Zirconia's Role in Eco-Friendly Manufacturing Processes

Zirconia in Green Manufacturing: Background and Objectives

Zirconia, a versatile ceramic material, has emerged as a key player in the pursuit of eco-friendly manufacturing processes. The evolution of zirconia's role in green manufacturing can be traced back to the late 20th century when environmental concerns began to shape industrial practices. As global awareness of climate change and resource depletion grew, manufacturers sought innovative materials and methods to reduce their environmental footprint.

The technological trajectory of zirconia in eco-friendly manufacturing has been marked by continuous improvements in material properties and processing techniques. Initially, zirconia was primarily valued for its exceptional mechanical strength and thermal resistance. However, researchers and engineers soon recognized its potential to contribute to sustainable production methods. This realization led to a surge in research and development efforts aimed at harnessing zirconia's unique characteristics for green manufacturing applications.

One of the key trends in zirconia's evolution has been the focus on energy efficiency. As manufacturing industries faced increasing pressure to reduce energy consumption, zirconia-based components and coatings emerged as effective solutions. The material's low thermal conductivity and high temperature stability enabled the development of more efficient thermal barrier coatings for industrial equipment, resulting in significant energy savings across various sectors.

Another important aspect of zirconia's role in eco-friendly manufacturing has been its contribution to waste reduction and resource conservation. The durability and wear resistance of zirconia-based tools and components have led to extended product lifecycles, reducing the need for frequent replacements and minimizing waste generation. Additionally, the material's chemical inertness has made it valuable in developing corrosion-resistant equipment, further enhancing the longevity of industrial assets.

The technological objectives for zirconia in green manufacturing are multifaceted and ambitious. Researchers and industry leaders are striving to further enhance the material's properties to maximize its environmental benefits. This includes developing new zirconia composites with improved performance characteristics, optimizing manufacturing processes to reduce energy consumption and emissions, and exploring novel applications that can replace less sustainable materials across various industries.

As we look to the future, the role of zirconia in eco-friendly manufacturing is expected to expand significantly. The ongoing push for circular economy principles and the increasing adoption of advanced manufacturing technologies present new opportunities for zirconia-based solutions. From additive manufacturing to smart, self-healing materials, zirconia is poised to play a crucial role in shaping the next generation of sustainable production methods.

Market Demand for Eco-Friendly Manufacturing Solutions

The market demand for eco-friendly manufacturing solutions has been steadily increasing in recent years, driven by growing environmental concerns, stricter regulations, and consumer preferences for sustainable products. This trend has created significant opportunities for innovative materials and processes that can reduce the environmental impact of industrial production.

Zirconia, a versatile ceramic material, has emerged as a promising candidate for eco-friendly manufacturing processes. Its unique properties, including high strength, thermal stability, and chemical resistance, make it suitable for a wide range of applications in various industries. The global zirconia market is expected to grow substantially, with projections indicating a compound annual growth rate (CAGR) of over 5% in the coming years.

One of the key drivers of market demand for zirconia in eco-friendly manufacturing is its potential to replace less sustainable materials. For instance, in the automotive industry, zirconia-based components can reduce vehicle weight, leading to improved fuel efficiency and lower emissions. Similarly, in the energy sector, zirconia's high-temperature resistance makes it valuable for developing more efficient and cleaner energy production technologies.

The electronics industry is another significant market for zirconia in eco-friendly manufacturing. As consumer electronics become increasingly prevalent, there is a growing need for materials that can enhance device performance while minimizing environmental impact. Zirconia's electrical properties and durability make it an attractive option for various electronic components, potentially reducing e-waste and improving product longevity.

In the healthcare sector, the demand for biocompatible and durable materials has led to increased interest in zirconia-based medical devices and implants. This application not only offers improved patient outcomes but also contributes to sustainability by reducing the need for frequent replacements and minimizing medical waste.

The construction industry is also showing a growing interest in zirconia-based materials for eco-friendly building solutions. Zirconia's strength and resistance to weathering make it an excellent candidate for developing more durable and energy-efficient building materials, potentially reducing the environmental impact of construction and maintenance activities.

As industries continue to seek ways to reduce their carbon footprint and improve sustainability, the market demand for zirconia in eco-friendly manufacturing processes is expected to expand further. This trend is likely to drive innovation in zirconia production methods, application techniques, and product development across various sectors, creating new opportunities for businesses and researchers in the field of sustainable materials and manufacturing.

Current Zirconia Applications and Environmental Challenges

Zirconia, a versatile ceramic material, has found widespread applications across various industries due to its exceptional properties. In the context of eco-friendly manufacturing processes, zirconia plays a significant role in enhancing sustainability and reducing environmental impact. Currently, zirconia is extensively used in dental and medical implants, automotive components, fuel cells, and advanced ceramics for industrial applications.

In the dental industry, zirconia-based crowns and bridges have become increasingly popular due to their biocompatibility, durability, and aesthetic appeal. These prosthetics offer a more environmentally friendly alternative to traditional metal-based options, as they require less energy-intensive manufacturing processes and do not release harmful metal ions into the body or environment.

The automotive sector has embraced zirconia in the production of oxygen sensors, which are crucial for optimizing engine performance and reducing emissions. These sensors contribute to improved fuel efficiency and lower carbon dioxide emissions, aligning with global efforts to combat climate change. Additionally, zirconia-based thermal barrier coatings are used in engine components, enhancing their durability and thermal efficiency.

In the energy sector, zirconia plays a vital role in solid oxide fuel cells (SOFCs), which offer a clean and efficient method of electricity generation. SOFCs utilizing zirconia electrolytes can operate at high temperatures, enabling the use of various fuel sources, including hydrogen and natural gas, with minimal environmental impact.

Despite its numerous benefits, the widespread adoption of zirconia in eco-friendly manufacturing processes faces several environmental challenges. The production of zirconia itself can be energy-intensive, particularly during the high-temperature sintering process. This energy consumption contributes to carbon emissions, potentially offsetting some of the material's environmental benefits.

Another challenge lies in the sourcing of zirconium, the primary raw material for zirconia production. Mining and processing zirconium ores can have significant environmental impacts, including habitat destruction, water pollution, and soil degradation. Sustainable mining practices and efficient extraction methods are crucial to mitigate these effects.

The recyclability of zirconia-based products also presents a challenge. While zirconia is highly durable, its end-of-life management remains a concern. Developing effective recycling techniques for zirconia-containing products is essential to reduce waste and promote a circular economy.

As industries strive for greater sustainability, addressing these environmental challenges associated with zirconia production and use becomes paramount. Innovations in manufacturing processes, such as low-temperature sintering techniques and the use of renewable energy sources, are being explored to reduce the carbon footprint of zirconia production. Additionally, research into alternative raw material sources and improved recycling methods is ongoing to enhance the overall environmental profile of zirconia-based products.

Existing Zirconia-Enabled Eco-Friendly Processes

01 Zirconia synthesis and processing

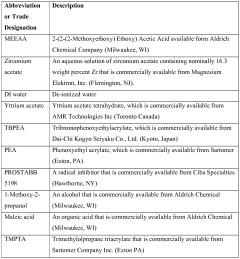

Various methods for synthesizing and processing zirconia are explored, including chemical vapor deposition, sol-gel techniques, and hydrothermal processes. These methods aim to produce high-quality zirconia with controlled properties for different applications.- Zirconia synthesis and processing: Various methods for synthesizing and processing zirconia materials, including techniques for controlling particle size, crystalline structure, and purity. This encompasses sol-gel processes, hydrothermal synthesis, and other advanced manufacturing techniques to produce zirconia with specific properties for different applications.

- Zirconia-based composites and coatings: Development of composite materials and coatings incorporating zirconia to enhance mechanical, thermal, and chemical properties. This includes zirconia-reinforced ceramics, zirconia-containing protective coatings, and multi-layer structures utilizing zirconia for improved performance in various industrial and technological applications.

- Dental and biomedical applications of zirconia: Utilization of zirconia in dental and biomedical fields, focusing on its biocompatibility, aesthetic properties, and mechanical strength. This covers zirconia-based dental implants, prosthetics, and other medical devices that leverage the material's unique characteristics for improved patient outcomes.

- Zirconia in catalysis and fuel cells: Applications of zirconia in catalytic processes and fuel cell technology, exploiting its oxygen ion conductivity and stability at high temperatures. This includes the use of zirconia as a catalyst support, in solid oxide fuel cells, and in other energy-related applications where its properties contribute to improved efficiency and durability.

- Stabilization and phase transformation of zirconia: Techniques for stabilizing zirconia in its various crystalline phases and controlling phase transformations. This involves the use of dopants, heat treatments, and other methods to manipulate the crystal structure of zirconia for specific applications, enhancing its mechanical properties and thermal stability.

02 Zirconia-based dental materials

Zirconia is widely used in dental applications due to its biocompatibility and mechanical properties. Research focuses on improving the strength, aesthetics, and durability of zirconia-based dental materials, such as crowns, bridges, and implants.Expand Specific Solutions03 Zirconia in fuel cells and sensors

Zirconia, particularly yttria-stabilized zirconia, is utilized in solid oxide fuel cells and oxygen sensors. Research aims to enhance the ionic conductivity and stability of zirconia-based materials for improved performance in these applications.Expand Specific Solutions04 Zirconia coatings and thin films

Zirconia coatings and thin films are developed for various applications, including thermal barrier coatings, wear-resistant surfaces, and optical coatings. Research focuses on improving deposition techniques and enhancing the properties of these coatings.Expand Specific Solutions05 Zirconia nanoparticles and composites

Zirconia nanoparticles and composites are investigated for their unique properties and potential applications in areas such as catalysis, biomedicine, and advanced materials. Research aims to control particle size, morphology, and dispersion in various matrices.Expand Specific Solutions

Key Players in Zirconia-Based Green Manufacturing

The eco-friendly manufacturing landscape utilizing zirconia is evolving rapidly, with the market in a growth phase. The global zirconia market size is expanding, driven by increasing demand for sustainable materials across industries. Technologically, zirconia applications in eco-friendly processes are advancing, with varying levels of maturity. Companies like 3M Innovative Properties Co., Saint-Gobain Centre de Recherches et d'Études Européen SAS, and Toyota Motor Corp. are at the forefront, developing innovative applications. Emerging players such as Donghua University and UBE Corp. are contributing to research and development. The competitive landscape is diverse, with established materials giants, automotive manufacturers, and specialized ceramic companies all vying for market share in this growing sector.

Toyota Motor Corp.

LG Chem Ltd.

Innovative Zirconia Technologies for Sustainability

- A ceramic composite is formulated using zirconia particles stabilized with yttria, silver and platinum particles bonded to the zirconia surface, and tourmaline particles, dispersed in water with a water-soluble binder, to create an eco-friendly functional paint that integrates far-infrared emission, antibacterial, and anion-emitting properties.

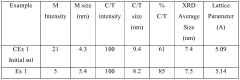

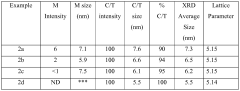

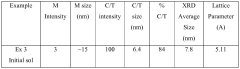

- Zirconia-based particles with 0.02 to 20 mole percent lanthanide element oxide and 0 to 15 mole percent yttrium oxide are synthesized using a hydrothermal treatment method, resulting in crystalline particles with an average primary size of no greater than 100 nanometers, which are then used in sols, composites, and sintered bodies to enhance mechanical properties and refractive index.

Life Cycle Assessment of Zirconia in Manufacturing

Life Cycle Assessment (LCA) of zirconia in manufacturing processes is a crucial step in evaluating its eco-friendly potential. This comprehensive analysis examines the environmental impacts associated with zirconia throughout its entire lifecycle, from raw material extraction to end-of-life disposal or recycling.

The initial phase of the LCA focuses on the extraction and processing of zirconium minerals, primarily zircon. This stage involves mining operations, which can have significant environmental implications, including land disturbance, energy consumption, and potential water pollution. The subsequent refining process to obtain zirconium dioxide (zirconia) also requires substantial energy input and may generate chemical waste.

Manufacturing processes utilizing zirconia are the next key area of assessment. Zirconia's high melting point and excellent thermal properties make it energy-efficient in various applications, potentially reducing overall energy consumption in manufacturing. Its durability and resistance to wear and corrosion can lead to longer-lasting products, thereby decreasing the need for frequent replacements and associated resource consumption.

The use phase of zirconia-containing products is generally characterized by improved performance and longevity. For instance, in cutting tools and machinery components, zirconia's properties contribute to reduced friction and wear, leading to energy savings and extended equipment life. In thermal barrier coatings, zirconia's low thermal conductivity enhances energy efficiency in high-temperature applications, such as gas turbines.

End-of-life considerations for zirconia products are crucial in the LCA. While zirconia itself is not biodegradable, its durability often means that products containing it have longer lifespans. Recycling and recovery of zirconia from end-of-life products are technically feasible but may be energy-intensive. The potential for reuse in other applications should be explored to maximize resource efficiency.

Comparative analysis with alternative materials is essential in the LCA. Zirconia's performance benefits and longevity must be weighed against the environmental impacts of its production. In many cases, the extended lifespan and improved efficiency of zirconia-containing products may offset the initial environmental costs of production.

The LCA should also consider potential improvements in zirconia production and application technologies. Advancements in more energy-efficient refining processes, cleaner mining practices, and innovative recycling techniques could further enhance zirconia's eco-friendly profile in manufacturing.

In conclusion, a thorough Life Cycle Assessment of zirconia in manufacturing reveals a complex interplay of environmental impacts and benefits. While its production can be resource-intensive, the long-term advantages in product performance, durability, and energy efficiency often contribute positively to overall environmental sustainability in manufacturing processes.

Regulatory Framework for Eco-Friendly Manufacturing Materials

The regulatory framework for eco-friendly manufacturing materials plays a crucial role in shaping the adoption and implementation of zirconia in sustainable production processes. As governments and international organizations increasingly prioritize environmental protection and sustainable development, manufacturers must navigate a complex landscape of regulations, standards, and guidelines.

At the global level, the United Nations Sustainable Development Goals (SDGs) provide a broad framework for promoting sustainable industrialization. Goal 9, in particular, emphasizes the importance of building resilient infrastructure, promoting inclusive and sustainable industrialization, and fostering innovation. This overarching goal has influenced the development of more specific regulations and standards related to eco-friendly manufacturing materials, including zirconia.

The European Union has been at the forefront of implementing stringent environmental regulations that impact the use of materials in manufacturing. The Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation, for instance, requires manufacturers to register and assess the safety of chemical substances used in their products. Zirconia, as a ceramic material, must comply with these regulations to ensure its safe use in eco-friendly manufacturing processes.

In the United States, the Environmental Protection Agency (EPA) oversees regulations related to the use of materials in manufacturing. The Toxic Substances Control Act (TSCA) provides a framework for evaluating and regulating chemical substances, including those used in eco-friendly manufacturing. Manufacturers utilizing zirconia must ensure compliance with these regulations to maintain their operations within the US market.

International standards organizations, such as the International Organization for Standardization (ISO), have developed specific standards related to environmental management and sustainable manufacturing. ISO 14001, for example, provides a framework for organizations to implement effective environmental management systems. Manufacturers incorporating zirconia into their eco-friendly processes often seek certification under these standards to demonstrate their commitment to sustainability.

The regulatory landscape also includes industry-specific standards and certifications. For instance, the Leadership in Energy and Environmental Design (LEED) certification system, developed by the U.S. Green Building Council, encourages the use of sustainable materials in construction. Zirconia's potential applications in eco-friendly building materials may be influenced by such certification requirements.

As the focus on circular economy principles intensifies, regulations are evolving to promote the reuse and recycling of materials. The EU's Circular Economy Action Plan, for example, aims to make sustainable products the norm and reduce waste. This regulatory shift may impact the design and manufacturing processes involving zirconia, encouraging innovations in material recovery and recycling techniques.

Compliance with these regulatory frameworks often requires manufacturers to conduct life cycle assessments (LCAs) of their products and processes. These assessments evaluate the environmental impact of materials like zirconia throughout their entire life cycle, from raw material extraction to end-of-life disposal or recycling. The results of these assessments can influence regulatory decisions and drive improvements in eco-friendly manufacturing processes.