Preparation method of ultra low-sulfur oil

An ultra-low-sulfur gasoline technology, applied in the direction of refining with oxygen-containing compounds, can solve the problems of reducing operating costs, disadvantages, and oil products that cannot meet the requirements of ultra-low-sulfur gasoline, and achieve the effect of reducing production costs and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

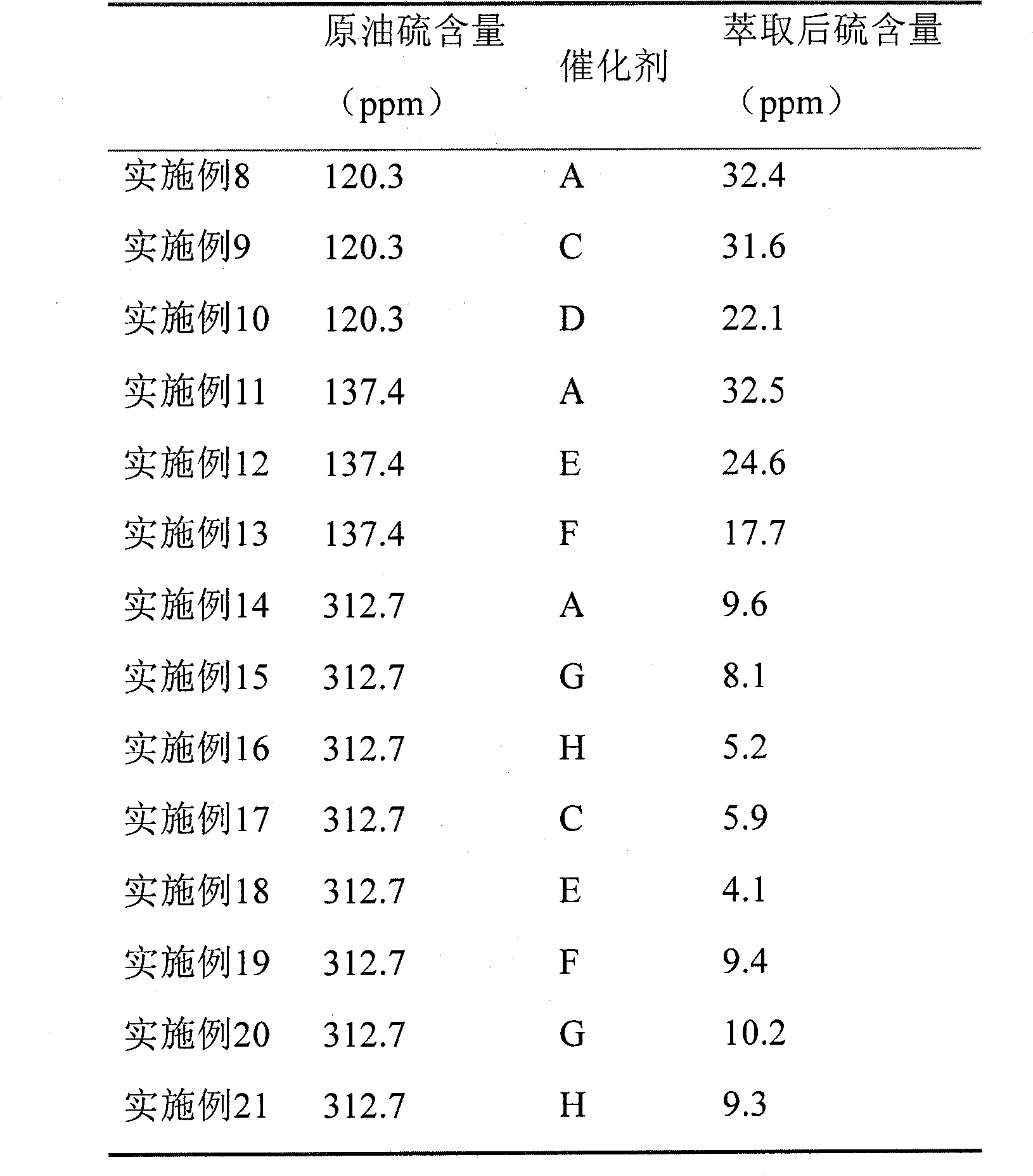

Examples

Embodiment 1

[0023] Preparation of catalyst:

[0024] As an illustrative example, the catalyst [(C 18 H 37 )N + (CH 3 ) 3 ][PW 3 O q ] can be prepared as follows: 1.87g of tungstic acid is weighed and suspended in 10.0ml of hydrogen peroxide, vigorously stirred in an oil bath at 60°C for 30min, dissolved, and cooled to room temperature; 0.39g of sodium dihydrogen phosphate is weighed and dissolved in 5ml of water, Stir at room temperature for 5 min, add it to the hydrogen peroxide solution of tungstic acid, stir to adjust pH=2-3; then take 2.6 g of quaternary ammonium salt octadecyl trimethyl ammonium chloride and dissolve it in 10 ml of absolute ethanol, Drop into the above mixed solution and stir vigorously at the same time, a white precipitate is formed immediately, the dropwise addition time is 1-2h, and the stirring is continued for 3-4h; finally, it is filtered, washed with ionized water, and vacuum-dried to obtain a white solid catalyst. called catalyst A.

Embodiment 2

[0026] The same as in Example 1, except that the ratio of phosphorus to tungsten is 1:1, which is called catalyst C.

Embodiment 3

[0028] The same as in Example 1, except that the ratio of phosphorus to tungsten is 1:5, which is called catalyst D.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com