Full-automatic grain gradation screening machine

A kind of grain sorting machine, fully automatic technology, applied in the direction of solid separation, filter screen, grille, etc., can solve the problems of unclear diversion, low efficiency, inconvenient movement, etc., and achieve the effect of accurate grade and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

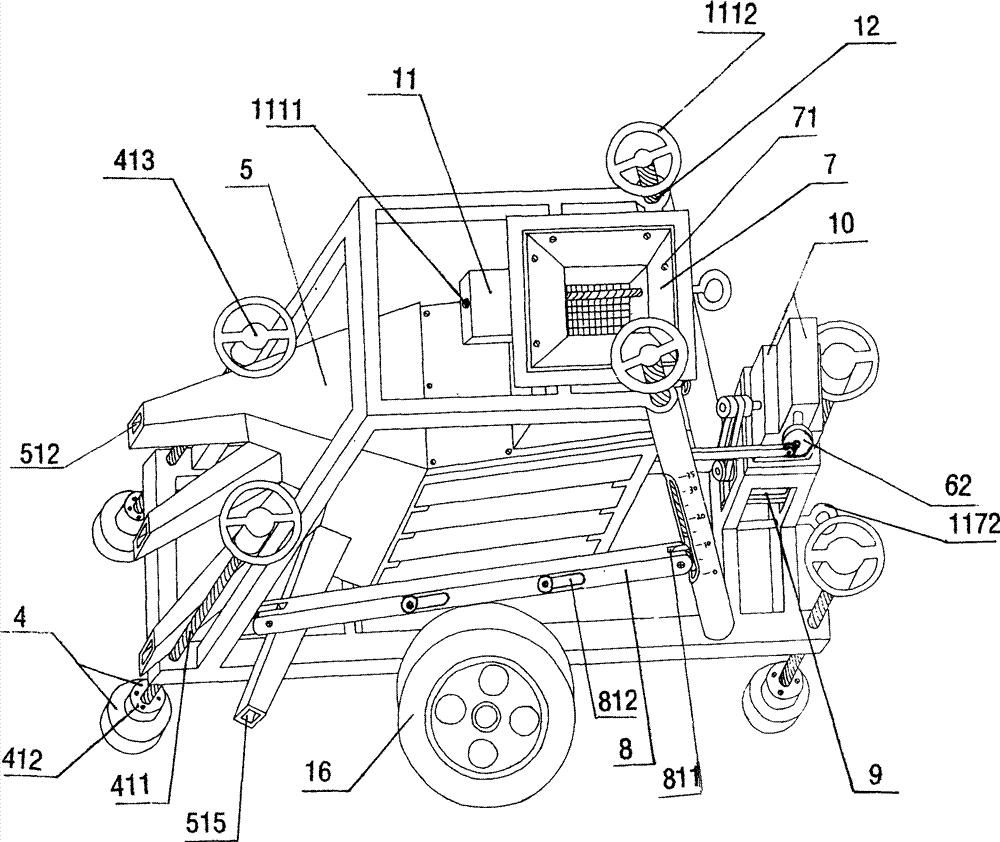

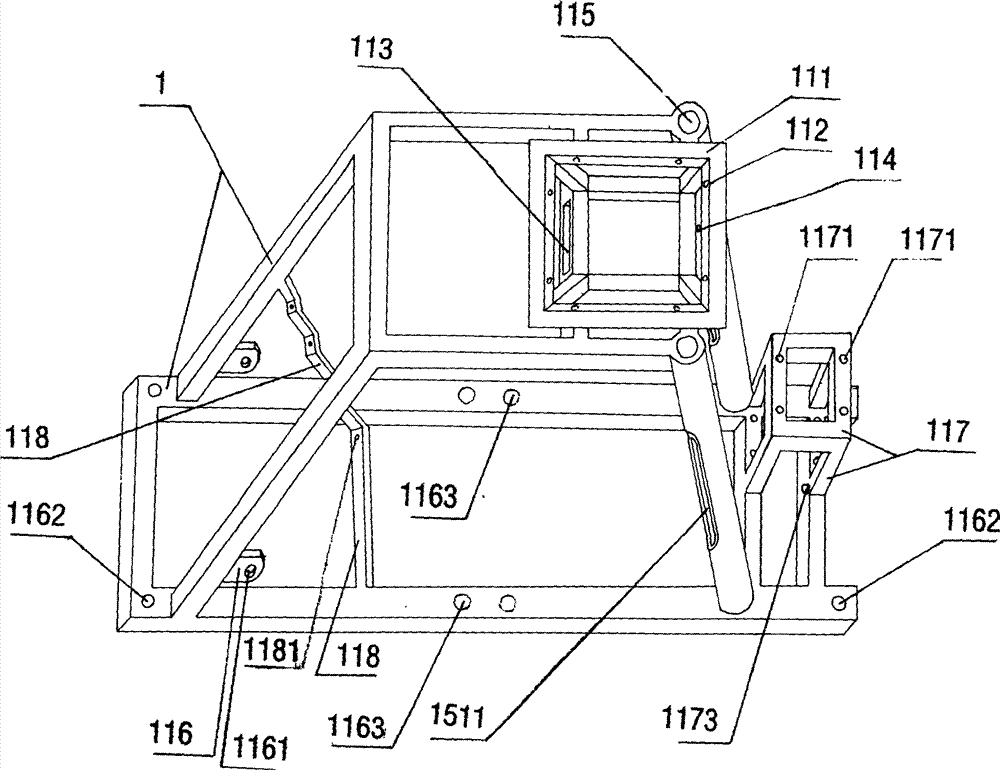

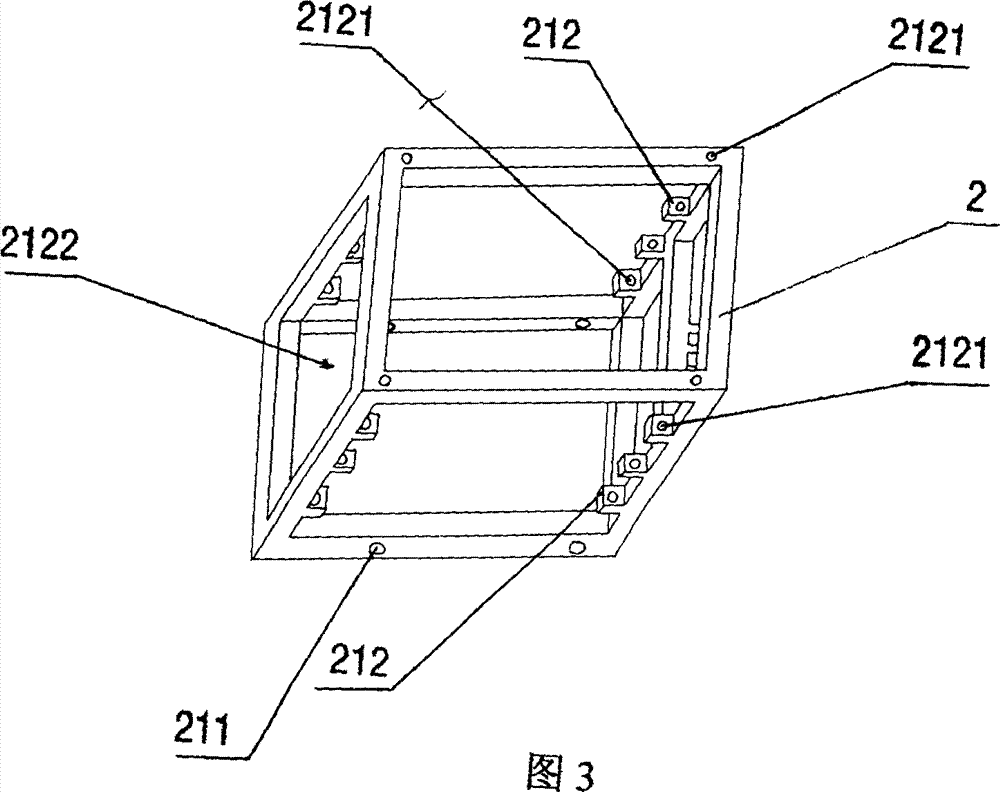

[0017] The present invention includes a frame body 1, a moving frame 2, a frame slot cover 3, a lifting support seat 4, a grade box 5, a connecting rod 6, a funnel 7, a moving arm 8, a motor 9, a reducer 10, a pull-in plate 11, an adjustment Shaft 12, shaft 13, sieve 14, handle bar 15, travel wheel 16, etc.; please refer to 1, figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10As shown, the hole 112 frame 111 opposite to the hole 71 for inserting and tightening the funnel 7 is provided at the rear portion above the frame body 1, and the lateral through groove 113 for inserting the pull-in plate 11 is provided on the lower beam of the frame 111. On the beam opposite to the through groove 113, there is a hole 114 through which the handle rod 15 in the hole 111 on the pull-in plate 11 passes through. On both sides of the hole 114, there are connected and inclined cylindrical tubes connected with the bottom beam of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com