Method for realizing the assembly of shaft hole having high-precision by using robot having low precision

A robot and high-precision technology, applied in the field of robots, can solve problems such as difficult high-precision assembly, and achieve the effect of improving the scope of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

Specific Example 1

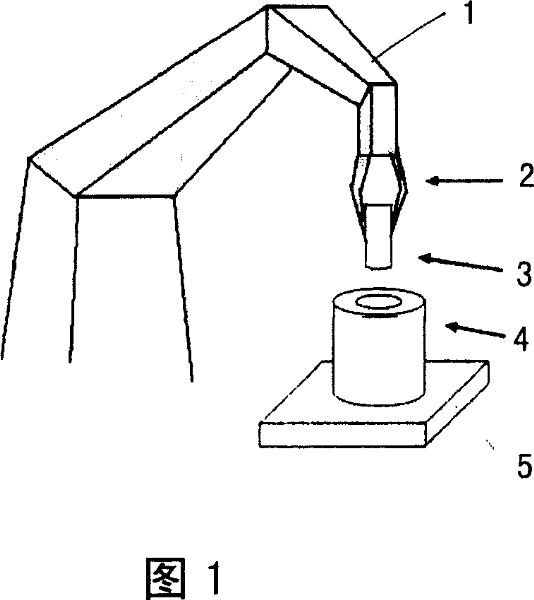

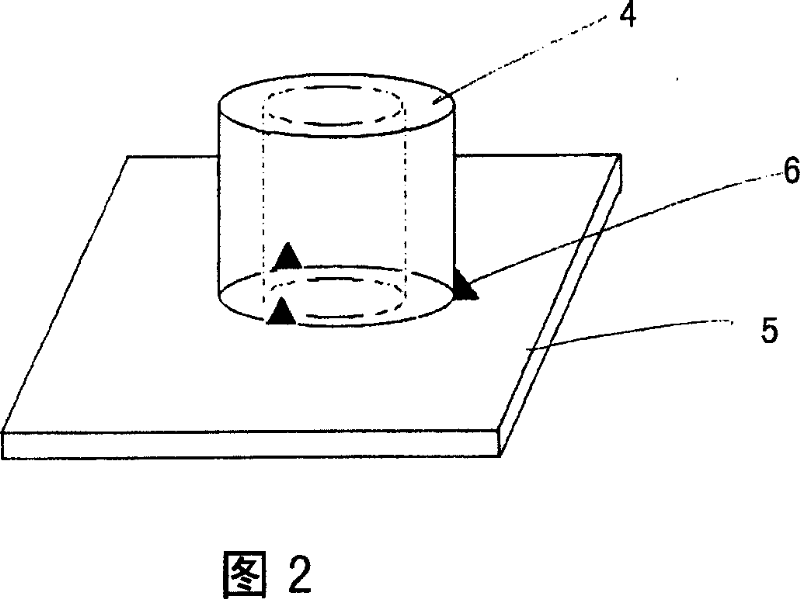

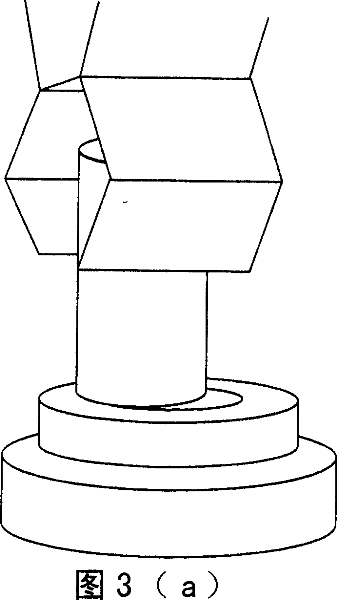

[0081] Taking the RTX (repeatability 0.2mm) robot as an example, the method of the present invention can realize the assembly of the following circular shaft 3 and circular hole 4: The radius of the hole 4 is R n = 20.01mm, the radius of shaft 3 is R P = 19.98mm, the length of the shaft 3 is 50mm, the assembly process is shown in Figure 3.

Example Embodiment

Specific Example 2

[0082] Take the RTX (repetition accuracy of 0.2mm) robot as an example, the method of the present invention can realize the assembly of the following triangular axis 3 and triangular hole 4: The radius of the hole 4 is R n = 20.01mm, the radius of shaft 3 is R P = 19.98mm, the length of the shaft 3 is 50mm, the assembly process is shown in Figure 4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com