Electronic product with casing mounting-dismounting structure

A technology for electronic products and casings, applied in the field of electronic products, can solve the problems of increasing the number of parts, time-consuming and laborious, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Please refer to FIG. 1 , which is a schematic diagram of the use state of the first preferred embodiment of the present invention, which is an electronic product of a computer host 6 assembled with a casing disassembly structure 5 of the present invention.

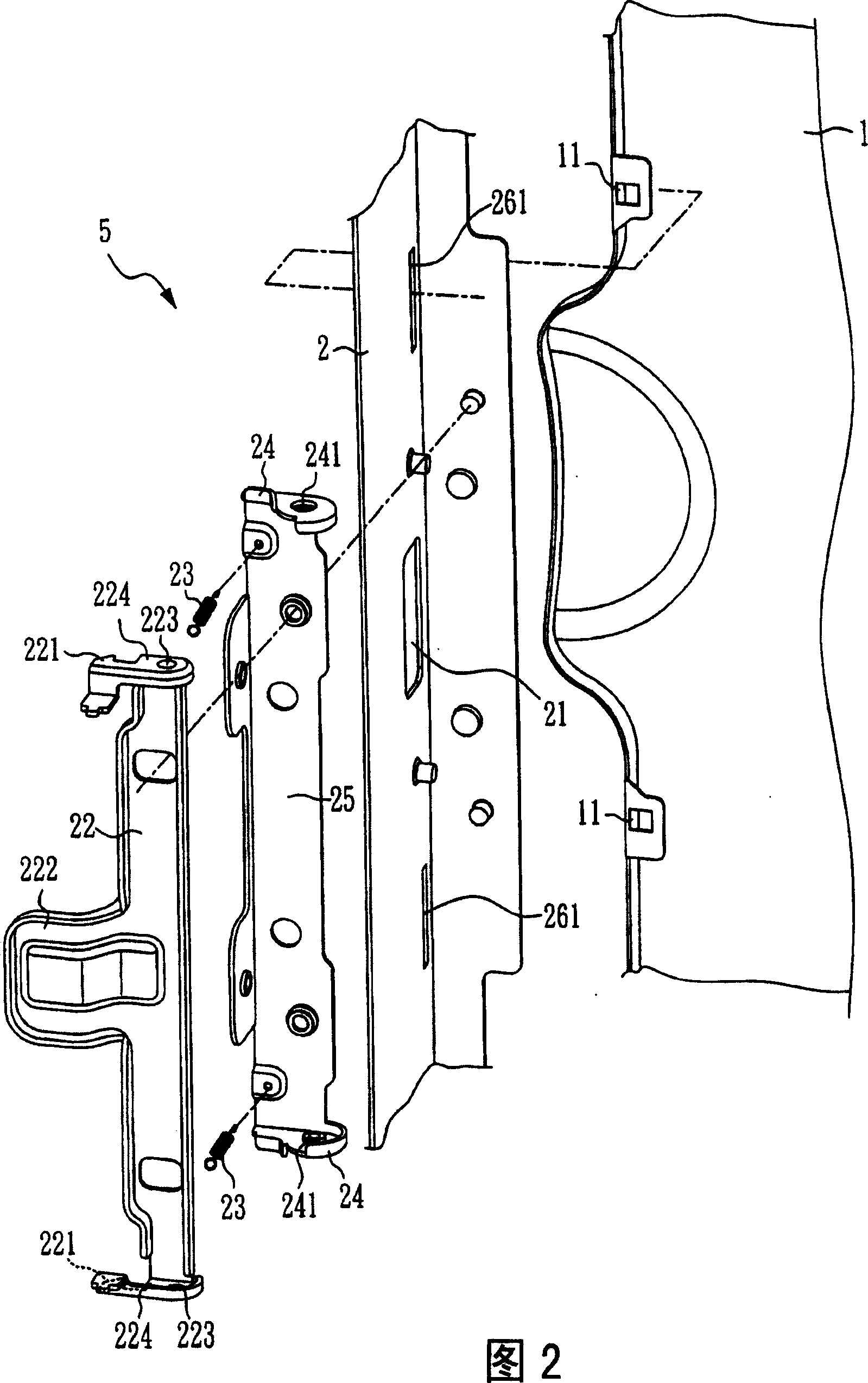

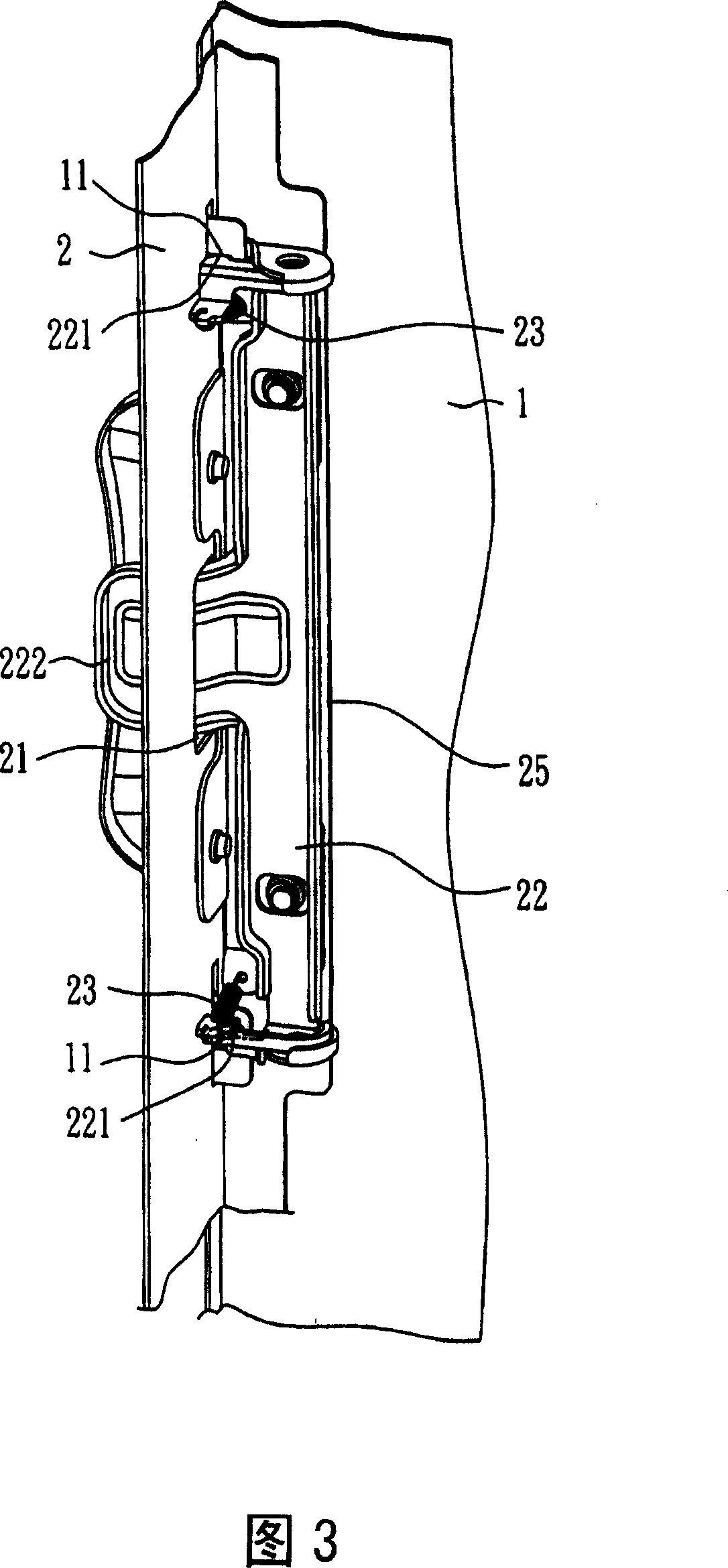

[0028] Please also refer to FIG. 2 which is an exploded view of the first preferred embodiment of the present invention, and FIG. 3 is an assembled view of the first preferred embodiment of the present invention, which shows that the above-mentioned casing disassembly structure 5 includes a first casing 1, and a second casing 2, and the first casing 1 includes two first engaging portions 11, in this embodiment, the two first engaging portions 11 are respectively a first opening, and They are respectively located on two sides of the first casing 1 .

[0029] In addition, the second casing 2 of the casing dismounting structure 5 in the drawing is adjacent to the first casing 1, and the second casing 2 includes a rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com