The Role of Hypochlorous Acid in Sustainable Supply Chain Models

AUG 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

HOCL Background & Objectives

Hypochlorous acid (HOCl) has emerged as a significant player in sustainable supply chain models, offering a unique combination of efficacy, safety, and environmental friendliness. This naturally occurring compound, found in the human immune system, has gained attention for its potential to revolutionize various industries, particularly in disinfection and sanitation processes.

The development of HOCl technology can be traced back to the early 20th century, with its initial applications in water treatment and wound care. However, recent advancements in production methods and a growing emphasis on sustainability have propelled HOCl into the spotlight as a versatile solution for modern supply chain challenges.

In the context of sustainable supply chain models, HOCl addresses several key objectives. Primarily, it aims to reduce the environmental impact of traditional chemical disinfectants and sanitizers, which often contain harsh compounds that can harm ecosystems and human health. HOCl breaks down into simple salt and water, leaving no harmful residues or by-products.

Another critical objective is to enhance the overall efficiency and safety of supply chain operations. HOCl's rapid action against a broad spectrum of pathogens, including bacteria, viruses, and fungi, makes it an ideal candidate for maintaining hygiene standards in various stages of the supply chain, from production facilities to transportation and storage.

The technology behind HOCl production has evolved significantly, with current methods focusing on electrolysis of salt water to create a stable and effective solution. This process aligns with sustainable practices by utilizing minimal resources and producing a product with a lower carbon footprint compared to traditional chemical alternatives.

As industries worldwide seek to adopt more sustainable practices, HOCl presents an opportunity to address multiple challenges simultaneously. Its potential applications extend beyond simple disinfection, encompassing areas such as food safety, water treatment, and even agricultural practices, where it can reduce reliance on harmful pesticides.

The objectives of integrating HOCl into sustainable supply chain models are multifaceted. They include improving product safety and quality, reducing environmental impact, enhancing worker safety, and potentially lowering operational costs through more efficient and versatile sanitation processes. Additionally, the adoption of HOCl technology aligns with growing consumer demand for eco-friendly products and practices, potentially offering a competitive advantage in the marketplace.

As research and development in this field continue, the role of HOCl in sustainable supply chain models is expected to expand. Future objectives may include developing more efficient production methods, exploring new applications across different industries, and establishing HOCl as a standard component in global sustainability initiatives.

The development of HOCl technology can be traced back to the early 20th century, with its initial applications in water treatment and wound care. However, recent advancements in production methods and a growing emphasis on sustainability have propelled HOCl into the spotlight as a versatile solution for modern supply chain challenges.

In the context of sustainable supply chain models, HOCl addresses several key objectives. Primarily, it aims to reduce the environmental impact of traditional chemical disinfectants and sanitizers, which often contain harsh compounds that can harm ecosystems and human health. HOCl breaks down into simple salt and water, leaving no harmful residues or by-products.

Another critical objective is to enhance the overall efficiency and safety of supply chain operations. HOCl's rapid action against a broad spectrum of pathogens, including bacteria, viruses, and fungi, makes it an ideal candidate for maintaining hygiene standards in various stages of the supply chain, from production facilities to transportation and storage.

The technology behind HOCl production has evolved significantly, with current methods focusing on electrolysis of salt water to create a stable and effective solution. This process aligns with sustainable practices by utilizing minimal resources and producing a product with a lower carbon footprint compared to traditional chemical alternatives.

As industries worldwide seek to adopt more sustainable practices, HOCl presents an opportunity to address multiple challenges simultaneously. Its potential applications extend beyond simple disinfection, encompassing areas such as food safety, water treatment, and even agricultural practices, where it can reduce reliance on harmful pesticides.

The objectives of integrating HOCl into sustainable supply chain models are multifaceted. They include improving product safety and quality, reducing environmental impact, enhancing worker safety, and potentially lowering operational costs through more efficient and versatile sanitation processes. Additionally, the adoption of HOCl technology aligns with growing consumer demand for eco-friendly products and practices, potentially offering a competitive advantage in the marketplace.

As research and development in this field continue, the role of HOCl in sustainable supply chain models is expected to expand. Future objectives may include developing more efficient production methods, exploring new applications across different industries, and establishing HOCl as a standard component in global sustainability initiatives.

Market Demand Analysis

The market demand for hypochlorous acid (HOCl) in sustainable supply chain models has been steadily increasing due to its versatile applications and eco-friendly properties. As industries and consumers become more environmentally conscious, the adoption of HOCl as a sustainable alternative to traditional chemicals is gaining momentum across various sectors.

In the food and beverage industry, there is a growing demand for HOCl as a safe and effective sanitizer for food processing equipment, surfaces, and packaging materials. Its ability to eliminate pathogens without leaving harmful residues aligns with the industry's focus on food safety and sustainability. The agricultural sector is also showing increased interest in HOCl for crop protection and post-harvest treatment, as it offers a chemical-free solution that meets organic farming standards.

The healthcare industry represents another significant market for HOCl in sustainable supply chains. Hospitals, clinics, and long-term care facilities are adopting HOCl-based disinfection systems to maintain high hygiene standards while reducing their environmental footprint. The COVID-19 pandemic has further accelerated this trend, highlighting the importance of effective yet sustainable disinfection methods.

Water treatment is emerging as a key application area for HOCl in sustainable supply chains. Municipal water treatment plants and industrial facilities are exploring HOCl as an alternative to chlorine-based disinfectants, driven by its lower environmental impact and reduced formation of harmful byproducts. This shift is particularly notable in regions facing water scarcity and stringent environmental regulations.

The personal care and cosmetics industry is also contributing to the market demand for HOCl. Consumers are increasingly seeking natural and gentle skincare products, leading to the incorporation of HOCl in various formulations due to its antimicrobial properties and skin-friendly nature.

As sustainability becomes a core focus in supply chain management, the demand for HOCl is expected to grow across multiple industries. Companies are recognizing the potential of HOCl to reduce their carbon footprint, minimize chemical waste, and improve overall operational efficiency. This trend is likely to drive innovation in HOCl production methods and application technologies, further expanding its market potential.

The global push towards circular economy models is also influencing the adoption of HOCl in supply chains. Its biodegradability and non-toxic nature make it an attractive option for companies aiming to implement closed-loop systems and reduce their environmental impact throughout the product lifecycle.

In the food and beverage industry, there is a growing demand for HOCl as a safe and effective sanitizer for food processing equipment, surfaces, and packaging materials. Its ability to eliminate pathogens without leaving harmful residues aligns with the industry's focus on food safety and sustainability. The agricultural sector is also showing increased interest in HOCl for crop protection and post-harvest treatment, as it offers a chemical-free solution that meets organic farming standards.

The healthcare industry represents another significant market for HOCl in sustainable supply chains. Hospitals, clinics, and long-term care facilities are adopting HOCl-based disinfection systems to maintain high hygiene standards while reducing their environmental footprint. The COVID-19 pandemic has further accelerated this trend, highlighting the importance of effective yet sustainable disinfection methods.

Water treatment is emerging as a key application area for HOCl in sustainable supply chains. Municipal water treatment plants and industrial facilities are exploring HOCl as an alternative to chlorine-based disinfectants, driven by its lower environmental impact and reduced formation of harmful byproducts. This shift is particularly notable in regions facing water scarcity and stringent environmental regulations.

The personal care and cosmetics industry is also contributing to the market demand for HOCl. Consumers are increasingly seeking natural and gentle skincare products, leading to the incorporation of HOCl in various formulations due to its antimicrobial properties and skin-friendly nature.

As sustainability becomes a core focus in supply chain management, the demand for HOCl is expected to grow across multiple industries. Companies are recognizing the potential of HOCl to reduce their carbon footprint, minimize chemical waste, and improve overall operational efficiency. This trend is likely to drive innovation in HOCl production methods and application technologies, further expanding its market potential.

The global push towards circular economy models is also influencing the adoption of HOCl in supply chains. Its biodegradability and non-toxic nature make it an attractive option for companies aiming to implement closed-loop systems and reduce their environmental impact throughout the product lifecycle.

HOCL Tech Status & Challenges

Hypochlorous acid (HOCl) has gained significant attention in recent years due to its potential role in sustainable supply chain models. The current technological status of HOCl production and application presents both promising advancements and notable challenges. One of the primary developments in HOCl technology is the improvement in production methods, with electrochemical activation emerging as a more efficient and environmentally friendly process compared to traditional chemical synthesis.

The stability of HOCl solutions has been a persistent challenge, as the compound tends to degrade over time, reducing its effectiveness. However, recent innovations in stabilization techniques, such as the use of specific buffer systems and packaging materials, have extended the shelf life of HOCl products. This improvement has significant implications for supply chain logistics, allowing for broader distribution and longer storage periods.

In terms of application, HOCl has demonstrated remarkable versatility across various industries. Its powerful antimicrobial properties make it an excellent alternative to traditional disinfectants, particularly in healthcare, food processing, and water treatment sectors. The non-toxic nature of HOCl at appropriate concentrations has positioned it as a sustainable option in these applications, aligning with growing consumer demand for eco-friendly products.

Despite these advancements, several challenges remain in the widespread adoption of HOCl in sustainable supply chain models. One significant hurdle is the lack of standardization in production and quality control processes. This variability can lead to inconsistent product efficacy and hinder regulatory approval in certain markets. Additionally, the cost of production, while decreasing, still poses a barrier to large-scale implementation in some industries.

Another challenge lies in the education and awareness of HOCl's benefits and proper usage among potential users and consumers. Many are unfamiliar with its properties and advantages over conventional disinfectants, which can slow market penetration and integration into existing supply chains. This knowledge gap extends to regulatory bodies, potentially leading to delays in approval processes and standardization efforts.

The geographical distribution of HOCl technology development shows concentration in developed countries, particularly in North America, Europe, and parts of Asia. This uneven distribution presents challenges in global adoption and may contribute to disparities in access to sustainable disinfection solutions. Efforts to transfer technology and knowledge to developing regions are crucial for realizing the full potential of HOCl in global sustainable supply chain models.

The stability of HOCl solutions has been a persistent challenge, as the compound tends to degrade over time, reducing its effectiveness. However, recent innovations in stabilization techniques, such as the use of specific buffer systems and packaging materials, have extended the shelf life of HOCl products. This improvement has significant implications for supply chain logistics, allowing for broader distribution and longer storage periods.

In terms of application, HOCl has demonstrated remarkable versatility across various industries. Its powerful antimicrobial properties make it an excellent alternative to traditional disinfectants, particularly in healthcare, food processing, and water treatment sectors. The non-toxic nature of HOCl at appropriate concentrations has positioned it as a sustainable option in these applications, aligning with growing consumer demand for eco-friendly products.

Despite these advancements, several challenges remain in the widespread adoption of HOCl in sustainable supply chain models. One significant hurdle is the lack of standardization in production and quality control processes. This variability can lead to inconsistent product efficacy and hinder regulatory approval in certain markets. Additionally, the cost of production, while decreasing, still poses a barrier to large-scale implementation in some industries.

Another challenge lies in the education and awareness of HOCl's benefits and proper usage among potential users and consumers. Many are unfamiliar with its properties and advantages over conventional disinfectants, which can slow market penetration and integration into existing supply chains. This knowledge gap extends to regulatory bodies, potentially leading to delays in approval processes and standardization efforts.

The geographical distribution of HOCl technology development shows concentration in developed countries, particularly in North America, Europe, and parts of Asia. This uneven distribution presents challenges in global adoption and may contribute to disparities in access to sustainable disinfection solutions. Efforts to transfer technology and knowledge to developing regions are crucial for realizing the full potential of HOCl in global sustainable supply chain models.

Current HOCL Solutions

01 Production methods of hypochlorous acid

Various methods are employed to produce hypochlorous acid, including electrolysis of salt solutions, chemical reactions involving chlorine and water, and the use of specialized equipment for on-site generation. These methods aim to create stable and effective hypochlorous acid solutions for different applications.- Production methods of hypochlorous acid: Various methods are employed to produce hypochlorous acid, including electrolysis of salt solutions, chemical reactions involving chlorine and water, and controlled mixing of precursor chemicals. These production methods aim to create stable and effective hypochlorous acid solutions for different applications.

- Antimicrobial applications of hypochlorous acid: Hypochlorous acid is widely used as an antimicrobial agent in various fields, including healthcare, food processing, and water treatment. Its effectiveness against a broad spectrum of pathogens, combined with its low toxicity to humans, makes it a valuable disinfectant and sanitizer.

- Stabilization and formulation of hypochlorous acid solutions: Techniques for stabilizing hypochlorous acid solutions are crucial for maintaining their efficacy over time. This includes pH adjustment, addition of stabilizing agents, and specialized packaging to prevent degradation. Formulation strategies aim to enhance shelf life and preserve the active properties of hypochlorous acid.

- Medical and therapeutic uses of hypochlorous acid: Hypochlorous acid finds applications in various medical and therapeutic contexts, including wound care, eye care, and respiratory treatments. Its natural occurrence in the human immune system and low cytotoxicity make it suitable for these sensitive applications.

- Environmental and industrial applications of hypochlorous acid: Hypochlorous acid is utilized in environmental remediation, industrial cleaning, and agriculture. Its eco-friendly nature and effectiveness in removing contaminants make it a preferred choice for various industrial processes and environmental management applications.

02 Antimicrobial applications of hypochlorous acid

Hypochlorous acid is widely used as an antimicrobial agent in various fields, including healthcare, food processing, and water treatment. Its effectiveness against a broad spectrum of pathogens, combined with its low toxicity to humans, makes it a valuable disinfectant and sanitizer.Expand Specific Solutions03 Stabilization techniques for hypochlorous acid solutions

Researchers have developed various methods to stabilize hypochlorous acid solutions, extending their shelf life and maintaining their efficacy. These techniques may involve pH adjustment, addition of stabilizing agents, or specialized packaging to prevent degradation and ensure long-term stability.Expand Specific Solutions04 Medical and therapeutic uses of hypochlorous acid

Hypochlorous acid has found applications in medical treatments and therapies, including wound care, eye care, and respiratory treatments. Its ability to effectively kill pathogens while being gentle on human tissues makes it suitable for various medical applications.Expand Specific Solutions05 Environmental and industrial applications of hypochlorous acid

Hypochlorous acid is utilized in environmental remediation, industrial cleaning, and agricultural applications. Its eco-friendly nature and effectiveness in removing contaminants make it a preferred choice for various industrial processes and environmental protection efforts.Expand Specific Solutions

Key Industry Players

The market for hypochlorous acid in sustainable supply chain models is in a growth phase, driven by increasing demand for eco-friendly disinfection solutions. The global market size is expanding, with projections indicating significant growth potential in various sectors, including healthcare, agriculture, and water treatment. Technologically, the field is advancing rapidly, with companies like WIAB WATER INNOVATION AB, Aquaox, Inc., and ANNIHILARE MEDICAL SYSTEMS, INC. leading innovation in production methods and applications. Academic institutions such as Harbin University of Science & Technology and Southwest Jiaotong University are contributing to research and development, enhancing the technology's efficiency and sustainability. The competitive landscape is diverse, with both specialized firms and larger conglomerates like Toshiba Corp. and Halliburton Energy Services, Inc. exploring applications in their respective industries.

Aquaox, Inc.

Technical Solution: Aquaox has pioneered a sustainable supply chain model centered around their patented electrochemical activation (ECA) technology for producing hypochlorous acid. Their system utilizes a proprietary electrolytic cell design that allows for the efficient production of HOCl using only salt, water, and electricity[4]. The company's approach focuses on decentralized production, enabling customers to generate HOCl on-demand at the point of use. This model eliminates the need for traditional chemical transportation and storage, significantly reducing the environmental impact of disinfectant supply chains[5]. Aquaox's technology produces a highly stable form of HOCl with a pH range of 6.5-7.0, ensuring optimal efficacy and safety for various applications. The company has also developed smart monitoring systems that optimize production based on usage patterns, further enhancing the sustainability of their solution[6].

Strengths: Decentralized production model reduces supply chain complexity; smart monitoring systems optimize resource use; stable HOCl formulation enhances efficacy. Weaknesses: Reliance on electricity may limit applicability in some settings; initial investment in equipment may be substantial.

Dyson Technology Ltd.

Technical Solution: Dyson Technology has applied its expertise in fluid dynamics and electromechanical systems to develop an innovative approach to hypochlorous acid production and distribution within sustainable supply chain models. Their system utilizes a compact, modular design that can be easily integrated into various environments, from healthcare facilities to industrial settings[10]. Dyson's HOCl generator employs advanced electrochemical cells with proprietary electrode materials that enhance the efficiency of the electrolysis process, reducing energy consumption by up to 30% compared to conventional systems[11]. The company has also developed smart dispensing technology that precisely controls HOCl application, minimizing waste and optimizing disinfection efficacy. Dyson's solution includes a cloud-based monitoring system that tracks HOCl production, usage, and environmental impact, providing real-time data for supply chain optimization[12].

Strengths: Modular design allows for flexible deployment; energy-efficient electrolysis process; smart dispensing and monitoring systems optimize usage. Weaknesses: May have a higher upfront cost compared to traditional disinfection methods; requires reliable internet connectivity for full functionality of cloud-based features.

HOCL Core Innovations

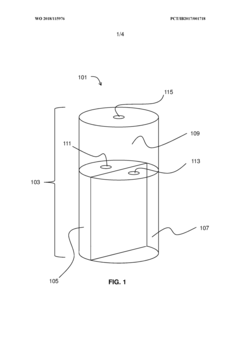

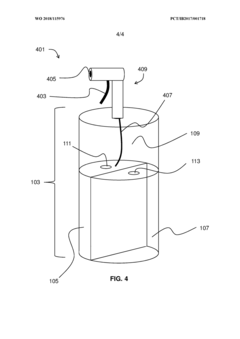

Multi-chambered storage and delivery container

PatentWO2018115976A1

Innovation

- A multi-chambered container system that separates and stabilizes the components for producing hypochlorous acid, using one-way valves and buffering agents to maintain a stable pH and prevent air exposure, allowing for on-site preparation and long-term storage of hypochlorous acid compositions, which are substantially free of chloride and metal ions.

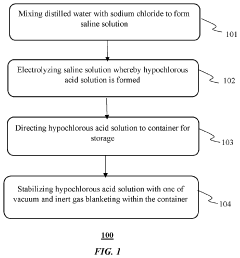

Method for stabilization of hypochlorous acid solution

PatentInactiveUS20200080208A1

Innovation

- A method involving the electrolysis of a saline solution using a uniflow membrane to produce hypochlorous acid, followed by storage in containers with vacuum or inert gas blanketing and specific gas and moisture transmission rates to maintain stability, and optionally coating with Titanium Dioxide.

Environmental Impact

The integration of hypochlorous acid (HOCl) into sustainable supply chain models presents significant environmental implications. As a powerful yet eco-friendly disinfectant, HOCl offers a promising alternative to traditional chemical sanitizers, potentially reducing the environmental footprint of various industries.

HOCl's production process is relatively simple and energy-efficient, requiring only water, salt, and electricity. This minimal resource consumption contributes to lower carbon emissions compared to the manufacture of conventional disinfectants. Furthermore, the raw materials used in HOCl production are abundant and renewable, aligning with principles of sustainable resource management.

One of the most notable environmental benefits of HOCl is its rapid biodegradability. Unlike many chemical disinfectants that persist in the environment, HOCl breaks down quickly into harmless components: water and salt. This characteristic significantly reduces the risk of water pollution and soil contamination, making it an ideal choice for industries with stringent environmental regulations.

In agricultural supply chains, the use of HOCl as a sanitizer for crops and equipment can lead to a reduction in harmful pesticide use. This shift not only protects biodiversity but also promotes soil health by minimizing chemical residues. The food industry can benefit from HOCl's application in processing and packaging, potentially decreasing water consumption and chemical waste associated with traditional cleaning methods.

The transportation sector, a critical component of supply chains, can leverage HOCl for vehicle and container sanitization. This application could reduce the need for harsh chemicals and minimize the release of volatile organic compounds (VOCs) into the atmosphere. Additionally, the use of HOCl in water treatment facilities within supply chain operations can enhance water quality while reducing the reliance on chlorine and other potentially harmful disinfectants.

However, the environmental impact of HOCl integration is not without challenges. The production of HOCl requires electricity, and the environmental benefits can be maximized only when this energy comes from renewable sources. Moreover, the widespread adoption of HOCl in supply chains necessitates the development of new infrastructure and processes, which may have short-term environmental costs.

In conclusion, the incorporation of hypochlorous acid into sustainable supply chain models offers substantial environmental advantages. Its eco-friendly properties, from production to disposal, align well with circular economy principles and can contribute significantly to reducing the overall environmental impact of global supply chains. As industries continue to prioritize sustainability, HOCl stands out as a promising solution for balancing effective sanitization with environmental stewardship.

HOCl's production process is relatively simple and energy-efficient, requiring only water, salt, and electricity. This minimal resource consumption contributes to lower carbon emissions compared to the manufacture of conventional disinfectants. Furthermore, the raw materials used in HOCl production are abundant and renewable, aligning with principles of sustainable resource management.

One of the most notable environmental benefits of HOCl is its rapid biodegradability. Unlike many chemical disinfectants that persist in the environment, HOCl breaks down quickly into harmless components: water and salt. This characteristic significantly reduces the risk of water pollution and soil contamination, making it an ideal choice for industries with stringent environmental regulations.

In agricultural supply chains, the use of HOCl as a sanitizer for crops and equipment can lead to a reduction in harmful pesticide use. This shift not only protects biodiversity but also promotes soil health by minimizing chemical residues. The food industry can benefit from HOCl's application in processing and packaging, potentially decreasing water consumption and chemical waste associated with traditional cleaning methods.

The transportation sector, a critical component of supply chains, can leverage HOCl for vehicle and container sanitization. This application could reduce the need for harsh chemicals and minimize the release of volatile organic compounds (VOCs) into the atmosphere. Additionally, the use of HOCl in water treatment facilities within supply chain operations can enhance water quality while reducing the reliance on chlorine and other potentially harmful disinfectants.

However, the environmental impact of HOCl integration is not without challenges. The production of HOCl requires electricity, and the environmental benefits can be maximized only when this energy comes from renewable sources. Moreover, the widespread adoption of HOCl in supply chains necessitates the development of new infrastructure and processes, which may have short-term environmental costs.

In conclusion, the incorporation of hypochlorous acid into sustainable supply chain models offers substantial environmental advantages. Its eco-friendly properties, from production to disposal, align well with circular economy principles and can contribute significantly to reducing the overall environmental impact of global supply chains. As industries continue to prioritize sustainability, HOCl stands out as a promising solution for balancing effective sanitization with environmental stewardship.

Regulatory Framework

The regulatory framework surrounding the use of hypochlorous acid in sustainable supply chain models is complex and multifaceted, involving various governmental agencies and international bodies. At the forefront, the Environmental Protection Agency (EPA) plays a crucial role in regulating the production, distribution, and application of hypochlorous acid in the United States. The EPA has classified hypochlorous acid as a pesticide, which subjects it to stringent registration and labeling requirements under the Federal Insecticide, Fungicide, and Rodenticide Act (FIFRA).

Internationally, the European Chemicals Agency (ECHA) oversees the regulation of hypochlorous acid within the European Union. Under the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation, manufacturers and importers must register hypochlorous acid and provide detailed safety information. The ECHA also assesses the potential risks associated with its use and may impose restrictions or authorizations as necessary.

In the context of sustainable supply chain models, the Food and Drug Administration (FDA) in the United States has approved hypochlorous acid for use in food processing and as an antimicrobial agent in certain applications. This approval has significant implications for the food industry's supply chains, allowing for more sustainable practices in food safety and preservation.

The Occupational Safety and Health Administration (OSHA) sets standards for the safe handling and use of hypochlorous acid in workplace environments. These regulations are particularly relevant for manufacturing facilities and distribution centers within the supply chain that may handle or produce hypochlorous acid-based products.

Global harmonization efforts, such as the Globally Harmonized System of Classification and Labelling of Chemicals (GHS), have also impacted the regulatory landscape for hypochlorous acid. This system aims to standardize the classification and communication of chemical hazards across different countries, facilitating international trade and improving safety standards throughout the supply chain.

The World Health Organization (WHO) and the Food and Agriculture Organization (FAO) have jointly established guidelines for the use of hypochlorous acid in water treatment and food production. These guidelines influence national policies and regulations, particularly in developing countries seeking to implement sustainable supply chain practices.

As sustainability becomes increasingly important in supply chain management, regulatory bodies are adapting their frameworks to encourage the use of environmentally friendly substances like hypochlorous acid. For instance, some jurisdictions offer incentives or expedited approval processes for products that demonstrate improved environmental profiles compared to traditional alternatives.

Internationally, the European Chemicals Agency (ECHA) oversees the regulation of hypochlorous acid within the European Union. Under the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation, manufacturers and importers must register hypochlorous acid and provide detailed safety information. The ECHA also assesses the potential risks associated with its use and may impose restrictions or authorizations as necessary.

In the context of sustainable supply chain models, the Food and Drug Administration (FDA) in the United States has approved hypochlorous acid for use in food processing and as an antimicrobial agent in certain applications. This approval has significant implications for the food industry's supply chains, allowing for more sustainable practices in food safety and preservation.

The Occupational Safety and Health Administration (OSHA) sets standards for the safe handling and use of hypochlorous acid in workplace environments. These regulations are particularly relevant for manufacturing facilities and distribution centers within the supply chain that may handle or produce hypochlorous acid-based products.

Global harmonization efforts, such as the Globally Harmonized System of Classification and Labelling of Chemicals (GHS), have also impacted the regulatory landscape for hypochlorous acid. This system aims to standardize the classification and communication of chemical hazards across different countries, facilitating international trade and improving safety standards throughout the supply chain.

The World Health Organization (WHO) and the Food and Agriculture Organization (FAO) have jointly established guidelines for the use of hypochlorous acid in water treatment and food production. These guidelines influence national policies and regulations, particularly in developing countries seeking to implement sustainable supply chain practices.

As sustainability becomes increasingly important in supply chain management, regulatory bodies are adapting their frameworks to encourage the use of environmentally friendly substances like hypochlorous acid. For instance, some jurisdictions offer incentives or expedited approval processes for products that demonstrate improved environmental profiles compared to traditional alternatives.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!