Automatic bearing cleaning machine

An automatic cleaning machine and bearing technology, applied in the direction of conveyors, conveyor objects, mechanical conveyors, etc., can solve problems such as the inability to form automatic cleaning bearings, and achieve the effects of avoiding bumps, improving utilization, and reducing labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

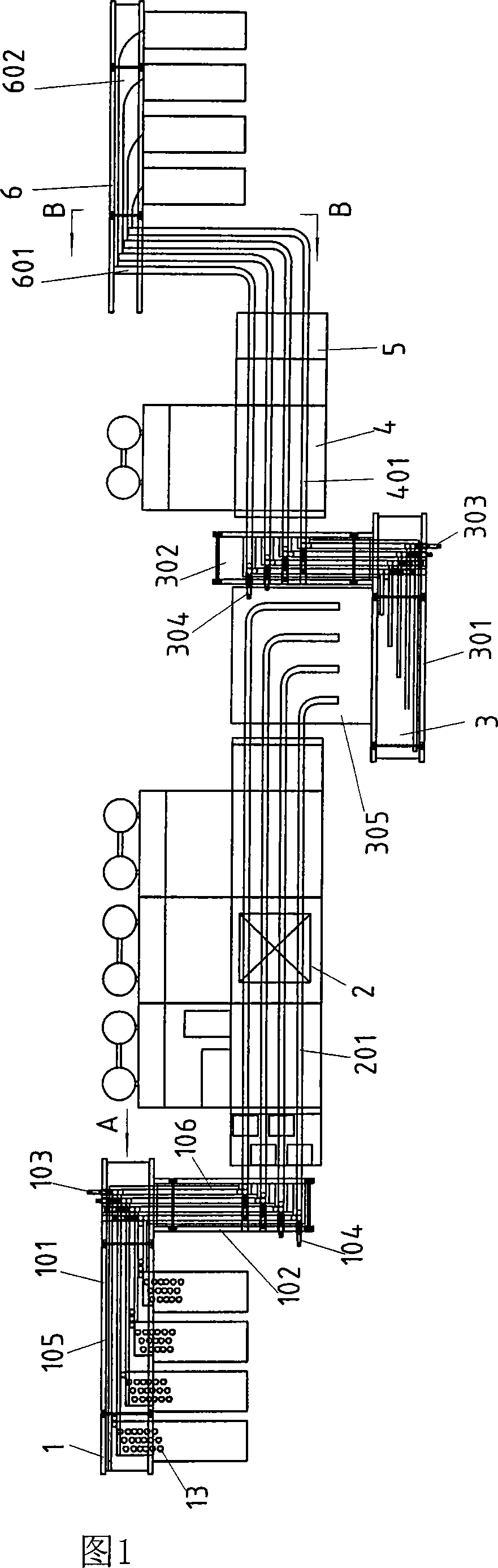

[0020] As shown in Fig. 1, the present invention comprises feeding conveying device 1, ultrasonic coarse cleaning machine 2, ultrasonic fine cleaning machine 4, dryer 5, wherein, ultrasonic rough cleaning machine 2, ultrasonic fine cleaning machine 4, dryer 5 Adopt commercially available commodity, be prior art. At least two feed rails can be installed in each device of the present invention, four feed rails are installed in the embodiment shown in Figure 1, and other numbers of feed rails can also be installed according to actual needs.

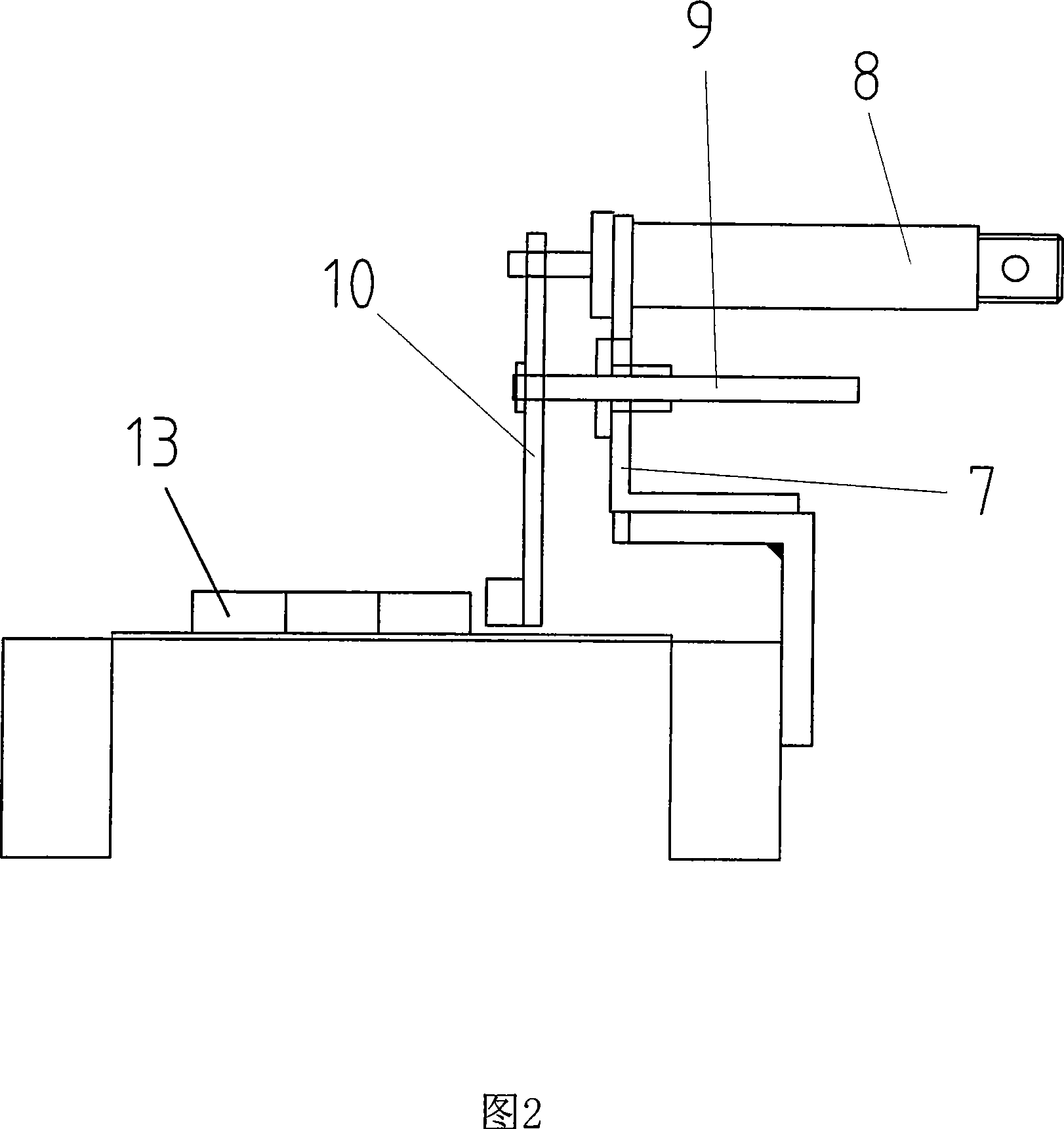

[0021] Feeding conveying device 1 is made up of the first feeding channel 101, the second feeding channel 102, the first pushing device 103, the second pushing device 104, in the embodiment shown in Fig. 1, the first feeding channel 101, the second Feed channel 102 is respectively wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com