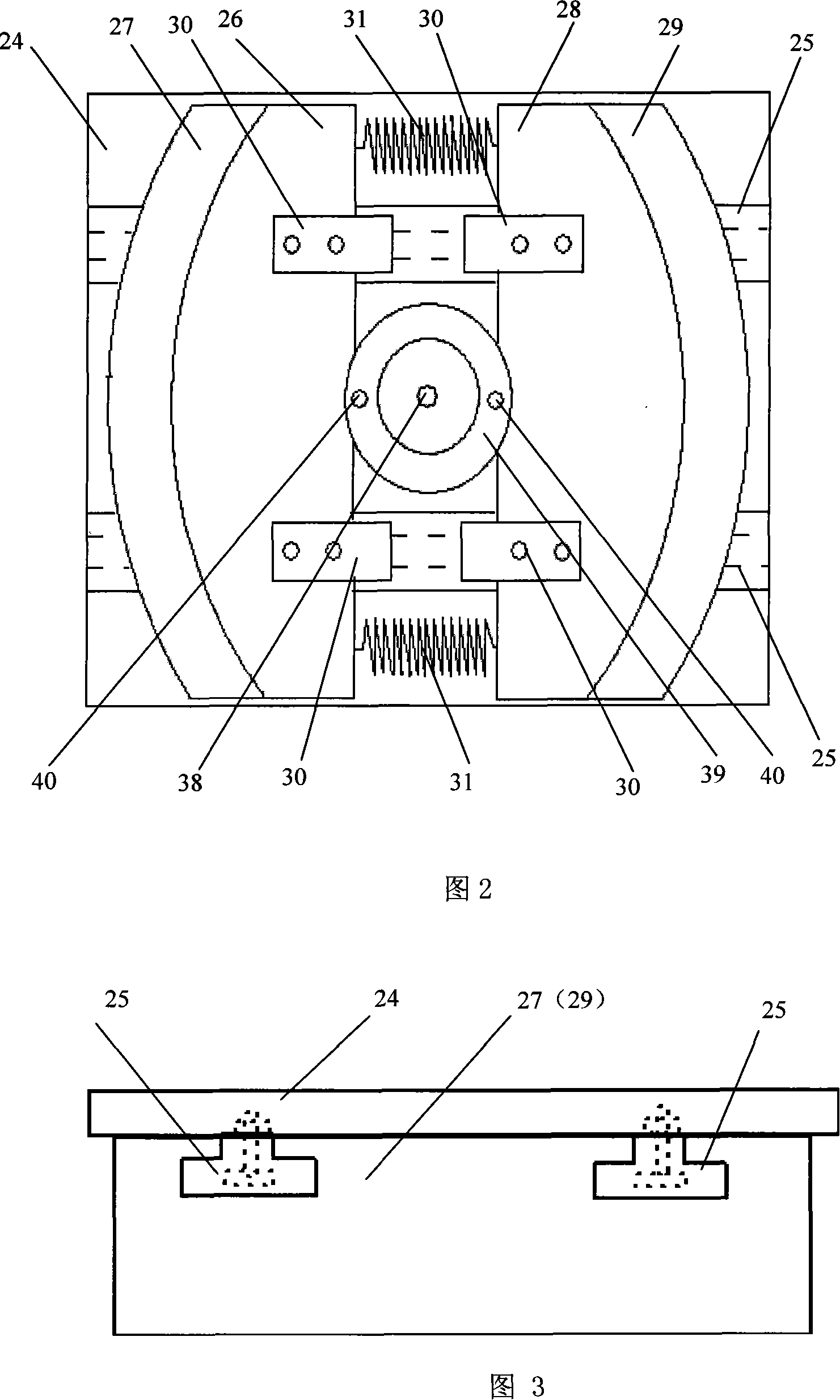

[0019] The embodiments of the present invention are described in detail below in conjunction with the accompanying drawings: the present embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and processes are provided, but the protection scope of the present invention is not limited to the following implementations example.

[0020] The connection relationship of each part is as follows:

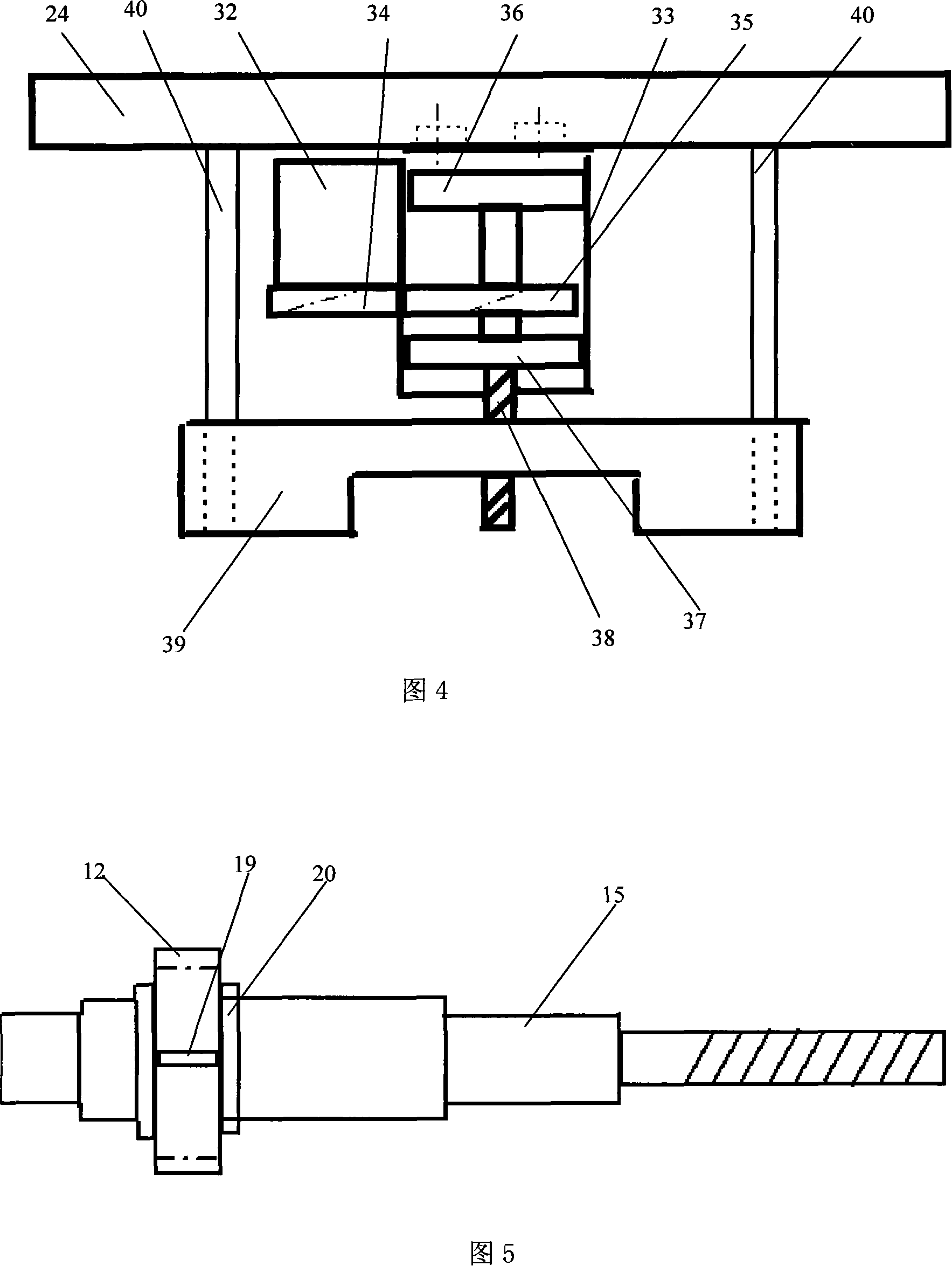

[0021] As shown in FIG. 1 and FIG. 5 , the lower sleeve 9 is arranged on the lower platform 8 through the ball hinge 7 , and the upper sleeve 16 is arranged on the upper platform 4 through the ball hinge 5 . The motor 10 is fixed on the lower sleeve 9 , and the first gear 11 is arranged on the output shaft of the motor 10 and meshes with the second gear 12 . The second gear 12 is arranged on the rotating shaft 15 by the first flat key 19 and the first fastening nut 20, and the rotating shaft 15 is arranged on the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com