The Influence of Hypochlorous Acid on Bacterial Resistance

AUG 4, 20258 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

HOCl and Bacterial Resistance: Background and Objectives

Hypochlorous acid (HOCl) has emerged as a significant focus in the field of microbiology and antimicrobial research. This naturally occurring molecule, produced by the human immune system, has garnered attention for its potential in combating bacterial resistance. The evolution of HOCl as an antimicrobial agent traces back to its discovery in the early 19th century, with its role in the immune system elucidated in the late 20th century.

The development trajectory of HOCl technology has been marked by significant milestones. Initially recognized for its disinfectant properties, HOCl has transitioned from industrial applications to healthcare and consumer products. Recent advancements in stabilization techniques have expanded its potential uses, addressing previous limitations related to shelf-life and efficacy.

Current research aims to fully understand the mechanisms by which HOCl affects bacterial resistance. The primary objectives include elucidating its mode of action against various bacterial strains, particularly those exhibiting antibiotic resistance. Researchers are investigating HOCl's potential to disrupt biofilms, neutralize bacterial toxins, and modulate the host immune response.

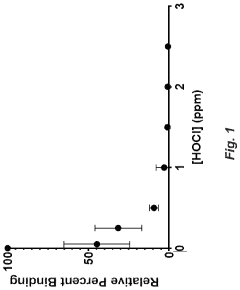

Another critical goal is to explore HOCl's role in preventing the development of bacterial resistance. Unlike traditional antibiotics, HOCl's broad-spectrum activity and rapid action may present a lower risk of resistance development. Studies are underway to determine optimal concentrations and application methods to maximize efficacy while minimizing potential adverse effects.

The technological landscape surrounding HOCl is evolving rapidly. Innovations in production methods, such as electrochemical activation, are enhancing the scalability and cost-effectiveness of HOCl solutions. Concurrently, research is focused on developing novel delivery systems to maintain HOCl stability and ensure targeted application in various medical and industrial settings.

As antibiotic resistance continues to pose a global health threat, the exploration of alternative antimicrobial strategies has become imperative. HOCl represents a promising avenue in this pursuit, with its potential to complement or even replace certain conventional antibiotics in specific applications. The ongoing research aims to position HOCl as a key player in the arsenal against bacterial resistance, potentially revolutionizing infection control strategies across multiple sectors.

The development trajectory of HOCl technology has been marked by significant milestones. Initially recognized for its disinfectant properties, HOCl has transitioned from industrial applications to healthcare and consumer products. Recent advancements in stabilization techniques have expanded its potential uses, addressing previous limitations related to shelf-life and efficacy.

Current research aims to fully understand the mechanisms by which HOCl affects bacterial resistance. The primary objectives include elucidating its mode of action against various bacterial strains, particularly those exhibiting antibiotic resistance. Researchers are investigating HOCl's potential to disrupt biofilms, neutralize bacterial toxins, and modulate the host immune response.

Another critical goal is to explore HOCl's role in preventing the development of bacterial resistance. Unlike traditional antibiotics, HOCl's broad-spectrum activity and rapid action may present a lower risk of resistance development. Studies are underway to determine optimal concentrations and application methods to maximize efficacy while minimizing potential adverse effects.

The technological landscape surrounding HOCl is evolving rapidly. Innovations in production methods, such as electrochemical activation, are enhancing the scalability and cost-effectiveness of HOCl solutions. Concurrently, research is focused on developing novel delivery systems to maintain HOCl stability and ensure targeted application in various medical and industrial settings.

As antibiotic resistance continues to pose a global health threat, the exploration of alternative antimicrobial strategies has become imperative. HOCl represents a promising avenue in this pursuit, with its potential to complement or even replace certain conventional antibiotics in specific applications. The ongoing research aims to position HOCl as a key player in the arsenal against bacterial resistance, potentially revolutionizing infection control strategies across multiple sectors.

Market Analysis for HOCl-based Antimicrobial Solutions

The market for HOCl-based antimicrobial solutions has experienced significant growth in recent years, driven by increasing awareness of the importance of effective disinfection and the rise of antibiotic-resistant bacteria. The global market for these solutions is expected to continue expanding, with a compound annual growth rate projected to remain strong through the next decade.

Healthcare facilities represent a major segment of the market, as hospitals and clinics seek more effective and safer alternatives to traditional disinfectants. The COVID-19 pandemic has further accelerated demand in this sector, with heightened focus on infection control measures. Additionally, the food and beverage industry has emerged as a key market, utilizing HOCl solutions for sanitization in production facilities and food processing plants.

Consumer demand for HOCl-based products has also surged, particularly in household cleaning and personal care applications. This trend is driven by growing consumer preference for natural, non-toxic disinfectants that are safe for use around children and pets. The agriculture sector presents another significant market opportunity, with HOCl solutions being increasingly adopted for crop protection and livestock management.

Geographically, North America and Europe currently dominate the market, owing to stringent regulations on disinfection practices and higher awareness of antimicrobial resistance issues. However, the Asia-Pacific region is expected to witness the fastest growth, fueled by rapid industrialization, improving healthcare infrastructure, and increasing disposable incomes.

Key market drivers include the growing concern over hospital-acquired infections, the rise of antibiotic-resistant superbugs, and the shift towards environmentally friendly disinfection methods. The non-toxic nature of HOCl and its broad-spectrum antimicrobial efficacy position it favorably against traditional chemical disinfectants.

Challenges in the market include the relatively short shelf life of HOCl solutions and the need for specialized equipment for on-site generation. However, ongoing research and development efforts are addressing these issues, with innovations in stabilization techniques and portable generation systems.

The competitive landscape is characterized by a mix of established chemical companies and innovative startups. Key players are focusing on product development, strategic partnerships, and expanding their distribution networks to gain market share. As the technology matures and production costs decrease, the market is likely to see increased competition and potential consolidation.

Healthcare facilities represent a major segment of the market, as hospitals and clinics seek more effective and safer alternatives to traditional disinfectants. The COVID-19 pandemic has further accelerated demand in this sector, with heightened focus on infection control measures. Additionally, the food and beverage industry has emerged as a key market, utilizing HOCl solutions for sanitization in production facilities and food processing plants.

Consumer demand for HOCl-based products has also surged, particularly in household cleaning and personal care applications. This trend is driven by growing consumer preference for natural, non-toxic disinfectants that are safe for use around children and pets. The agriculture sector presents another significant market opportunity, with HOCl solutions being increasingly adopted for crop protection and livestock management.

Geographically, North America and Europe currently dominate the market, owing to stringent regulations on disinfection practices and higher awareness of antimicrobial resistance issues. However, the Asia-Pacific region is expected to witness the fastest growth, fueled by rapid industrialization, improving healthcare infrastructure, and increasing disposable incomes.

Key market drivers include the growing concern over hospital-acquired infections, the rise of antibiotic-resistant superbugs, and the shift towards environmentally friendly disinfection methods. The non-toxic nature of HOCl and its broad-spectrum antimicrobial efficacy position it favorably against traditional chemical disinfectants.

Challenges in the market include the relatively short shelf life of HOCl solutions and the need for specialized equipment for on-site generation. However, ongoing research and development efforts are addressing these issues, with innovations in stabilization techniques and portable generation systems.

The competitive landscape is characterized by a mix of established chemical companies and innovative startups. Key players are focusing on product development, strategic partnerships, and expanding their distribution networks to gain market share. As the technology matures and production costs decrease, the market is likely to see increased competition and potential consolidation.

Current Challenges in HOCl Antimicrobial Efficacy

Despite the proven efficacy of hypochlorous acid (HOCl) as a potent antimicrobial agent, several challenges persist in its widespread adoption and optimal utilization. One of the primary concerns is the stability of HOCl solutions. The compound is known to be highly reactive and can degrade rapidly, especially when exposed to light, heat, or organic matter. This instability poses significant challenges in storage, transportation, and shelf-life, limiting its practical applications in various settings.

Another critical challenge lies in maintaining the optimal pH range for HOCl effectiveness. The antimicrobial activity of HOCl is highest at a slightly acidic pH (around 5-6.5). However, maintaining this pH level consistently in different environments and applications can be problematic. pH fluctuations can significantly impact the efficacy of HOCl, potentially reducing its antimicrobial properties or altering its chemical composition.

The concentration of HOCl also presents a challenge in terms of balancing efficacy and safety. While higher concentrations may offer increased antimicrobial activity, they can also lead to potential irritation or toxicity, especially in sensitive applications such as wound care or food processing. Determining and maintaining the ideal concentration for specific use cases remains an ongoing challenge.

Furthermore, the interaction of HOCl with organic matter in real-world applications can diminish its effectiveness. In environments with high organic loads, such as in wound care or industrial settings, HOCl can be rapidly neutralized, reducing its antimicrobial efficacy. This necessitates either higher initial concentrations or more frequent applications, both of which come with their own set of challenges.

The potential for bacterial resistance development, although less pronounced compared to traditional antibiotics, remains a concern. While HOCl's mechanism of action makes it less likely for bacteria to develop resistance, the possibility cannot be entirely ruled out, especially with prolonged or improper use. Monitoring and managing potential resistance development is crucial for long-term efficacy.

Lastly, there are challenges related to the standardization and regulation of HOCl products. The variability in production methods, concentrations, and formulations across different manufacturers makes it difficult to establish uniform standards for efficacy and safety. This lack of standardization can lead to inconsistent performance and hinder broader acceptance in medical and industrial applications.

Another critical challenge lies in maintaining the optimal pH range for HOCl effectiveness. The antimicrobial activity of HOCl is highest at a slightly acidic pH (around 5-6.5). However, maintaining this pH level consistently in different environments and applications can be problematic. pH fluctuations can significantly impact the efficacy of HOCl, potentially reducing its antimicrobial properties or altering its chemical composition.

The concentration of HOCl also presents a challenge in terms of balancing efficacy and safety. While higher concentrations may offer increased antimicrobial activity, they can also lead to potential irritation or toxicity, especially in sensitive applications such as wound care or food processing. Determining and maintaining the ideal concentration for specific use cases remains an ongoing challenge.

Furthermore, the interaction of HOCl with organic matter in real-world applications can diminish its effectiveness. In environments with high organic loads, such as in wound care or industrial settings, HOCl can be rapidly neutralized, reducing its antimicrobial efficacy. This necessitates either higher initial concentrations or more frequent applications, both of which come with their own set of challenges.

The potential for bacterial resistance development, although less pronounced compared to traditional antibiotics, remains a concern. While HOCl's mechanism of action makes it less likely for bacteria to develop resistance, the possibility cannot be entirely ruled out, especially with prolonged or improper use. Monitoring and managing potential resistance development is crucial for long-term efficacy.

Lastly, there are challenges related to the standardization and regulation of HOCl products. The variability in production methods, concentrations, and formulations across different manufacturers makes it difficult to establish uniform standards for efficacy and safety. This lack of standardization can lead to inconsistent performance and hinder broader acceptance in medical and industrial applications.

Existing HOCl Formulations and Applications

01 Mechanisms of bacterial resistance to hypochlorous acid

Bacteria can develop resistance to hypochlorous acid through various mechanisms, including the production of protective enzymes, modification of cell membrane composition, and activation of efflux pumps. These adaptations help bacteria survive exposure to hypochlorous acid and maintain their viability in its presence.- Mechanisms of bacterial resistance to hypochlorous acid: Bacteria can develop resistance to hypochlorous acid through various mechanisms, including the production of protective enzymes, modification of cell membrane composition, and activation of efflux pumps. These adaptations help bacteria survive exposure to hypochlorous acid and maintain their viability in its presence.

- Combination therapies to overcome bacterial resistance: To combat bacterial resistance to hypochlorous acid, combination therapies involving other antimicrobial agents or adjuvants can be employed. These strategies aim to enhance the effectiveness of hypochlorous acid and prevent the development of resistance by targeting multiple bacterial pathways simultaneously.

- Optimizing hypochlorous acid formulations for enhanced efficacy: Improving the formulation of hypochlorous acid-based products can help overcome bacterial resistance. This may involve adjusting pH levels, incorporating stabilizers, or developing novel delivery systems to ensure optimal antimicrobial activity and minimize the potential for resistance development.

- Monitoring and managing bacterial resistance to hypochlorous acid: Implementing strategies to monitor and manage bacterial resistance to hypochlorous acid is crucial for maintaining its long-term effectiveness. This includes regular susceptibility testing, rotation of antimicrobial agents, and the development of resistance surveillance programs in healthcare and industrial settings.

- Novel applications of hypochlorous acid to mitigate bacterial resistance: Exploring new applications and delivery methods for hypochlorous acid can help address bacterial resistance issues. This may include the development of hypochlorous acid-based materials, coatings, or devices that provide sustained antimicrobial activity and reduce the likelihood of resistance development.

02 Combination therapies to overcome bacterial resistance

To combat bacterial resistance to hypochlorous acid, combination therapies involving other antimicrobial agents or adjuvants can be employed. These synergistic approaches may enhance the effectiveness of hypochlorous acid and reduce the likelihood of resistance development in bacteria.Expand Specific Solutions03 Novel formulations of hypochlorous acid for enhanced antimicrobial activity

Innovative formulations of hypochlorous acid, such as stabilized solutions or nanoparticle-based delivery systems, can improve its antimicrobial efficacy and potentially overcome bacterial resistance. These formulations may enhance penetration into bacterial cells or prolong the active lifetime of hypochlorous acid.Expand Specific Solutions04 Genetic factors influencing bacterial resistance to hypochlorous acid

Certain genetic factors in bacteria can contribute to their resistance against hypochlorous acid. Understanding these genetic elements and their regulation can provide insights into the mechanisms of resistance and potential targets for overcoming it.Expand Specific Solutions05 Environmental factors affecting hypochlorous acid efficacy and bacterial resistance

Various environmental factors, such as pH, temperature, and organic matter content, can influence the antimicrobial activity of hypochlorous acid and the development of bacterial resistance. Optimizing these conditions can help maintain the effectiveness of hypochlorous acid against resistant bacteria.Expand Specific Solutions

Key Players in HOCl Research and Production

The field of hypochlorous acid's influence on bacterial resistance is in a growth phase, with increasing market size and technological advancements. The global market for disinfectants, including hypochlorous acid-based products, is expanding due to heightened awareness of hygiene and infection control. Companies like Vertex Pharmaceuticals, Cedars-Sinai Medical Center, and Industrie De Nora SpA are at the forefront of research and development in this area. The technology is maturing, with firms such as ANNIHILARE MEDICAL SYSTEMS, INC. and Aquaox, Inc. offering innovative on-site generation systems for hypochlorous acid solutions. Academic institutions like Tongji University and Inner Mongolia Agricultural University are contributing to the scientific understanding of bacterial resistance mechanisms, further advancing the field's technological maturity.

WIAB WATER INNOVATION AB

Technical Solution: WIAB WATER INNOVATION AB has developed an innovative approach to generating hypochlorous acid (HOCl) for bacterial control. Their technology utilizes a patented electrolysis process to produce stable HOCl solutions on-site. This method ensures a consistent concentration of HOCl, typically around 500 ppm, which has been shown to be effective against a wide range of bacteria, including antibiotic-resistant strains[1]. The company's system incorporates real-time monitoring and adjustment of pH levels to maintain optimal HOCl efficacy, typically keeping the solution between pH 6.5-7.5[2]. This pH range ensures that the HOCl remains in its most active form, maximizing its antimicrobial properties while minimizing the development of bacterial resistance[3].

Strengths: On-site generation reduces transportation costs and environmental impact. Precise control over HOCl concentration and pH ensures consistent efficacy. Weaknesses: Requires specialized equipment and ongoing maintenance, which may limit adoption in resource-poor settings.

Vertex Pharmaceuticals, Inc.

Technical Solution: Vertex Pharmaceuticals has been exploring the potential of hypochlorous acid in combination with their existing antibiotic therapies to combat bacterial resistance. Their approach involves using HOCl as a pre-treatment or adjuvant therapy to enhance the efficacy of conventional antibiotics. In laboratory studies, they have demonstrated that low concentrations of HOCl (50-100 ppm) can disrupt bacterial biofilms, making antibiotic-resistant bacteria more susceptible to treatment[4]. The company is also investigating the use of HOCl in nebulized form for respiratory infections, particularly in cystic fibrosis patients where bacterial resistance is a significant concern. Preliminary data suggests that this combination therapy could reduce the required antibiotic dose by up to 40%, potentially slowing the development of resistance[5].

Strengths: Leverages existing antibiotic therapies, potentially extending their useful lifespan. Addresses the critical issue of biofilm-associated resistance. Weaknesses: Still in early stages of research, clinical efficacy and safety in combination therapies need to be established.

Innovations in HOCl Stability and Delivery

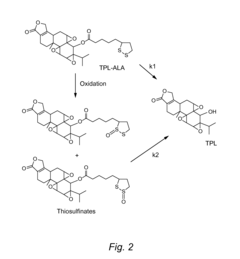

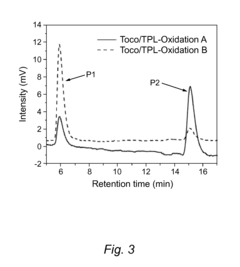

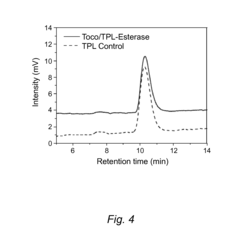

Antioxidant, Anti-inflammatory and anticancer derivatives of triptolide and nanospheres thereof

PatentInactiveUS20160115192A1

Innovation

- Development of triptolide nanoprodrugs that combine antioxidant, anti-inflammatory, and anticancer properties, specifically designed to target tumor tissues, inhibiting B7-H1 expression and delivering therapeutic agents like camptothecin, alpha-lipoic acid, or NSAIDs in a tumor-selective manner.

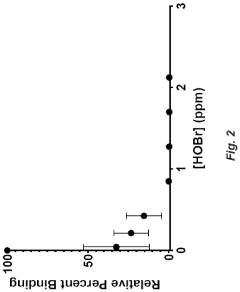

Hypohalous acids for treating inflammatory diseases and inhibiting growth of malignancies

PatentInactiveUS20220202853A1

Innovation

- Development of a novel electrochemical method to produce stable, pure hypohalous acids (HOCl and HOBr) that are free from hypochlorites and hypobromites, allowing for topical and inhalation-based delivery to inactivate IL-6 and other cytokines, thereby addressing the limitations of existing therapies and stability issues with hypohalous acids.

Regulatory Framework for HOCl-based Products

The regulatory framework for hypochlorous acid (HOCl)-based products is complex and varies across different regions and applications. In the United States, the Environmental Protection Agency (EPA) regulates HOCl as a pesticide under the Federal Insecticide, Fungicide, and Rodenticide Act (FIFRA). The EPA has approved HOCl for use as a disinfectant and sanitizer in various settings, including healthcare facilities, food processing plants, and water treatment systems.

The Food and Drug Administration (FDA) also plays a role in regulating HOCl-based products, particularly those intended for medical use or food contact surfaces. The FDA has classified HOCl as a Generally Recognized as Safe (GRAS) substance when used as an antimicrobial agent in food processing. However, specific formulations and applications may require additional FDA approval or clearance.

In the European Union, HOCl falls under the Biocidal Products Regulation (BPR), which governs the use of biocidal active substances and products. The European Chemicals Agency (ECHA) is responsible for implementing the BPR and evaluating the safety and efficacy of HOCl-based products. Manufacturers must obtain product authorization before placing HOCl-based biocidal products on the EU market.

The World Health Organization (WHO) has recognized HOCl as an effective disinfectant for various pathogens, including bacteria, viruses, and fungi. This recognition has influenced regulatory approaches in many countries, particularly in the context of water treatment and healthcare applications.

In Japan, HOCl is regulated by the Ministry of Health, Labour and Welfare (MHLW) under the Pharmaceutical Affairs Law. The MHLW has approved HOCl for use in medical devices and as a food additive, subject to specific concentration limits and application methods.

Regulatory bodies worldwide are increasingly focusing on the potential environmental impact of HOCl-based products. While HOCl is generally considered environmentally friendly due to its rapid breakdown into non-toxic components, regulators are examining the long-term effects of widespread use, particularly in aquatic ecosystems.

As research on bacterial resistance to HOCl continues to evolve, regulatory frameworks are adapting to incorporate new findings. Some jurisdictions are implementing guidelines for the appropriate use of HOCl-based products to minimize the risk of resistance development. These guidelines often include recommendations for proper concentration, contact time, and rotation with other disinfectants.

The regulatory landscape for HOCl-based products is dynamic, with ongoing efforts to harmonize standards across different regions and applications. International organizations such as the International Organization for Standardization (ISO) are working to develop global standards for the production, testing, and application of HOCl, which may influence future regulatory approaches.

The Food and Drug Administration (FDA) also plays a role in regulating HOCl-based products, particularly those intended for medical use or food contact surfaces. The FDA has classified HOCl as a Generally Recognized as Safe (GRAS) substance when used as an antimicrobial agent in food processing. However, specific formulations and applications may require additional FDA approval or clearance.

In the European Union, HOCl falls under the Biocidal Products Regulation (BPR), which governs the use of biocidal active substances and products. The European Chemicals Agency (ECHA) is responsible for implementing the BPR and evaluating the safety and efficacy of HOCl-based products. Manufacturers must obtain product authorization before placing HOCl-based biocidal products on the EU market.

The World Health Organization (WHO) has recognized HOCl as an effective disinfectant for various pathogens, including bacteria, viruses, and fungi. This recognition has influenced regulatory approaches in many countries, particularly in the context of water treatment and healthcare applications.

In Japan, HOCl is regulated by the Ministry of Health, Labour and Welfare (MHLW) under the Pharmaceutical Affairs Law. The MHLW has approved HOCl for use in medical devices and as a food additive, subject to specific concentration limits and application methods.

Regulatory bodies worldwide are increasingly focusing on the potential environmental impact of HOCl-based products. While HOCl is generally considered environmentally friendly due to its rapid breakdown into non-toxic components, regulators are examining the long-term effects of widespread use, particularly in aquatic ecosystems.

As research on bacterial resistance to HOCl continues to evolve, regulatory frameworks are adapting to incorporate new findings. Some jurisdictions are implementing guidelines for the appropriate use of HOCl-based products to minimize the risk of resistance development. These guidelines often include recommendations for proper concentration, contact time, and rotation with other disinfectants.

The regulatory landscape for HOCl-based products is dynamic, with ongoing efforts to harmonize standards across different regions and applications. International organizations such as the International Organization for Standardization (ISO) are working to develop global standards for the production, testing, and application of HOCl, which may influence future regulatory approaches.

Environmental Impact of HOCl Usage

The use of hypochlorous acid (HOCl) as a disinfectant has gained significant attention due to its effectiveness against a wide range of microorganisms. However, its widespread application raises concerns about potential environmental impacts. HOCl is a highly reactive oxidizing agent that can interact with various organic and inorganic compounds in the environment, potentially leading to unintended consequences.

One of the primary environmental concerns associated with HOCl usage is its potential to form disinfection by-products (DBPs) when it reacts with organic matter in water. These DBPs, such as trihalomethanes and haloacetic acids, can have adverse effects on aquatic ecosystems and human health. The formation of DBPs depends on factors like HOCl concentration, contact time, and the presence of organic precursors in the water.

Another environmental consideration is the impact of HOCl on non-target organisms. While HOCl is effective against harmful bacteria, it may also affect beneficial microorganisms in soil and water ecosystems. This disruption of microbial communities could potentially alter nutrient cycling and ecosystem functions. Additionally, the release of HOCl into aquatic environments may harm sensitive aquatic species, particularly in cases of accidental spills or improper disposal.

The persistence of HOCl in the environment is relatively short-lived due to its high reactivity. It rapidly decomposes into chloride ions and water, which are generally considered harmless. This characteristic reduces the long-term environmental impact of HOCl compared to more persistent disinfectants. However, the continuous application of HOCl in certain settings may lead to localized accumulation of chloride ions, potentially affecting soil and water chemistry.

The production and transportation of HOCl also contribute to its environmental footprint. The energy requirements and chemical processes involved in manufacturing HOCl can result in greenhouse gas emissions and resource consumption. Furthermore, the packaging and distribution of HOCl products may generate plastic waste and contribute to transportation-related emissions.

To mitigate the environmental impact of HOCl usage, several strategies can be employed. These include optimizing dosage and application methods to minimize excess use, implementing proper disposal protocols to prevent environmental contamination, and exploring on-site generation technologies to reduce transportation and packaging-related impacts. Additionally, ongoing research into the development of more environmentally friendly disinfection alternatives and improved HOCl formulations may help address some of the current environmental concerns associated with its use.

One of the primary environmental concerns associated with HOCl usage is its potential to form disinfection by-products (DBPs) when it reacts with organic matter in water. These DBPs, such as trihalomethanes and haloacetic acids, can have adverse effects on aquatic ecosystems and human health. The formation of DBPs depends on factors like HOCl concentration, contact time, and the presence of organic precursors in the water.

Another environmental consideration is the impact of HOCl on non-target organisms. While HOCl is effective against harmful bacteria, it may also affect beneficial microorganisms in soil and water ecosystems. This disruption of microbial communities could potentially alter nutrient cycling and ecosystem functions. Additionally, the release of HOCl into aquatic environments may harm sensitive aquatic species, particularly in cases of accidental spills or improper disposal.

The persistence of HOCl in the environment is relatively short-lived due to its high reactivity. It rapidly decomposes into chloride ions and water, which are generally considered harmless. This characteristic reduces the long-term environmental impact of HOCl compared to more persistent disinfectants. However, the continuous application of HOCl in certain settings may lead to localized accumulation of chloride ions, potentially affecting soil and water chemistry.

The production and transportation of HOCl also contribute to its environmental footprint. The energy requirements and chemical processes involved in manufacturing HOCl can result in greenhouse gas emissions and resource consumption. Furthermore, the packaging and distribution of HOCl products may generate plastic waste and contribute to transportation-related emissions.

To mitigate the environmental impact of HOCl usage, several strategies can be employed. These include optimizing dosage and application methods to minimize excess use, implementing proper disposal protocols to prevent environmental contamination, and exploring on-site generation technologies to reduce transportation and packaging-related impacts. Additionally, ongoing research into the development of more environmentally friendly disinfection alternatives and improved HOCl formulations may help address some of the current environmental concerns associated with its use.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!