Threading holder of sewing machine

A technology of clamping mechanism and sewing machine, which is applied to the mechanism of cutting thread in sewing machine, sewing machine components, sewing equipment, etc., and can solve the problems of complex structure of upper thread clamping components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

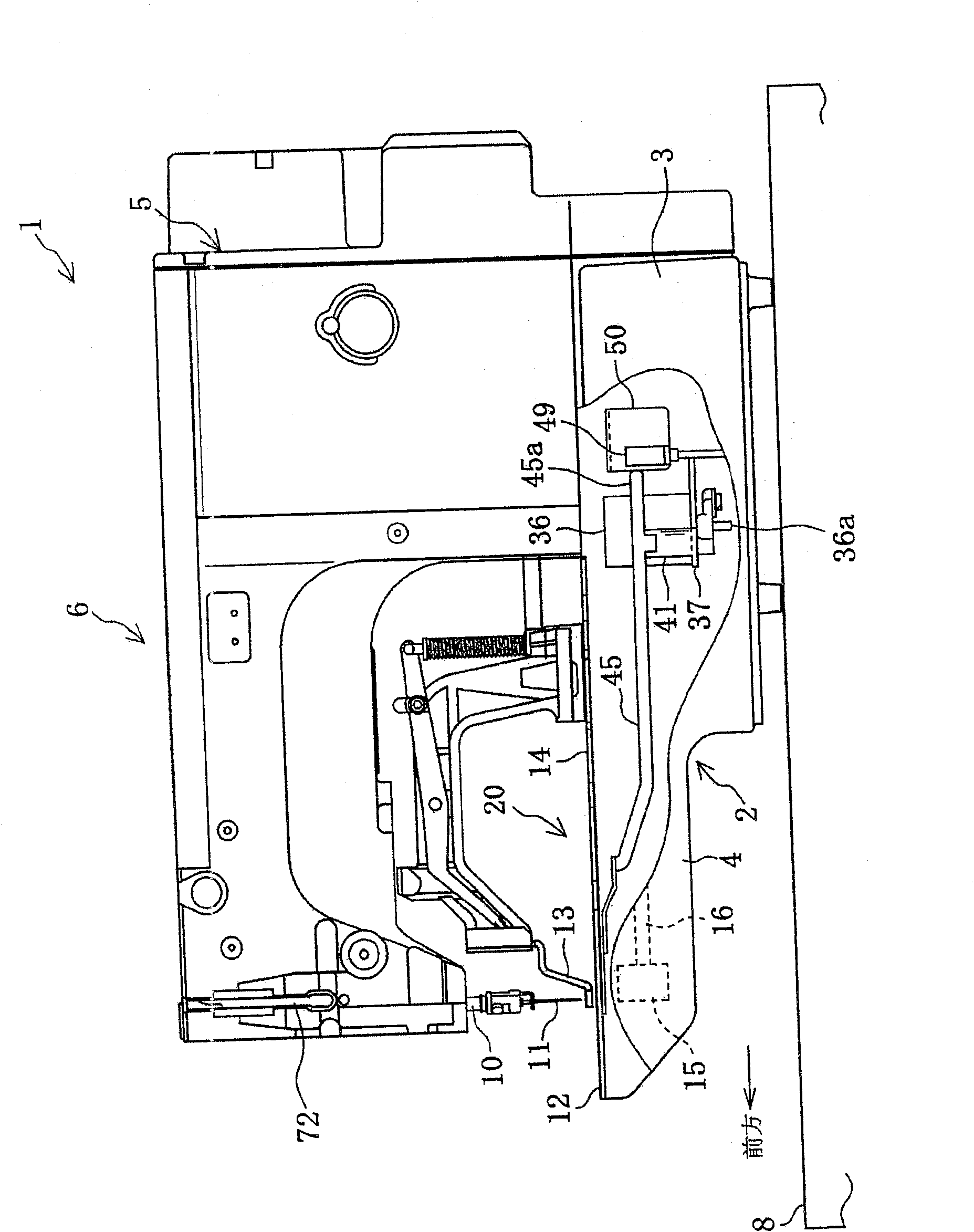

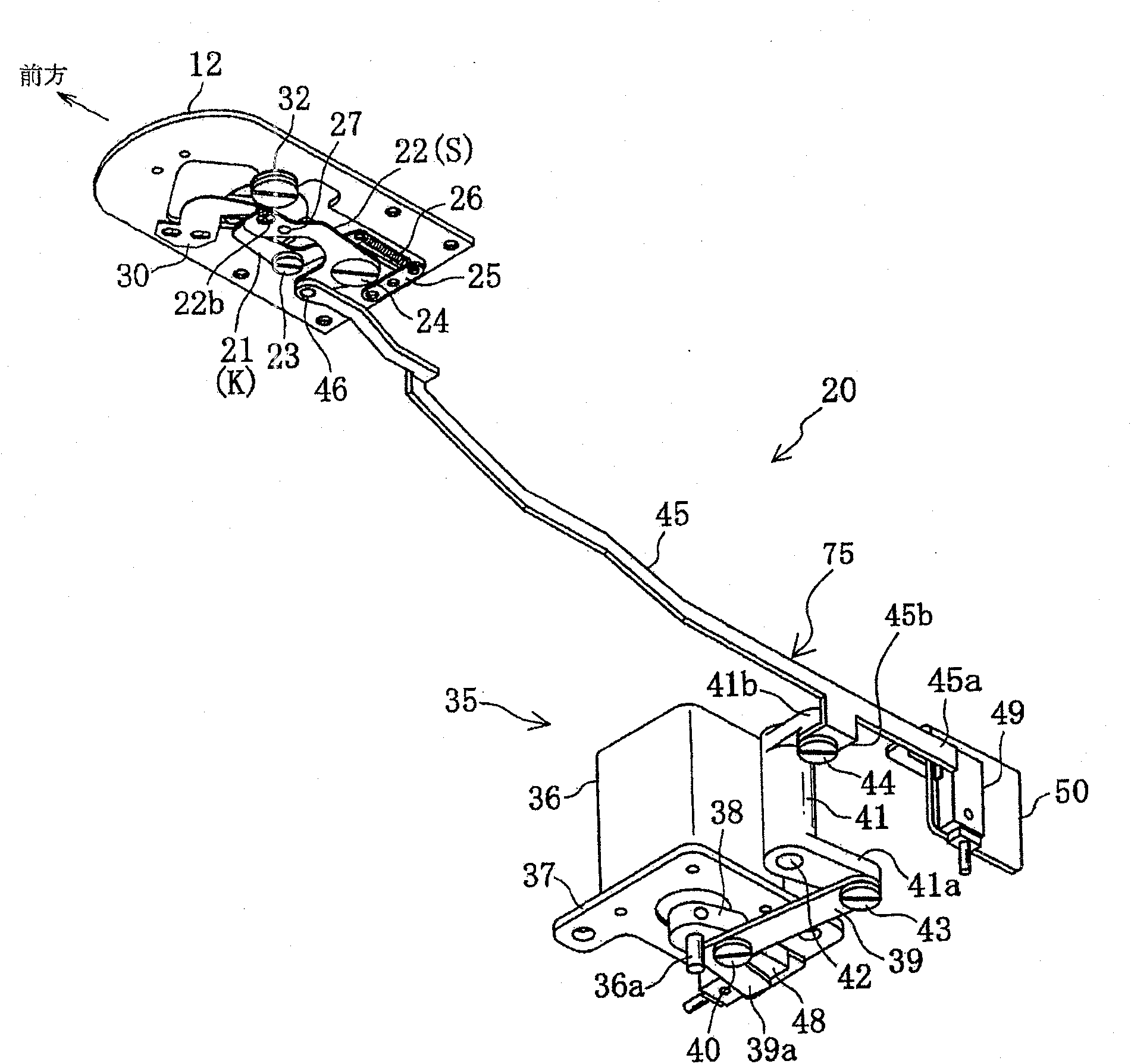

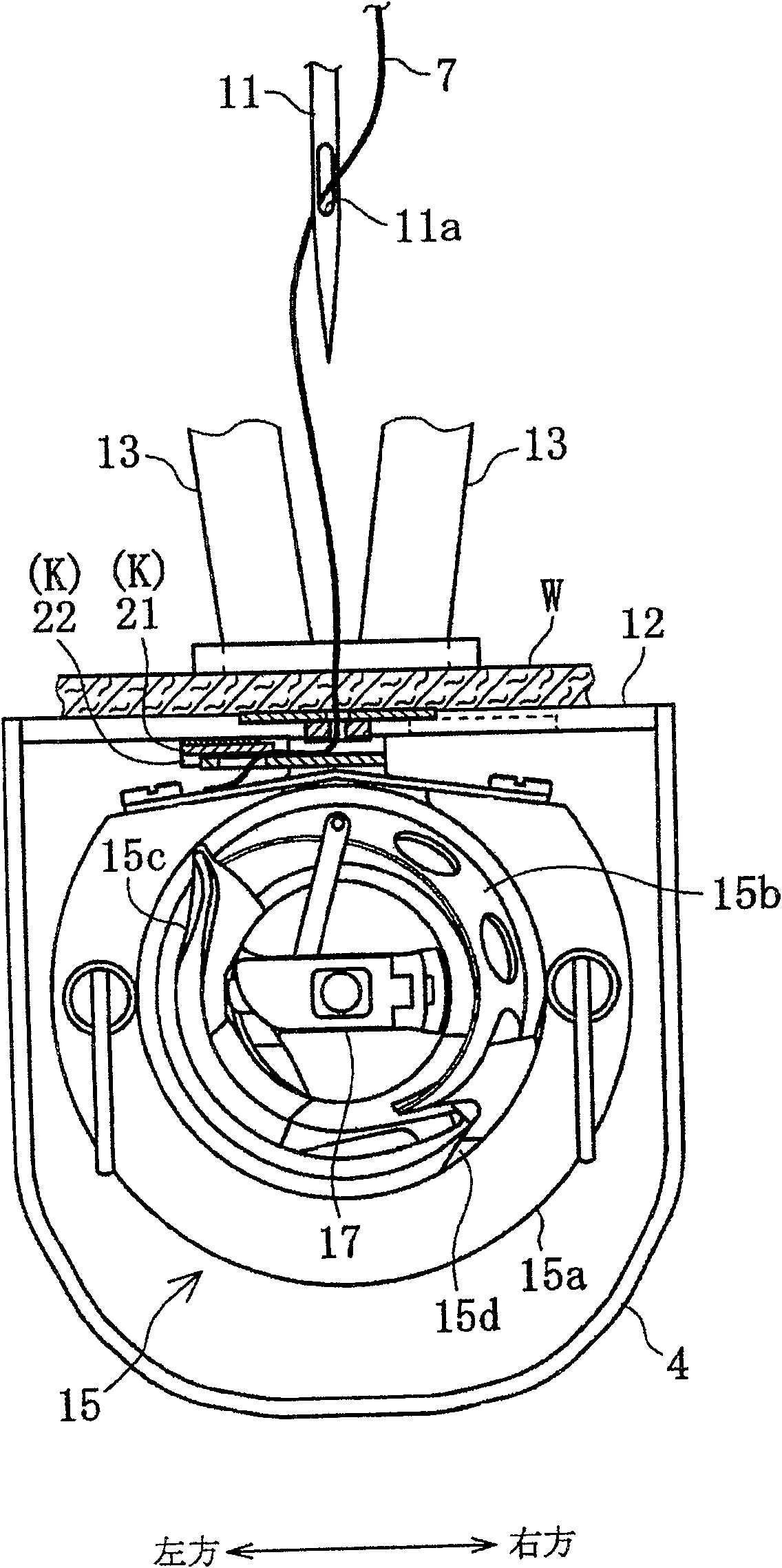

[0019] Refer below Figure 1 to Figure 12 Examples of the present invention will be described.

[0020] Such as figure 1 As shown, the electronic bartack reinforcement sewing machine 1 is set on the workbench 8 . This electronic bar tack reinforcement sewing machine 1 is composed of a base plate 2, a pillar portion 5 extending upward from the rear end of the base plate 2, and an arm portion 6 extending forward from the upper end of the pillar portion 5. The arm portion 6 is connected to the base plate. The upper part of part 2 faces. The bottom plate portion 2 and the arm portion 6 are relatively long in the front-rear direction and relatively short in the left-right direction.

[0021] An operation panel 9 is attached to the workbench 8 . The operation panel 9 is equipped with a liquid crystal display 9a, a selector switch 9b for selecting the type of tack reinforcement stitches and the pattern of the tack reinforcement stitches, and whether to set the end of the upper th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com