Low-temperature demulsifying agent and preparation method thereof

A demulsifier and low-temperature technology, which is applied in the field of oilfield chemistry, can solve problems such as inapplicability, poor adaptability of crude oil products, demulsifier flocculation ability, coalescence ability and dehydration effect are not ideal, so as to reduce production costs and save energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

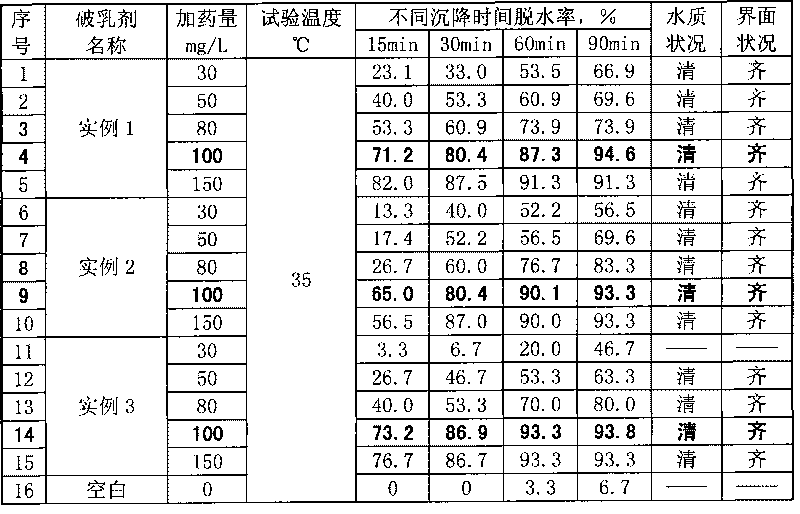

Examples

Embodiment 1

[0018] One, the preparation of intermediate PEA

[0019] First, add 1 mol of phenol and 3 mol of tetraethylenepentamine into the reaction kettle to start stirring, heat up to 140°C, evacuate and fill with nitrogen, then slowly add 3 mol of formaldehyde dropwise, the reaction pressure is 0.3-0.45MPa, and the reaction temperature is 140±5°C ;After 2 hours of reaction, the temperature dropped to 120°C, and then slowly added dropwise 0.035mol of toluene, the reaction pressure was 0.2-0.35MPa, and the reaction temperature was 120±5°C, and the reaction was balanced for 1 hour. After the pressure in the reactor returned to zero, the temperature was lowered to obtain the intermediate PEA.

[0020] 2. Preparation of dry agent

[0021] First, add 35% intermediate PEA and 3.0% sodium hydroxide to the reaction kettle, start stirring, heat up to 135°C, evacuate, fill with nitrogen, and then slowly add 27% propylene oxide dropwise. The reaction pressure is 0.2~0.25MPa , Reaction temperatu...

Embodiment 2

[0025] One, the preparation of intermediate PEA

[0026] First, add 1.2 mol of phenol and 2.6 mol of tetraethylenepentamine into the reaction kettle to start stirring, heat up to 140°C, evacuate and fill with nitrogen, then slowly add 2.3 mol of formaldehyde dropwise, the reaction pressure is 0.3-0.45MPa, and the reaction temperature is 140°C. ±5°C; after 2 hours of reaction, the temperature drops to 120°C, then slowly add 0.04mol of toluene dropwise, the reaction pressure is 0.2-0.35MPa, the reaction temperature is 120±5°C, and the reaction is balanced for 1 hour. After the pressure in the reactor returns to zero, the temperature is lowered. The intermediate PEA is obtained.

[0027] 2. Preparation of dry agent

[0028] First, add 24% intermediate PEA and 1.8% sodium hydroxide to the reaction kettle, start stirring, heat up to 135°C, evacuate, fill with nitrogen, and then slowly add 33% propylene oxide dropwise. The reaction pressure is 0.2-0.25MPa , Reaction temperature 13...

Embodiment 3

[0032] One, the preparation of intermediate PEA

[0033] First, add 1.4 mol of phenol and 3.3 mol of tetraethylenepentamine to the reaction kettle to start stirring, heat up to 140°C, evacuate and fill with nitrogen, then slowly add 3.8 mol of formaldehyde dropwise, the reaction pressure is 0.3-0.45MPa, and the reaction temperature is 140°C. ±5°C; After 2 hours of reaction, the temperature drops to 120°C, then slowly add 0.045mol of toluene dropwise, the reaction pressure is 0.2-0.35MPa, the reaction temperature is 120±5°C, and the reaction is balanced for 1 hour. After the pressure in the reactor returns to zero, cool down. The intermediate PEA is obtained.

[0034] 2. Preparation of dry agent

[0035] First, add 38% intermediate PEA and 3.3% sodium hydroxide to the reaction kettle, start stirring, heat up to 135°C, evacuate, fill with nitrogen, and then slowly add 25.7% propylene oxide dropwise. The reaction pressure is 0.2~0.25MPa , Reaction temperature 130±5℃; then slowl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com