Toward Sustainable Hypochlorous Acid Production: Challenges and Solutions

AUG 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

HOCl Production Background and Objectives

Hypochlorous acid (HOCl) has emerged as a crucial compound in various industries, including water treatment, healthcare, and agriculture. Its powerful disinfectant properties, coupled with its eco-friendly nature, have driven increased interest in sustainable production methods. The evolution of HOCl production technology spans several decades, with significant advancements in efficiency and environmental impact reduction.

The primary objective in HOCl production is to develop sustainable, cost-effective, and scalable methods that minimize environmental impact while maintaining product quality and efficacy. This goal aligns with the growing global emphasis on green chemistry and sustainable industrial practices. The technology aims to address the challenges of traditional chlorine-based disinfectants, which often pose environmental and health risks.

Recent technological trends in HOCl production focus on electrolysis-based methods, which offer advantages in terms of on-site generation, reduced chemical handling, and improved safety. These methods typically involve the electrolysis of salt water, producing HOCl without the need for hazardous chemical precursors. The trend towards miniaturization and modular systems has also gained traction, allowing for more flexible and localized production.

Another significant trend is the integration of renewable energy sources in HOCl production processes. This approach aims to reduce the carbon footprint associated with production and aligns with broader sustainability goals. Researchers are exploring solar-powered electrolysis systems and other renewable energy integration methods to enhance the overall sustainability of HOCl production.

The development of advanced electrode materials and catalysts represents a key area of technological progress. These innovations aim to improve the efficiency of electrolysis, reduce energy consumption, and extend the lifespan of production equipment. Nanotechnology and advanced material science play crucial roles in this aspect of HOCl production technology.

In terms of market drivers, the increasing demand for safe and effective disinfectants, particularly in the wake of global health crises, has significantly boosted interest in HOCl production technology. The compound's broad-spectrum antimicrobial properties, combined with its non-toxic nature, make it an attractive alternative to traditional disinfectants in various applications.

Looking ahead, the technological objectives for HOCl production include further improvements in energy efficiency, the development of more durable and cost-effective electrode materials, and the optimization of production processes for different scales and applications. Additionally, there is a growing focus on enhancing the stability and shelf life of HOCl solutions, which remains a challenge due to the compound's reactive nature.

The primary objective in HOCl production is to develop sustainable, cost-effective, and scalable methods that minimize environmental impact while maintaining product quality and efficacy. This goal aligns with the growing global emphasis on green chemistry and sustainable industrial practices. The technology aims to address the challenges of traditional chlorine-based disinfectants, which often pose environmental and health risks.

Recent technological trends in HOCl production focus on electrolysis-based methods, which offer advantages in terms of on-site generation, reduced chemical handling, and improved safety. These methods typically involve the electrolysis of salt water, producing HOCl without the need for hazardous chemical precursors. The trend towards miniaturization and modular systems has also gained traction, allowing for more flexible and localized production.

Another significant trend is the integration of renewable energy sources in HOCl production processes. This approach aims to reduce the carbon footprint associated with production and aligns with broader sustainability goals. Researchers are exploring solar-powered electrolysis systems and other renewable energy integration methods to enhance the overall sustainability of HOCl production.

The development of advanced electrode materials and catalysts represents a key area of technological progress. These innovations aim to improve the efficiency of electrolysis, reduce energy consumption, and extend the lifespan of production equipment. Nanotechnology and advanced material science play crucial roles in this aspect of HOCl production technology.

In terms of market drivers, the increasing demand for safe and effective disinfectants, particularly in the wake of global health crises, has significantly boosted interest in HOCl production technology. The compound's broad-spectrum antimicrobial properties, combined with its non-toxic nature, make it an attractive alternative to traditional disinfectants in various applications.

Looking ahead, the technological objectives for HOCl production include further improvements in energy efficiency, the development of more durable and cost-effective electrode materials, and the optimization of production processes for different scales and applications. Additionally, there is a growing focus on enhancing the stability and shelf life of HOCl solutions, which remains a challenge due to the compound's reactive nature.

Market Analysis for Sustainable HOCl

The global market for sustainable hypochlorous acid (HOCl) production is experiencing significant growth, driven by increasing awareness of environmental concerns and the need for eco-friendly disinfection solutions. The demand for HOCl has been steadily rising across various sectors, including healthcare, water treatment, agriculture, and household cleaning products.

In the healthcare sector, HOCl has gained traction as an effective and safe disinfectant, particularly in hospital settings and medical device sterilization. The ongoing global health challenges have further accelerated the adoption of HOCl-based solutions, contributing to market expansion. The water treatment industry has also shown a growing interest in sustainable HOCl production methods, as municipalities and industrial facilities seek more environmentally friendly alternatives to traditional chlorine-based disinfection systems.

The agriculture sector represents another significant market opportunity for sustainable HOCl. As concerns over chemical pesticide use continue to grow, farmers are increasingly turning to HOCl as a natural and effective solution for crop protection and post-harvest treatment. This trend is expected to drive substantial market growth in the coming years.

Consumer demand for eco-friendly household cleaning products has also fueled the market for sustainable HOCl. With increasing awareness of the environmental impact of traditional cleaning chemicals, consumers are seeking safer alternatives that maintain efficacy while reducing their ecological footprint. This shift in consumer preferences has led to the development of numerous HOCl-based cleaning products, further expanding the market.

The market for sustainable HOCl production is characterized by regional variations in adoption rates and regulatory frameworks. North America and Europe currently lead in terms of market size and technological advancements, with stringent environmental regulations driving innovation in sustainable production methods. However, the Asia-Pacific region is expected to witness the fastest growth, propelled by rapid industrialization, increasing healthcare expenditure, and growing environmental consciousness.

Key market drivers include the rising demand for safe and effective disinfection solutions, increasing focus on sustainable practices across industries, and growing awareness of the environmental impact of traditional chemical disinfectants. Challenges facing the market include the need for cost-effective production methods, ensuring product stability, and overcoming regulatory hurdles in certain regions.

In the healthcare sector, HOCl has gained traction as an effective and safe disinfectant, particularly in hospital settings and medical device sterilization. The ongoing global health challenges have further accelerated the adoption of HOCl-based solutions, contributing to market expansion. The water treatment industry has also shown a growing interest in sustainable HOCl production methods, as municipalities and industrial facilities seek more environmentally friendly alternatives to traditional chlorine-based disinfection systems.

The agriculture sector represents another significant market opportunity for sustainable HOCl. As concerns over chemical pesticide use continue to grow, farmers are increasingly turning to HOCl as a natural and effective solution for crop protection and post-harvest treatment. This trend is expected to drive substantial market growth in the coming years.

Consumer demand for eco-friendly household cleaning products has also fueled the market for sustainable HOCl. With increasing awareness of the environmental impact of traditional cleaning chemicals, consumers are seeking safer alternatives that maintain efficacy while reducing their ecological footprint. This shift in consumer preferences has led to the development of numerous HOCl-based cleaning products, further expanding the market.

The market for sustainable HOCl production is characterized by regional variations in adoption rates and regulatory frameworks. North America and Europe currently lead in terms of market size and technological advancements, with stringent environmental regulations driving innovation in sustainable production methods. However, the Asia-Pacific region is expected to witness the fastest growth, propelled by rapid industrialization, increasing healthcare expenditure, and growing environmental consciousness.

Key market drivers include the rising demand for safe and effective disinfection solutions, increasing focus on sustainable practices across industries, and growing awareness of the environmental impact of traditional chemical disinfectants. Challenges facing the market include the need for cost-effective production methods, ensuring product stability, and overcoming regulatory hurdles in certain regions.

Current Challenges in HOCl Synthesis

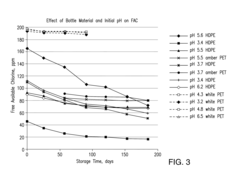

The synthesis of hypochlorous acid (HOCl) faces several significant challenges that hinder its sustainable production and widespread adoption. One of the primary issues is the instability of HOCl solutions. HOCl is highly reactive and tends to decompose rapidly, especially when exposed to light, heat, or organic matter. This instability necessitates careful handling, storage, and transportation procedures, which increase production costs and limit shelf life.

Another major challenge is the energy-intensive nature of traditional HOCl production methods. The most common industrial process, electrolysis of sodium chloride solutions, requires substantial electrical energy input. This high energy demand not only increases production costs but also raises environmental concerns due to the associated carbon footprint, particularly when the electricity source is not renewable.

The use of hazardous chemicals in HOCl production poses additional challenges. Many synthesis methods involve chlorine gas or other potentially dangerous precursors, which require stringent safety measures and specialized handling equipment. These safety requirements further escalate production costs and create potential environmental and health risks.

Scale-up difficulties present another significant hurdle in HOCl production. While small-scale synthesis may be relatively straightforward, maintaining consistent quality and efficiency at industrial scales can be problematic. Issues such as electrode fouling in electrolytic cells, uneven distribution of reactants, and heat management become more pronounced at larger scales, affecting product purity and yield.

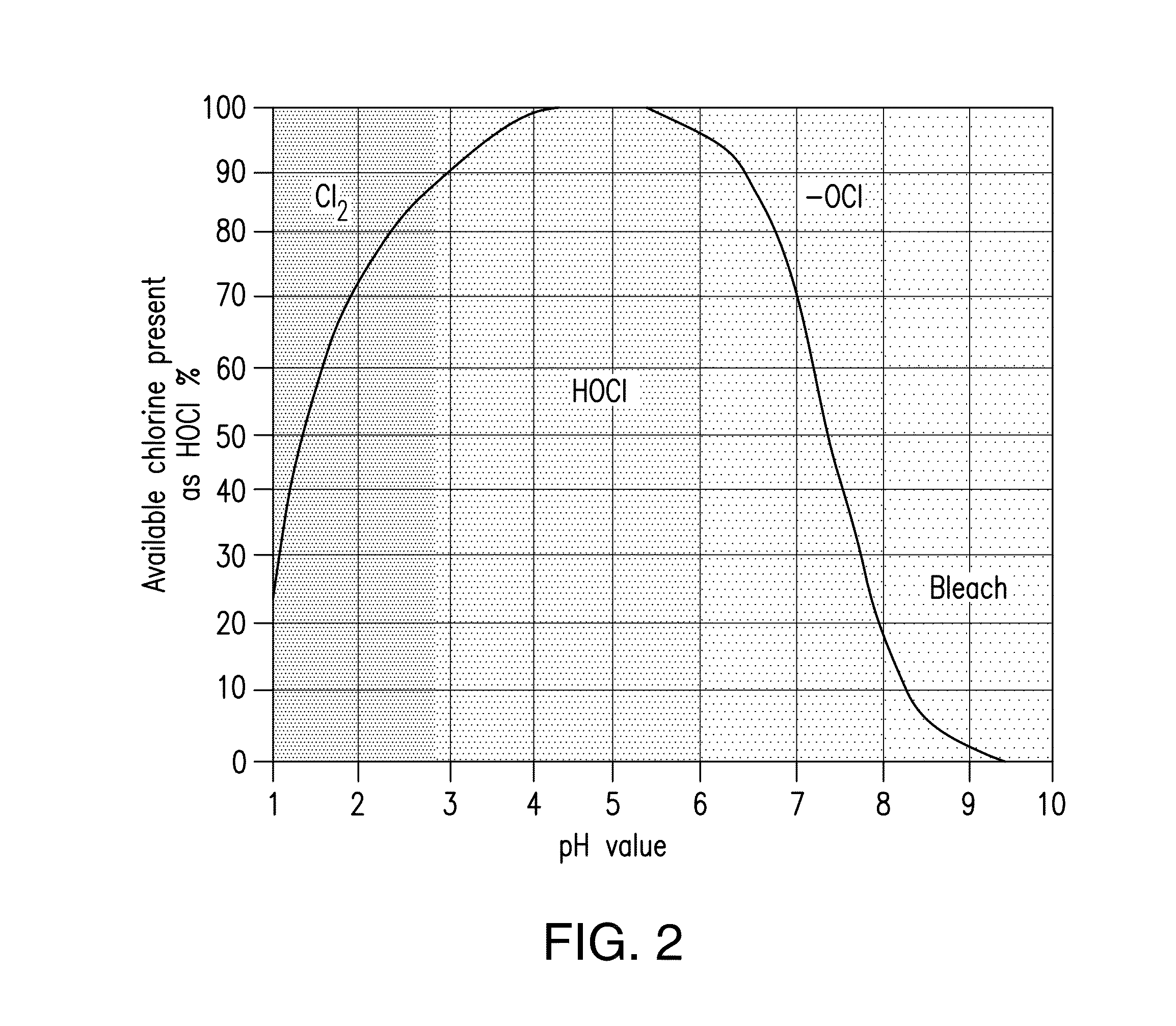

The purity and concentration control of HOCl solutions are also challenging aspects of production. Achieving and maintaining the desired concentration of HOCl without excessive formation of byproducts like chlorine gas or chlorate ions requires precise control of reaction conditions. This precision is difficult to maintain consistently, especially in large-scale operations.

Furthermore, the corrosive nature of HOCl solutions presents materials compatibility issues. Many common materials used in production equipment and storage containers are susceptible to degradation when in contact with HOCl, necessitating the use of specialized, often more expensive, corrosion-resistant materials.

Lastly, regulatory compliance and product standardization pose significant challenges. The varying regulations across different regions regarding the production, transport, and use of HOCl complicate its commercialization. Additionally, the lack of standardized production methods and quality control measures makes it difficult to ensure consistent product quality across different manufacturers, potentially limiting consumer trust and market adoption.

Another major challenge is the energy-intensive nature of traditional HOCl production methods. The most common industrial process, electrolysis of sodium chloride solutions, requires substantial electrical energy input. This high energy demand not only increases production costs but also raises environmental concerns due to the associated carbon footprint, particularly when the electricity source is not renewable.

The use of hazardous chemicals in HOCl production poses additional challenges. Many synthesis methods involve chlorine gas or other potentially dangerous precursors, which require stringent safety measures and specialized handling equipment. These safety requirements further escalate production costs and create potential environmental and health risks.

Scale-up difficulties present another significant hurdle in HOCl production. While small-scale synthesis may be relatively straightforward, maintaining consistent quality and efficiency at industrial scales can be problematic. Issues such as electrode fouling in electrolytic cells, uneven distribution of reactants, and heat management become more pronounced at larger scales, affecting product purity and yield.

The purity and concentration control of HOCl solutions are also challenging aspects of production. Achieving and maintaining the desired concentration of HOCl without excessive formation of byproducts like chlorine gas or chlorate ions requires precise control of reaction conditions. This precision is difficult to maintain consistently, especially in large-scale operations.

Furthermore, the corrosive nature of HOCl solutions presents materials compatibility issues. Many common materials used in production equipment and storage containers are susceptible to degradation when in contact with HOCl, necessitating the use of specialized, often more expensive, corrosion-resistant materials.

Lastly, regulatory compliance and product standardization pose significant challenges. The varying regulations across different regions regarding the production, transport, and use of HOCl complicate its commercialization. Additionally, the lack of standardized production methods and quality control measures makes it difficult to ensure consistent product quality across different manufacturers, potentially limiting consumer trust and market adoption.

Existing Sustainable HOCl Production Methods

01 Sustainable production methods

Developing eco-friendly and efficient methods for producing hypochlorous acid, focusing on reducing energy consumption and minimizing waste. This includes optimizing electrolysis processes, using renewable energy sources, and implementing closed-loop systems for resource recovery.- Sustainable production methods: Developing eco-friendly and efficient methods for producing hypochlorous acid, focusing on reducing energy consumption and minimizing waste. These methods may include electrochemical processes, membrane technology, or novel catalytic systems that improve yield and reduce environmental impact.

- Stabilization and shelf-life extension: Improving the stability and shelf-life of hypochlorous acid solutions through innovative formulations and packaging techniques. This may involve the use of specific additives, pH control mechanisms, or advanced storage systems to maintain the efficacy of the product over extended periods.

- Environmental impact reduction: Developing strategies to minimize the environmental footprint of hypochlorous acid production and use. This includes optimizing resource utilization, implementing closed-loop systems, and exploring biodegradable alternatives or byproducts that can be safely released into the environment.

- Sustainable applications and uses: Exploring new sustainable applications for hypochlorous acid in various industries, such as agriculture, water treatment, and healthcare. This involves developing formulations and delivery systems that maximize efficiency while minimizing environmental impact and resource consumption.

- Recycling and circular economy integration: Implementing recycling processes and circular economy principles in the hypochlorous acid lifecycle. This includes developing methods for recovering and reusing byproducts, implementing take-back programs for containers, and creating closed-loop systems that minimize waste and maximize resource efficiency.

02 Stabilization techniques

Improving the stability of hypochlorous acid solutions to extend shelf life and reduce the need for frequent production. This involves developing advanced formulations, using stabilizing agents, and optimizing storage conditions to maintain efficacy over longer periods.Expand Specific Solutions03 Environmental impact reduction

Minimizing the environmental footprint of hypochlorous acid production and use. This includes developing biodegradable precursors, reducing harmful byproducts, and implementing water-efficient production processes to conserve resources and protect ecosystems.Expand Specific Solutions04 Sustainable packaging solutions

Creating eco-friendly packaging for hypochlorous acid products. This involves using recyclable or biodegradable materials, designing refillable containers, and implementing packaging reduction strategies to minimize waste and promote circular economy principles.Expand Specific Solutions05 Sustainable applications and end-use

Developing new sustainable applications for hypochlorous acid, focusing on replacing more harmful chemicals in various industries. This includes exploring its use in agriculture, water treatment, and green cleaning solutions, promoting its adoption as an environmentally friendly alternative.Expand Specific Solutions

Key Players in Sustainable HOCl Industry

The sustainable hypochlorous acid production market is in a growth phase, driven by increasing demand for eco-friendly disinfectants and water treatment solutions. The global market size is expanding, with projections indicating significant growth in the coming years. Technologically, the field is advancing rapidly, with companies like WIAB WATER INNOVATION AB and Nanjing Chlordun Technology Co., Ltd. leading innovation in production methods. Established players such as Tokuyama Corp. and Kaneka Corp. are investing in R&D to improve efficiency and sustainability. Emerging companies like Symbiosis Technology Co., Ltd. are focusing on novel approaches to address environmental concerns. The competitive landscape is diverse, with a mix of chemical giants and specialized firms driving technological progress and market expansion.

Nanjing Chlordun Technology Co., Ltd.

Technical Solution: Nanjing Chlordun Technology Co., Ltd. has pioneered a sustainable approach to hypochlorous acid production using a novel electrochemical cell design. Their system employs a unique bipolar electrode configuration that allows for simultaneous production of hypochlorous acid and hydrogen gas, maximizing energy efficiency[1]. The company has developed proprietary catalysts that significantly reduce the overpotential required for chlorine evolution, leading to a 25% reduction in electricity consumption compared to conventional methods[2]. Chlordun's process also incorporates an advanced ion exchange system that removes impurities from the feedstock, resulting in higher purity hypochlorous acid and extended equipment lifespan[3]. Additionally, they have implemented a closed-loop water recycling system that reduces water consumption by up to 80%, addressing one of the key sustainability challenges in hypochlorous acid production[4].

Strengths: High energy efficiency, reduced water consumption, and production of valuable hydrogen by-product. Weaknesses: Complexity of the bipolar electrode system may lead to higher maintenance requirements and potential scalability challenges.

Symbiosis Technology Co., Ltd.

Technical Solution: Symbiosis Technology Co., Ltd. has developed a sustainable hypochlorous acid production system based on advanced electrolysis technology. Their process utilizes a unique three-dimensional electrode design that increases the active surface area by up to 300% compared to traditional flat electrodes, resulting in improved reaction kinetics and energy efficiency[1]. The company has implemented a pulsed electric field technique that enhances mass transfer and reduces electrode fouling, leading to a 40% increase in production rate and extended equipment lifespan[2]. Symbiosis' technology also incorporates a smart electrolyte management system that continuously monitors and adjusts salt concentration, pH, and temperature, optimizing production conditions and reducing waste[3]. Additionally, they have developed a novel gas diffusion electrode that enables direct conversion of atmospheric oxygen to hypochlorous acid, eliminating the need for separate chlorine gas production[4].

Strengths: High production efficiency, reduced electrode fouling, and elimination of chlorine gas handling. Weaknesses: Potential complexity in scaling up the three-dimensional electrode design and higher initial investment costs.

Innovative HOCl Synthesis Techniques

Compositions, processes and systems to produce hypochlorous acid

PatentWO2023235881A1

Innovation

- A composition and process using shelf-stable alkali metal or alkaline earth hypochlorite salts combined with acid-form cation exchange resins, where the resin reacts with hypochlorite salts to produce hypochlorous acid, allowing for on-site generation with controlled pH and reduced dissolved solids, utilizing a modular system for efficient production.

Method for Producing Shelf Stable Hypochlorous Acid Solutions

PatentInactiveUS20150119245A1

Innovation

- A method involving the production of hypochlorous acid using high purity water from a combination of softening and reverse osmosis steps, followed by electrolysis with a bipolar membrane, and storage in opaque PET bottles or Nylon/PE bags, which significantly extends the shelf life to 24 months.

Environmental Impact Assessment

The environmental impact assessment of hypochlorous acid (HOCl) production is a critical aspect of ensuring its sustainability. HOCl, while an effective disinfectant, can have significant environmental implications if not managed properly. The production process typically involves electrolysis of salt water, which requires energy input and may result in the release of chlorine gas as a by-product.

One of the primary environmental concerns is the energy consumption associated with HOCl production. Traditional methods often rely on electricity from non-renewable sources, contributing to carbon emissions and climate change. To address this, there is a growing trend towards integrating renewable energy sources, such as solar or wind power, into the production process. This shift not only reduces the carbon footprint but also aligns with global sustainability goals.

Water usage is another crucial factor in the environmental assessment. The production of HOCl requires substantial amounts of water, which can strain local water resources, particularly in water-scarce regions. Implementing water recycling and efficient purification systems can significantly reduce the overall water footprint of the production process.

The potential for chlorine gas emissions during production poses both environmental and health risks. Chlorine gas is a potent air pollutant that can contribute to smog formation and respiratory issues in humans and wildlife. Advanced containment and scrubbing technologies are essential to mitigate these risks and ensure compliance with air quality regulations.

Disposal of by-products and waste from HOCl production also requires careful consideration. Improper disposal can lead to soil and water contamination, affecting ecosystems and potentially entering the food chain. Developing closed-loop systems that minimize waste generation and maximize resource recovery is crucial for sustainable production.

The life cycle assessment of HOCl production must also consider the sourcing of raw materials, particularly salt. Sustainable sourcing practices that minimize environmental disruption and ensure responsible extraction are vital components of an environmentally conscious production process.

As the demand for HOCl grows, particularly in light of its increased use as a disinfectant during global health crises, the importance of sustainable production methods becomes even more pronounced. Innovations in green chemistry and process engineering are paving the way for more environmentally friendly production techniques, such as membrane-based electrolysis systems that reduce energy consumption and improve efficiency.

One of the primary environmental concerns is the energy consumption associated with HOCl production. Traditional methods often rely on electricity from non-renewable sources, contributing to carbon emissions and climate change. To address this, there is a growing trend towards integrating renewable energy sources, such as solar or wind power, into the production process. This shift not only reduces the carbon footprint but also aligns with global sustainability goals.

Water usage is another crucial factor in the environmental assessment. The production of HOCl requires substantial amounts of water, which can strain local water resources, particularly in water-scarce regions. Implementing water recycling and efficient purification systems can significantly reduce the overall water footprint of the production process.

The potential for chlorine gas emissions during production poses both environmental and health risks. Chlorine gas is a potent air pollutant that can contribute to smog formation and respiratory issues in humans and wildlife. Advanced containment and scrubbing technologies are essential to mitigate these risks and ensure compliance with air quality regulations.

Disposal of by-products and waste from HOCl production also requires careful consideration. Improper disposal can lead to soil and water contamination, affecting ecosystems and potentially entering the food chain. Developing closed-loop systems that minimize waste generation and maximize resource recovery is crucial for sustainable production.

The life cycle assessment of HOCl production must also consider the sourcing of raw materials, particularly salt. Sustainable sourcing practices that minimize environmental disruption and ensure responsible extraction are vital components of an environmentally conscious production process.

As the demand for HOCl grows, particularly in light of its increased use as a disinfectant during global health crises, the importance of sustainable production methods becomes even more pronounced. Innovations in green chemistry and process engineering are paving the way for more environmentally friendly production techniques, such as membrane-based electrolysis systems that reduce energy consumption and improve efficiency.

Regulatory Framework for HOCl Manufacturing

The regulatory framework for hypochlorous acid (HOCl) manufacturing is a complex and evolving landscape that significantly impacts the production, distribution, and use of this versatile disinfectant. In the United States, the Environmental Protection Agency (EPA) plays a crucial role in regulating HOCl under the Federal Insecticide, Fungicide, and Rodenticide Act (FIFRA). This act requires manufacturers to register their HOCl products and provide extensive data on safety, efficacy, and environmental impact.

The Food and Drug Administration (FDA) also has oversight in certain applications, particularly when HOCl is used in food processing or medical devices. The FDA's regulations focus on ensuring the safety and effectiveness of HOCl in these specific contexts, often requiring manufacturers to adhere to Good Manufacturing Practices (GMP) and obtain premarket approval for certain uses.

Internationally, regulatory approaches to HOCl vary. The European Union, for instance, regulates HOCl under the Biocidal Products Regulation (BPR), which requires a thorough assessment of active substances and products before they can be placed on the market. This process includes evaluating the environmental and health risks associated with HOCl production and use.

In recent years, there has been a growing emphasis on sustainable production methods for HOCl. Regulatory bodies are increasingly considering the environmental impact of manufacturing processes, encouraging the adoption of greener technologies. This shift has led to the development of new guidelines and standards for sustainable HOCl production, focusing on reducing energy consumption, minimizing waste, and promoting the use of renewable resources.

The regulatory framework also addresses the quality control and stability of HOCl products. Given the compound's tendency to degrade over time, regulations often specify storage conditions, shelf life, and labeling requirements. Manufacturers must demonstrate the consistency and reliability of their production processes to meet these regulatory standards.

As the applications for HOCl continue to expand, particularly in healthcare and sanitation, regulatory bodies are adapting their frameworks to address new use cases. This includes developing specific guidelines for on-site generation of HOCl, which presents unique regulatory challenges due to the variability in production conditions and the need for real-time quality assurance.

The global nature of HOCl production and distribution necessitates harmonization efforts between different regulatory regimes. International organizations such as the World Health Organization (WHO) and the Codex Alimentarius Commission provide guidance to help align regulatory approaches across countries, facilitating global trade while ensuring consistent safety standards.

The Food and Drug Administration (FDA) also has oversight in certain applications, particularly when HOCl is used in food processing or medical devices. The FDA's regulations focus on ensuring the safety and effectiveness of HOCl in these specific contexts, often requiring manufacturers to adhere to Good Manufacturing Practices (GMP) and obtain premarket approval for certain uses.

Internationally, regulatory approaches to HOCl vary. The European Union, for instance, regulates HOCl under the Biocidal Products Regulation (BPR), which requires a thorough assessment of active substances and products before they can be placed on the market. This process includes evaluating the environmental and health risks associated with HOCl production and use.

In recent years, there has been a growing emphasis on sustainable production methods for HOCl. Regulatory bodies are increasingly considering the environmental impact of manufacturing processes, encouraging the adoption of greener technologies. This shift has led to the development of new guidelines and standards for sustainable HOCl production, focusing on reducing energy consumption, minimizing waste, and promoting the use of renewable resources.

The regulatory framework also addresses the quality control and stability of HOCl products. Given the compound's tendency to degrade over time, regulations often specify storage conditions, shelf life, and labeling requirements. Manufacturers must demonstrate the consistency and reliability of their production processes to meet these regulatory standards.

As the applications for HOCl continue to expand, particularly in healthcare and sanitation, regulatory bodies are adapting their frameworks to address new use cases. This includes developing specific guidelines for on-site generation of HOCl, which presents unique regulatory challenges due to the variability in production conditions and the need for real-time quality assurance.

The global nature of HOCl production and distribution necessitates harmonization efforts between different regulatory regimes. International organizations such as the World Health Organization (WHO) and the Codex Alimentarius Commission provide guidance to help align regulatory approaches across countries, facilitating global trade while ensuring consistent safety standards.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!