The Emerging Field of Hypochlorous Acid in Space Hygiene Solutions

AUG 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

HOCL Space Hygiene Background and Objectives

Hypochlorous acid (HOCl) has emerged as a promising solution for space hygiene, addressing the unique challenges of maintaining cleanliness and preventing microbial growth in extraterrestrial environments. The development of HOCl-based technologies for space applications represents a significant advancement in the field of space exploration and long-term habitation.

The primary objective of incorporating HOCl in space hygiene solutions is to provide a safe, effective, and versatile antimicrobial agent that can function efficiently in the constraints of space missions. This technology aims to enhance the overall health and safety of astronauts by minimizing the risk of infections and contamination in enclosed spacecraft environments.

HOCl's potential in space hygiene stems from its natural occurrence in the human immune system, where it serves as a powerful oxidant produced by neutrophils to combat pathogens. This biological compatibility makes HOCl an attractive option for use in human-occupied spacecraft, as it poses minimal risk of adverse effects on crew members while effectively eliminating a broad spectrum of microorganisms.

The evolution of HOCl technology for space applications builds upon decades of research in terrestrial settings, where it has been utilized in various industries, including healthcare, food processing, and water treatment. The adaptation of this technology for space use involves overcoming specific challenges related to microgravity, radiation exposure, and the closed-loop systems characteristic of spacecraft environments.

One of the key goals in developing HOCl-based space hygiene solutions is to create a sustainable and regenerative system that can produce the compound on-demand using minimal resources. This approach aligns with the broader objectives of space exploration, which emphasize resource efficiency and closed-loop life support systems for extended missions and potential planetary colonization.

The integration of HOCl technology into space hygiene protocols also aims to address the limitations of traditional cleaning and disinfection methods in space. Conventional chemical disinfectants often pose storage, handling, and disposal challenges in the confined spaces of spacecraft. HOCl offers a more environmentally friendly alternative that can be generated on-site, reducing the need for transporting large quantities of cleaning supplies from Earth.

Furthermore, the development of HOCl-based space hygiene solutions seeks to enhance the versatility of cleaning and disinfection processes in space. The technology is being explored for various applications, including surface disinfection, water purification, air sanitization, and even potential medical uses for wound care and infection prevention among crew members.

The primary objective of incorporating HOCl in space hygiene solutions is to provide a safe, effective, and versatile antimicrobial agent that can function efficiently in the constraints of space missions. This technology aims to enhance the overall health and safety of astronauts by minimizing the risk of infections and contamination in enclosed spacecraft environments.

HOCl's potential in space hygiene stems from its natural occurrence in the human immune system, where it serves as a powerful oxidant produced by neutrophils to combat pathogens. This biological compatibility makes HOCl an attractive option for use in human-occupied spacecraft, as it poses minimal risk of adverse effects on crew members while effectively eliminating a broad spectrum of microorganisms.

The evolution of HOCl technology for space applications builds upon decades of research in terrestrial settings, where it has been utilized in various industries, including healthcare, food processing, and water treatment. The adaptation of this technology for space use involves overcoming specific challenges related to microgravity, radiation exposure, and the closed-loop systems characteristic of spacecraft environments.

One of the key goals in developing HOCl-based space hygiene solutions is to create a sustainable and regenerative system that can produce the compound on-demand using minimal resources. This approach aligns with the broader objectives of space exploration, which emphasize resource efficiency and closed-loop life support systems for extended missions and potential planetary colonization.

The integration of HOCl technology into space hygiene protocols also aims to address the limitations of traditional cleaning and disinfection methods in space. Conventional chemical disinfectants often pose storage, handling, and disposal challenges in the confined spaces of spacecraft. HOCl offers a more environmentally friendly alternative that can be generated on-site, reducing the need for transporting large quantities of cleaning supplies from Earth.

Furthermore, the development of HOCl-based space hygiene solutions seeks to enhance the versatility of cleaning and disinfection processes in space. The technology is being explored for various applications, including surface disinfection, water purification, air sanitization, and even potential medical uses for wound care and infection prevention among crew members.

Space Hygiene Market Analysis

The space hygiene market is experiencing significant growth and transformation, driven by the increasing frequency and duration of space missions, as well as the growing emphasis on astronaut health and safety. As space exploration ventures expand, including plans for long-term lunar habitation and potential Mars missions, the demand for effective hygiene solutions in space environments is escalating.

The market for space hygiene products and technologies is currently dominated by traditional chemical-based disinfectants and specialized cleaning tools designed for microgravity environments. However, there is a notable shift towards more sustainable, efficient, and versatile solutions, with hypochlorous acid (HOCl) emerging as a promising contender in this field.

Key factors influencing the space hygiene market include the need for lightweight, multi-functional products that conserve valuable spacecraft resources, such as water and storage space. Additionally, there is a growing focus on developing solutions that can effectively combat a wide range of microorganisms while being safe for both astronauts and sensitive equipment.

The market is segmented into various categories, including personal hygiene products, surface disinfectants, air purification systems, and waste management solutions. Among these, surface disinfectants and air purification systems are experiencing the most rapid growth, driven by the critical need to maintain a sterile environment in enclosed spacecraft.

Geographically, the space hygiene market is primarily led by countries with advanced space programs, such as the United States, Russia, China, and member states of the European Space Agency. However, emerging space powers like India and private space companies are also contributing to market expansion and innovation.

The introduction of hypochlorous acid-based solutions is poised to disrupt the existing market landscape. HOCl offers several advantages over traditional disinfectants, including broad-spectrum antimicrobial efficacy, non-toxicity, and compatibility with various materials used in spacecraft construction. These properties make it an attractive option for addressing the unique challenges of maintaining hygiene in space environments.

As research and development in this area progress, the space hygiene market is expected to witness the entry of new players specializing in HOCl-based technologies. This influx of innovation is likely to drive competition and further technological advancements, ultimately benefiting space agencies and commercial space ventures alike.

The market for space hygiene products and technologies is currently dominated by traditional chemical-based disinfectants and specialized cleaning tools designed for microgravity environments. However, there is a notable shift towards more sustainable, efficient, and versatile solutions, with hypochlorous acid (HOCl) emerging as a promising contender in this field.

Key factors influencing the space hygiene market include the need for lightweight, multi-functional products that conserve valuable spacecraft resources, such as water and storage space. Additionally, there is a growing focus on developing solutions that can effectively combat a wide range of microorganisms while being safe for both astronauts and sensitive equipment.

The market is segmented into various categories, including personal hygiene products, surface disinfectants, air purification systems, and waste management solutions. Among these, surface disinfectants and air purification systems are experiencing the most rapid growth, driven by the critical need to maintain a sterile environment in enclosed spacecraft.

Geographically, the space hygiene market is primarily led by countries with advanced space programs, such as the United States, Russia, China, and member states of the European Space Agency. However, emerging space powers like India and private space companies are also contributing to market expansion and innovation.

The introduction of hypochlorous acid-based solutions is poised to disrupt the existing market landscape. HOCl offers several advantages over traditional disinfectants, including broad-spectrum antimicrobial efficacy, non-toxicity, and compatibility with various materials used in spacecraft construction. These properties make it an attractive option for addressing the unique challenges of maintaining hygiene in space environments.

As research and development in this area progress, the space hygiene market is expected to witness the entry of new players specializing in HOCl-based technologies. This influx of innovation is likely to drive competition and further technological advancements, ultimately benefiting space agencies and commercial space ventures alike.

HOCL Technology Status and Challenges

The current status of hypochlorous acid (HOCl) technology in space hygiene solutions is characterized by promising advancements and significant challenges. HOCl has gained attention in the space industry due to its potent antimicrobial properties and potential as a safe, eco-friendly disinfectant. However, its application in space environments presents unique obstacles that researchers and engineers are actively addressing.

One of the primary challenges is the stability of HOCl in space conditions. The microgravity environment and radiation exposure can potentially affect the chemical composition and efficacy of HOCl solutions. Researchers are exploring various stabilization techniques, including the development of advanced storage systems and the incorporation of stabilizing agents to maintain the potency of HOCl over extended periods in space.

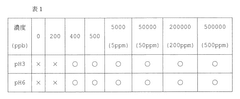

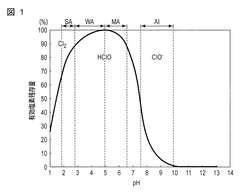

Another significant hurdle is the production and storage of HOCl in space. Current methods of HOCl generation often require specialized equipment and precise control of pH levels, which can be challenging in the confined and resource-limited environment of spacecraft. Efforts are underway to develop compact, energy-efficient systems for on-demand HOCl production that can operate reliably in space conditions.

The integration of HOCl-based hygiene solutions into existing spacecraft systems poses additional challenges. Engineers must consider factors such as compatibility with spacecraft materials, potential off-gassing effects, and the impact on life support systems. Extensive testing and validation processes are necessary to ensure that HOCl-based products do not interfere with critical spacecraft operations or pose any risks to crew health.

From a global perspective, the development of HOCl technology for space applications is primarily concentrated in countries with advanced space programs. The United States, through NASA and private space companies, is at the forefront of this research. European Space Agency (ESA) member states and Japan are also actively contributing to the field. Collaboration between space agencies and research institutions worldwide is facilitating knowledge exchange and accelerating progress in overcoming technical challenges.

Despite these challenges, recent advancements in HOCl technology have shown promising results. Researchers have made progress in developing more stable HOCl formulations and exploring novel delivery methods suitable for space environments. Additionally, ongoing studies are investigating the long-term effects of HOCl use in closed systems, which is crucial for extended space missions.

As the field evolves, addressing these technical hurdles will be critical in realizing the full potential of HOCl as a space hygiene solution. The successful implementation of HOCl technology in space could significantly enhance sanitation protocols, reduce the risk of microbial contamination, and contribute to the overall health and safety of astronauts during long-duration space missions.

One of the primary challenges is the stability of HOCl in space conditions. The microgravity environment and radiation exposure can potentially affect the chemical composition and efficacy of HOCl solutions. Researchers are exploring various stabilization techniques, including the development of advanced storage systems and the incorporation of stabilizing agents to maintain the potency of HOCl over extended periods in space.

Another significant hurdle is the production and storage of HOCl in space. Current methods of HOCl generation often require specialized equipment and precise control of pH levels, which can be challenging in the confined and resource-limited environment of spacecraft. Efforts are underway to develop compact, energy-efficient systems for on-demand HOCl production that can operate reliably in space conditions.

The integration of HOCl-based hygiene solutions into existing spacecraft systems poses additional challenges. Engineers must consider factors such as compatibility with spacecraft materials, potential off-gassing effects, and the impact on life support systems. Extensive testing and validation processes are necessary to ensure that HOCl-based products do not interfere with critical spacecraft operations or pose any risks to crew health.

From a global perspective, the development of HOCl technology for space applications is primarily concentrated in countries with advanced space programs. The United States, through NASA and private space companies, is at the forefront of this research. European Space Agency (ESA) member states and Japan are also actively contributing to the field. Collaboration between space agencies and research institutions worldwide is facilitating knowledge exchange and accelerating progress in overcoming technical challenges.

Despite these challenges, recent advancements in HOCl technology have shown promising results. Researchers have made progress in developing more stable HOCl formulations and exploring novel delivery methods suitable for space environments. Additionally, ongoing studies are investigating the long-term effects of HOCl use in closed systems, which is crucial for extended space missions.

As the field evolves, addressing these technical hurdles will be critical in realizing the full potential of HOCl as a space hygiene solution. The successful implementation of HOCl technology in space could significantly enhance sanitation protocols, reduce the risk of microbial contamination, and contribute to the overall health and safety of astronauts during long-duration space missions.

Current HOCL Space Solutions

01 Production methods of hypochlorous acid

Various methods are employed to produce hypochlorous acid, including electrolysis of salt solutions, chemical reactions involving chlorine and water, and controlled mixing of precursor chemicals. These production methods aim to create stable and effective hypochlorous acid solutions for different applications.- Production methods of hypochlorous acid: Various methods are employed to produce hypochlorous acid, including electrolysis of salt solutions, chemical reactions involving chlorine and water, and controlled mixing of precursor chemicals. These production methods aim to create stable and effective hypochlorous acid solutions for different applications.

- Antimicrobial applications of hypochlorous acid: Hypochlorous acid is widely used as an antimicrobial agent in various fields, including healthcare, food processing, and water treatment. Its effectiveness against a broad spectrum of pathogens, combined with its low toxicity to humans, makes it a valuable disinfectant and sanitizer.

- Stabilization techniques for hypochlorous acid solutions: Stabilization of hypochlorous acid solutions is crucial for maintaining their efficacy over time. Various techniques are employed, such as pH adjustment, addition of stabilizing agents, and specialized packaging methods, to extend the shelf life and preserve the antimicrobial properties of hypochlorous acid products.

- Medical and therapeutic uses of hypochlorous acid: Hypochlorous acid finds applications in medical and therapeutic contexts, including wound care, eye care, and respiratory treatments. Its ability to effectively kill pathogens while being gentle on human tissues makes it suitable for various medical applications and treatments.

- Environmental and industrial applications of hypochlorous acid: Hypochlorous acid is utilized in environmental and industrial settings for purposes such as water treatment, air purification, and surface disinfection. Its eco-friendly nature and broad-spectrum antimicrobial activity make it suitable for various large-scale applications in different industries.

02 Antimicrobial applications of hypochlorous acid

Hypochlorous acid is widely used as an antimicrobial agent in various fields, including healthcare, food processing, and water treatment. Its effectiveness against a broad spectrum of pathogens, combined with its low toxicity to humans, makes it a valuable disinfectant and sanitizer.Expand Specific Solutions03 Stabilization and formulation of hypochlorous acid solutions

Techniques for stabilizing hypochlorous acid solutions are crucial for maintaining their efficacy over time. This includes pH adjustment, addition of stabilizing agents, and specialized packaging to prevent degradation. Formulation strategies aim to enhance shelf life and preserve the active properties of hypochlorous acid.Expand Specific Solutions04 Medical and therapeutic uses of hypochlorous acid

Hypochlorous acid finds applications in various medical and therapeutic contexts, including wound care, eye care, and respiratory treatments. Its natural occurrence in the human immune system and low cytotoxicity make it suitable for these sensitive applications.Expand Specific Solutions05 Environmental and industrial applications of hypochlorous acid

Hypochlorous acid is utilized in environmental remediation, water treatment, and various industrial processes. Its strong oxidizing properties make it effective for decontamination, odor control, and as a cleaning agent in industrial settings, while its biodegradability offers environmental benefits.Expand Specific Solutions

Key Players in Space Hygiene

The emerging field of hypochlorous acid in space hygiene solutions is in its early stages of development, with a growing market potential due to increased focus on sanitation in space environments. The technology is still evolving, with varying levels of maturity among key players. Companies like Panasonic, Toshiba, and Nipro Corp. are leveraging their expertise in electronics and medical equipment to advance hypochlorous acid applications. Smaller specialized firms such as WIAB Water Innovation AB and Aquaox, Inc. are focusing on innovative water treatment solutions. Research institutions like Toho University and Fudan University are contributing to the scientific understanding of hypochlorous acid's properties and potential uses in space hygiene. The competitive landscape is diverse, with both established corporations and emerging startups vying for market share in this promising sector.

Panasonic Intellectual Property Management Co. Ltd.

Technical Solution: Panasonic has developed an electrolyzed water generation system that produces hypochlorous acid for disinfection purposes. Their technology focuses on creating a stable HOCl solution with a long shelf life, which is crucial for space applications where resupply missions are infrequent. The system utilizes a membrane electrolysis method to generate HOCl with a concentration of 10-30 ppm and a pH level between 5.0-6.5[3]. Panasonic's approach includes a unique electrode coating technology that enhances the efficiency and longevity of the electrolysis process, potentially reducing maintenance requirements in space environments[4].

Strengths: Long shelf life of HOCl solution; efficient electrode technology. Weaknesses: Lower concentration of HOCl compared to some competitors; may require adaptation for space-specific challenges.

WIAB WATER INNOVATION AB

Technical Solution: WIAB has pioneered a novel approach to HOCl production using a patented electrolysis cell design. Their technology focuses on creating highly stable HOCl solutions with minimal by-products, which is crucial for maintaining air and water quality in closed space environments. WIAB's system produces HOCl with a concentration of 200-500 ppm and a pH range of 6.0-7.0, striking a balance between efficacy and material compatibility[8]. The company has also developed a unique membrane technology that allows for the separation of HOCl from other electrolysis products, potentially reducing the need for additional purification steps in space applications[9].

Strengths: High stability of HOCl solution; minimal by-product production. Weaknesses: May require adaptation for microgravity operation; potential energy intensity for high-concentration production.

HOCL Space Application Patents

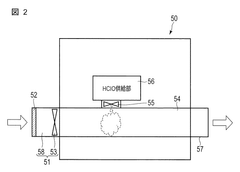

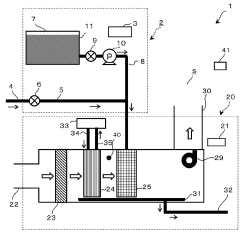

Space sterilization device and space deodorization device

PatentWO2016189757A1

Innovation

- A space sterilization device that supplies gaseous or mist hypochlorous acid water at concentrations between 400 ppb and 500 ppm, using a hypochlorous acid water supply unit with a measurement system to maintain optimal levels, preventing adverse effects and ensuring sufficient sterilization and deodorization without corrosion.

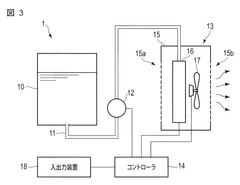

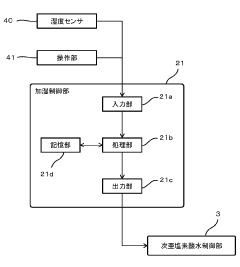

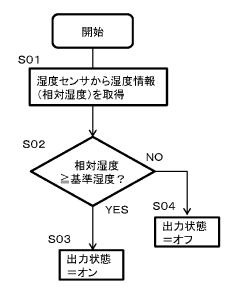

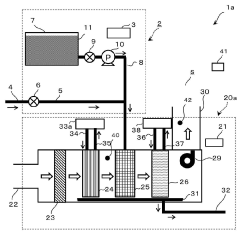

Space purification system

PatentInactiveJP2023110146A

Innovation

- A space purification system with a temperature control unit, humidity sensor, hypochlorous acid water supply device, and humidification control unit that regulates the addition of hypochlorous acid water based on relative humidity levels, ensuring it is applied only when the humidity is at or above a reference level, typically 90%, thereby preventing excessive humidification.

Microgravity Effects on HOCL

The effects of microgravity on hypochlorous acid (HOCl) in space hygiene solutions present unique challenges and opportunities for maintaining cleanliness and disinfection in extraterrestrial environments. In the absence of gravity, fluid dynamics and chemical reactions behave differently, potentially altering the efficacy and application methods of HOCl-based disinfectants.

Microgravity conditions can significantly impact the distribution and surface tension of liquids, including HOCl solutions. Without the influence of gravity, these solutions tend to form spherical droplets due to surface tension, which can affect their ability to spread and coat surfaces effectively. This phenomenon may require the development of specialized application techniques or modified formulations to ensure adequate coverage and contact time with surfaces requiring disinfection.

The lack of natural convection in microgravity environments can also influence the mixing and dispersion of HOCl solutions. In terrestrial settings, density differences caused by gravity drive convection currents, which help distribute disinfectants evenly. In space, alternative methods such as forced convection or mechanical agitation may be necessary to ensure uniform distribution of HOCl throughout the target area.

Microgravity can affect the stability and shelf-life of HOCl solutions. The absence of sedimentation and reduced molecular movement may impact the chemical equilibrium and degradation rates of HOCl. This could potentially lead to longer-lasting solutions, but it may also require careful monitoring and storage practices to maintain optimal disinfection efficacy over extended periods in space environments.

The altered behavior of airborne particles and droplets in microgravity presents both challenges and opportunities for HOCl-based disinfection systems. While the lack of gravitational settling may increase the persistence of aerosolized HOCl in the air, it could also lead to more uniform distribution throughout enclosed spaces. This characteristic could be leveraged to develop novel air purification systems using HOCl mists or vapors for continuous disinfection of spacecraft atmospheres.

The interaction between HOCl and various materials used in spacecraft construction and equipment must be carefully evaluated under microgravity conditions. The prolonged contact time and altered surface interactions may affect corrosion rates, material degradation, or the formation of byproducts. Extensive testing and material compatibility studies will be crucial to ensure the safe and effective use of HOCl-based disinfectants in space environments.

Microgravity may also influence the biological efficacy of HOCl against microorganisms. Some studies have shown that certain bacteria exhibit increased virulence and resistance to antimicrobial agents in space. Research is needed to determine whether the oxidative properties of HOCl remain equally effective against microbial contaminants under microgravity conditions and to optimize concentrations and exposure times accordingly.

Microgravity conditions can significantly impact the distribution and surface tension of liquids, including HOCl solutions. Without the influence of gravity, these solutions tend to form spherical droplets due to surface tension, which can affect their ability to spread and coat surfaces effectively. This phenomenon may require the development of specialized application techniques or modified formulations to ensure adequate coverage and contact time with surfaces requiring disinfection.

The lack of natural convection in microgravity environments can also influence the mixing and dispersion of HOCl solutions. In terrestrial settings, density differences caused by gravity drive convection currents, which help distribute disinfectants evenly. In space, alternative methods such as forced convection or mechanical agitation may be necessary to ensure uniform distribution of HOCl throughout the target area.

Microgravity can affect the stability and shelf-life of HOCl solutions. The absence of sedimentation and reduced molecular movement may impact the chemical equilibrium and degradation rates of HOCl. This could potentially lead to longer-lasting solutions, but it may also require careful monitoring and storage practices to maintain optimal disinfection efficacy over extended periods in space environments.

The altered behavior of airborne particles and droplets in microgravity presents both challenges and opportunities for HOCl-based disinfection systems. While the lack of gravitational settling may increase the persistence of aerosolized HOCl in the air, it could also lead to more uniform distribution throughout enclosed spaces. This characteristic could be leveraged to develop novel air purification systems using HOCl mists or vapors for continuous disinfection of spacecraft atmospheres.

The interaction between HOCl and various materials used in spacecraft construction and equipment must be carefully evaluated under microgravity conditions. The prolonged contact time and altered surface interactions may affect corrosion rates, material degradation, or the formation of byproducts. Extensive testing and material compatibility studies will be crucial to ensure the safe and effective use of HOCl-based disinfectants in space environments.

Microgravity may also influence the biological efficacy of HOCl against microorganisms. Some studies have shown that certain bacteria exhibit increased virulence and resistance to antimicrobial agents in space. Research is needed to determine whether the oxidative properties of HOCl remain equally effective against microbial contaminants under microgravity conditions and to optimize concentrations and exposure times accordingly.

Space Regulatory Framework

The regulatory framework for space activities plays a crucial role in ensuring the safe and responsible use of hypochlorous acid in space hygiene solutions. As space exploration and habitation become more prevalent, international space agencies and governing bodies have recognized the need for comprehensive guidelines to address the unique challenges of maintaining cleanliness and preventing contamination in extraterrestrial environments.

The United Nations Office for Outer Space Affairs (UNOOSA) has established the Committee on the Peaceful Uses of Outer Space (COPUOS) to develop and oversee international space law. This committee has been instrumental in creating treaties and principles that govern space activities, including those related to hygiene and contamination prevention. The Outer Space Treaty of 1967 serves as the foundation for international space law and emphasizes the importance of avoiding harmful contamination of celestial bodies.

NASA and other space agencies have developed specific protocols for planetary protection, which aim to prevent the contamination of extraterrestrial environments with Earth-based microorganisms. These protocols are particularly relevant to the use of hypochlorous acid in space hygiene solutions, as they dictate the acceptable levels of microbial contamination on spacecraft and equipment.

The International Space Station (ISS) has its own set of regulations and procedures for maintaining a clean and safe environment. These guidelines cover the use of cleaning agents, including hypochlorous acid-based solutions, and outline proper handling, storage, and disposal methods. The ISS Environmental Control and Life Support System (ECLSS) requirements provide a framework for evaluating and implementing new hygiene technologies.

As commercial space activities expand, regulatory bodies are adapting to address the needs of private entities. The Federal Aviation Administration (FAA) in the United States has established regulations for commercial space transportation, which include provisions for ensuring the safety and cleanliness of spacecraft. These regulations may influence the adoption and use of hypochlorous acid-based hygiene solutions in commercial space ventures.

International collaboration is essential in developing and harmonizing space hygiene regulations. The Inter-Agency Space Debris Coordination Committee (IADC) and the International Organization for Standardization (ISO) have been working on creating standards for space operations, including those related to cleanliness and contamination control. These efforts contribute to a more unified approach to space hygiene practices across different nations and organizations.

The United Nations Office for Outer Space Affairs (UNOOSA) has established the Committee on the Peaceful Uses of Outer Space (COPUOS) to develop and oversee international space law. This committee has been instrumental in creating treaties and principles that govern space activities, including those related to hygiene and contamination prevention. The Outer Space Treaty of 1967 serves as the foundation for international space law and emphasizes the importance of avoiding harmful contamination of celestial bodies.

NASA and other space agencies have developed specific protocols for planetary protection, which aim to prevent the contamination of extraterrestrial environments with Earth-based microorganisms. These protocols are particularly relevant to the use of hypochlorous acid in space hygiene solutions, as they dictate the acceptable levels of microbial contamination on spacecraft and equipment.

The International Space Station (ISS) has its own set of regulations and procedures for maintaining a clean and safe environment. These guidelines cover the use of cleaning agents, including hypochlorous acid-based solutions, and outline proper handling, storage, and disposal methods. The ISS Environmental Control and Life Support System (ECLSS) requirements provide a framework for evaluating and implementing new hygiene technologies.

As commercial space activities expand, regulatory bodies are adapting to address the needs of private entities. The Federal Aviation Administration (FAA) in the United States has established regulations for commercial space transportation, which include provisions for ensuring the safety and cleanliness of spacecraft. These regulations may influence the adoption and use of hypochlorous acid-based hygiene solutions in commercial space ventures.

International collaboration is essential in developing and harmonizing space hygiene regulations. The Inter-Agency Space Debris Coordination Committee (IADC) and the International Organization for Standardization (ISO) have been working on creating standards for space operations, including those related to cleanliness and contamination control. These efforts contribute to a more unified approach to space hygiene practices across different nations and organizations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!