Sodium Alginate Integration in 3D Bioprinting Solutions

JUL 14, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

3D Bioprinting Evolution

3D bioprinting has undergone a remarkable evolution since its inception in the early 2000s. Initially, the technology was limited to simple structures using hydrogels and cell suspensions. The integration of sodium alginate marked a significant milestone in this journey, enhancing the printability and stability of bioinks.

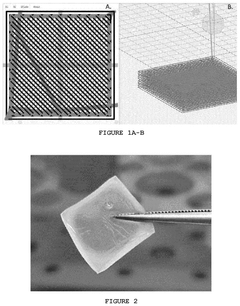

The first generation of 3D bioprinters focused on extrusion-based techniques, utilizing alginate's rapid crosslinking properties to create basic tissue constructs. These early models laid the groundwork for more complex applications but were constrained by low resolution and limited material options.

As the field progressed, the second generation of bioprinters emerged, incorporating multiple print heads and improved precision. This advancement allowed for the creation of more intricate structures, combining sodium alginate with other biomaterials to mimic tissue complexity. The integration of temperature control systems further expanded the range of printable materials, including those with temperature-sensitive gelation properties.

The third generation brought about a paradigm shift with the introduction of light-based bioprinting techniques. Stereolithography and digital light processing methods were adapted for bioprinting, allowing for higher resolution and faster printing speeds. Sodium alginate's role evolved to include photocrosslinkable derivatives, expanding its utility in these advanced systems.

Concurrently, the development of support bath techniques, such as freeform reversible embedding of suspended hydrogels (FRESH), revolutionized the printing of soft materials. This innovation enabled the creation of complex, hollow structures that were previously challenging to produce, with sodium alginate playing a crucial role in maintaining structural integrity during the printing process.

Recent advancements have focused on multi-material bioprinting, where sodium alginate serves as a versatile component in bioink formulations. Its ability to form interpenetrating networks with other polymers has led to the development of bioinks with tunable mechanical and biological properties, closely mimicking native tissue environments.

The latest frontier in 3D bioprinting involves the integration of microfluidic devices directly into the printing process. This approach allows for the precise deposition of cell-laden alginate droplets, enabling the creation of highly organized tissue structures with controlled cell distribution and vascularization.

As we look to the future, the evolution of 3D bioprinting continues to push boundaries. Emerging technologies such as 4D bioprinting, where printed constructs can change shape or function over time, are beginning to incorporate stimuli-responsive alginate derivatives. These advancements promise to revolutionize tissue engineering and regenerative medicine, bringing us closer to the goal of creating fully functional, transplantable organs.

The first generation of 3D bioprinters focused on extrusion-based techniques, utilizing alginate's rapid crosslinking properties to create basic tissue constructs. These early models laid the groundwork for more complex applications but were constrained by low resolution and limited material options.

As the field progressed, the second generation of bioprinters emerged, incorporating multiple print heads and improved precision. This advancement allowed for the creation of more intricate structures, combining sodium alginate with other biomaterials to mimic tissue complexity. The integration of temperature control systems further expanded the range of printable materials, including those with temperature-sensitive gelation properties.

The third generation brought about a paradigm shift with the introduction of light-based bioprinting techniques. Stereolithography and digital light processing methods were adapted for bioprinting, allowing for higher resolution and faster printing speeds. Sodium alginate's role evolved to include photocrosslinkable derivatives, expanding its utility in these advanced systems.

Concurrently, the development of support bath techniques, such as freeform reversible embedding of suspended hydrogels (FRESH), revolutionized the printing of soft materials. This innovation enabled the creation of complex, hollow structures that were previously challenging to produce, with sodium alginate playing a crucial role in maintaining structural integrity during the printing process.

Recent advancements have focused on multi-material bioprinting, where sodium alginate serves as a versatile component in bioink formulations. Its ability to form interpenetrating networks with other polymers has led to the development of bioinks with tunable mechanical and biological properties, closely mimicking native tissue environments.

The latest frontier in 3D bioprinting involves the integration of microfluidic devices directly into the printing process. This approach allows for the precise deposition of cell-laden alginate droplets, enabling the creation of highly organized tissue structures with controlled cell distribution and vascularization.

As we look to the future, the evolution of 3D bioprinting continues to push boundaries. Emerging technologies such as 4D bioprinting, where printed constructs can change shape or function over time, are beginning to incorporate stimuli-responsive alginate derivatives. These advancements promise to revolutionize tissue engineering and regenerative medicine, bringing us closer to the goal of creating fully functional, transplantable organs.

Market Demand Analysis

The market demand for sodium alginate in 3D bioprinting solutions has been experiencing significant growth in recent years, driven by advancements in tissue engineering, regenerative medicine, and personalized healthcare. This natural, biocompatible polymer derived from brown seaweed has gained traction due to its unique properties that make it ideal for bioink formulations.

In the pharmaceutical and biotechnology sectors, there is a growing need for more accurate and efficient drug testing platforms. 3D bioprinted tissues and organs using sodium alginate-based bioinks offer a promising alternative to traditional 2D cell cultures and animal models. This shift towards more physiologically relevant testing environments is expected to drive market demand for sodium alginate in bioprinting applications.

The healthcare industry, particularly in the field of regenerative medicine, shows substantial interest in sodium alginate-based 3D bioprinting solutions. The ability to create patient-specific tissue constructs and implants has the potential to revolutionize treatments for various conditions, including cartilage defects, bone injuries, and wound healing. As research in this area progresses, the demand for sodium alginate is likely to increase.

Academic and research institutions are also contributing to the market demand as they explore new applications and refine existing techniques in 3D bioprinting. The versatility of sodium alginate allows for its use in a wide range of research projects, from basic science to translational medicine.

The food industry has shown interest in 3D bioprinting technologies using sodium alginate for creating novel food textures and structures. This emerging application area could potentially open up new market opportunities and drive demand for sodium alginate in the coming years.

Despite the growing demand, challenges such as the need for standardization in bioink formulations and the complexity of scaling up production processes may impact market growth. However, ongoing research and development efforts are addressing these issues, potentially leading to increased adoption of sodium alginate in 3D bioprinting solutions.

The global market for 3D bioprinting, including materials like sodium alginate, is projected to expand significantly in the coming years. Factors such as increasing investments in research and development, rising prevalence of chronic diseases, and growing awareness of personalized medicine are expected to fuel this growth.

As the technology matures and becomes more accessible, new applications in fields such as cosmetics testing, environmental toxicology, and space medicine are likely to emerge, further driving the demand for sodium alginate in 3D bioprinting solutions. This expanding range of applications underscores the versatility and potential of sodium alginate as a key component in the evolving landscape of bioprinting technologies.

In the pharmaceutical and biotechnology sectors, there is a growing need for more accurate and efficient drug testing platforms. 3D bioprinted tissues and organs using sodium alginate-based bioinks offer a promising alternative to traditional 2D cell cultures and animal models. This shift towards more physiologically relevant testing environments is expected to drive market demand for sodium alginate in bioprinting applications.

The healthcare industry, particularly in the field of regenerative medicine, shows substantial interest in sodium alginate-based 3D bioprinting solutions. The ability to create patient-specific tissue constructs and implants has the potential to revolutionize treatments for various conditions, including cartilage defects, bone injuries, and wound healing. As research in this area progresses, the demand for sodium alginate is likely to increase.

Academic and research institutions are also contributing to the market demand as they explore new applications and refine existing techniques in 3D bioprinting. The versatility of sodium alginate allows for its use in a wide range of research projects, from basic science to translational medicine.

The food industry has shown interest in 3D bioprinting technologies using sodium alginate for creating novel food textures and structures. This emerging application area could potentially open up new market opportunities and drive demand for sodium alginate in the coming years.

Despite the growing demand, challenges such as the need for standardization in bioink formulations and the complexity of scaling up production processes may impact market growth. However, ongoing research and development efforts are addressing these issues, potentially leading to increased adoption of sodium alginate in 3D bioprinting solutions.

The global market for 3D bioprinting, including materials like sodium alginate, is projected to expand significantly in the coming years. Factors such as increasing investments in research and development, rising prevalence of chronic diseases, and growing awareness of personalized medicine are expected to fuel this growth.

As the technology matures and becomes more accessible, new applications in fields such as cosmetics testing, environmental toxicology, and space medicine are likely to emerge, further driving the demand for sodium alginate in 3D bioprinting solutions. This expanding range of applications underscores the versatility and potential of sodium alginate as a key component in the evolving landscape of bioprinting technologies.

Sodium Alginate Challenges

Despite the promising potential of sodium alginate in 3D bioprinting, several challenges hinder its widespread adoption and optimal utilization. One of the primary obstacles is the difficulty in achieving precise control over the gelation process. Sodium alginate's crosslinking mechanism, while advantageous for creating stable structures, can be unpredictable and hard to fine-tune, leading to inconsistencies in the final printed constructs.

Another significant challenge lies in the mechanical properties of sodium alginate-based bioinks. While the material offers good printability, the resulting structures often lack the necessary strength and durability required for certain tissue engineering applications. This limitation restricts the use of sodium alginate in creating load-bearing tissues or structures that need to withstand significant mechanical stress.

The biocompatibility of sodium alginate, although generally considered good, presents its own set of challenges. Some studies have reported potential immunogenic responses to alginate-based materials, particularly when used in long-term implantations. This raises concerns about the material's suitability for certain in vivo applications and necessitates further research into improving its biocompatibility profile.

Scalability and reproducibility pose additional hurdles in sodium alginate integration. The variability in alginate sources and extraction methods can lead to inconsistencies in the final product, making it difficult to standardize bioprinting processes across different batches or laboratories. This lack of uniformity hampers the translation of research findings into clinical applications.

The limited cell adhesion properties of sodium alginate present another challenge. Unlike some other biomaterials, alginate does not naturally promote cell attachment, which can impede cell growth and tissue formation within the printed constructs. This necessitates the development of modified alginate formulations or composite bioinks to enhance cell adhesion and proliferation.

Lastly, the degradation profile of sodium alginate-based constructs remains a concern. The material's breakdown in physiological conditions can be unpredictable, potentially leading to premature structural failure or uncontrolled release of encapsulated cells or bioactive molecules. Achieving a balance between structural integrity and controlled degradation is crucial for successful tissue engineering applications.

Addressing these challenges requires interdisciplinary approaches, combining expertise from materials science, biology, and engineering. Ongoing research focuses on developing novel crosslinking strategies, exploring alginate modifications, and creating composite materials to overcome these limitations and fully harness the potential of sodium alginate in 3D bioprinting solutions.

Another significant challenge lies in the mechanical properties of sodium alginate-based bioinks. While the material offers good printability, the resulting structures often lack the necessary strength and durability required for certain tissue engineering applications. This limitation restricts the use of sodium alginate in creating load-bearing tissues or structures that need to withstand significant mechanical stress.

The biocompatibility of sodium alginate, although generally considered good, presents its own set of challenges. Some studies have reported potential immunogenic responses to alginate-based materials, particularly when used in long-term implantations. This raises concerns about the material's suitability for certain in vivo applications and necessitates further research into improving its biocompatibility profile.

Scalability and reproducibility pose additional hurdles in sodium alginate integration. The variability in alginate sources and extraction methods can lead to inconsistencies in the final product, making it difficult to standardize bioprinting processes across different batches or laboratories. This lack of uniformity hampers the translation of research findings into clinical applications.

The limited cell adhesion properties of sodium alginate present another challenge. Unlike some other biomaterials, alginate does not naturally promote cell attachment, which can impede cell growth and tissue formation within the printed constructs. This necessitates the development of modified alginate formulations or composite bioinks to enhance cell adhesion and proliferation.

Lastly, the degradation profile of sodium alginate-based constructs remains a concern. The material's breakdown in physiological conditions can be unpredictable, potentially leading to premature structural failure or uncontrolled release of encapsulated cells or bioactive molecules. Achieving a balance between structural integrity and controlled degradation is crucial for successful tissue engineering applications.

Addressing these challenges requires interdisciplinary approaches, combining expertise from materials science, biology, and engineering. Ongoing research focuses on developing novel crosslinking strategies, exploring alginate modifications, and creating composite materials to overcome these limitations and fully harness the potential of sodium alginate in 3D bioprinting solutions.

Current Alginate Solutions

01 Use of sodium alginate in cosmetic formulations

Sodium alginate is widely used in cosmetic formulations due to its thickening, stabilizing, and film-forming properties. It can improve the texture and consistency of various cosmetic products, including creams, lotions, and gels. Sodium alginate also helps in moisture retention, making it beneficial for skincare products.- Use of sodium alginate in cosmetic formulations: Sodium alginate is widely used in cosmetic formulations due to its thickening, stabilizing, and film-forming properties. It can improve the texture and consistency of various cosmetic products, including creams, lotions, and gels. Sodium alginate also helps in moisture retention, making it beneficial for skincare products.

- Sodium alginate in drug delivery systems: Sodium alginate is utilized in pharmaceutical applications, particularly in drug delivery systems. It can form hydrogels that encapsulate drugs, allowing for controlled release. This property makes it useful in developing oral, topical, and injectable drug formulations with improved bioavailability and targeted delivery.

- Sodium alginate in wound healing applications: Sodium alginate is employed in wound dressings and healing applications. Its ability to absorb exudates, maintain a moist environment, and promote tissue regeneration makes it valuable in treating various types of wounds, including burns and chronic ulcers. It can also be combined with other materials to enhance wound healing properties.

- Sodium alginate in food and beverage industry: In the food and beverage industry, sodium alginate is used as a thickening agent, stabilizer, and emulsifier. It can improve the texture and mouthfeel of various products, including ice creams, sauces, and beverages. Sodium alginate is also used in molecular gastronomy for creating unique textures and presentations.

- Sodium alginate in 3D bioprinting and tissue engineering: Sodium alginate plays a crucial role in 3D bioprinting and tissue engineering applications. Its biocompatibility and ability to form hydrogels make it suitable for creating scaffolds that support cell growth and tissue formation. This technology has potential applications in regenerative medicine and the development of artificial organs.

02 Sodium alginate in drug delivery systems

Sodium alginate is utilized in pharmaceutical applications, particularly in drug delivery systems. It can form hydrogels that encapsulate drugs, allowing for controlled release. This property makes it useful in developing oral, topical, and injectable drug formulations with improved bioavailability and targeted delivery.Expand Specific Solutions03 Sodium alginate in wound healing applications

Sodium alginate is employed in wound dressings and healing applications due to its biocompatibility and ability to maintain a moist wound environment. It can absorb wound exudates and form a protective gel, promoting faster healing and reducing the risk of infection. Some formulations combine sodium alginate with other materials for enhanced wound care properties.Expand Specific Solutions04 Use of sodium alginate in food industry

In the food industry, sodium alginate is used as a thickening agent, stabilizer, and emulsifier. It can improve the texture and stability of various food products, including ice cream, yogurt, and sauces. Sodium alginate is also used in molecular gastronomy for creating unique food textures and presentations.Expand Specific Solutions05 Sodium alginate in 3D bioprinting and tissue engineering

Sodium alginate is increasingly used in 3D bioprinting and tissue engineering applications. Its ability to form hydrogels that can encapsulate cells makes it suitable for creating scaffolds and structures for tissue regeneration. Researchers are exploring its potential in developing artificial organs and personalized medicine approaches.Expand Specific Solutions

Key 3D Bioprinting Players

The integration of sodium alginate in 3D bioprinting solutions is in a rapidly evolving phase, with the market showing significant growth potential. The technology is advancing from early-stage development to more mature applications, driven by increasing demand in tissue engineering and regenerative medicine. Key players like BICO Group AB and Shenzhen Ouma Biotechnology Co., Ltd. are at the forefront, developing innovative solutions. Research institutions such as King Abdullah University of Science & Technology and the University of Bristol are contributing to technological advancements. The market is characterized by a mix of established companies and emerging startups, indicating a competitive and dynamic landscape with ample opportunities for further innovation and market expansion.

The Shenzhen Institutes of Advanced Technology

Technical Solution: The Shenzhen Institutes of Advanced Technology (SIAT) has made significant advancements in sodium alginate integration for 3D bioprinting. Their research focuses on developing novel composite bioinks that combine sodium alginate with other biomaterials to enhance printability and biological performance. SIAT has pioneered a method of incorporating nanoparticles into alginate-based bioinks, improving mechanical strength and cell adhesion properties[5]. They have also developed a unique crosslinking strategy that allows for precise control over the gelation kinetics of sodium alginate, enabling the creation of gradient structures within printed constructs[6]. SIAT's bioprinting platform incorporates real-time monitoring of the crosslinking process, ensuring optimal printing conditions and construct integrity[7].

Strengths: Advanced composite bioink formulations, precise control over crosslinking, and innovative nanoparticle integration. Weaknesses: Potential scalability challenges and the need for specialized equipment for some of their advanced techniques.

BICO Group AB

Technical Solution: BICO Group AB has developed advanced 3D bioprinting solutions incorporating sodium alginate. Their technology utilizes a multi-material bioprinting approach, allowing for the creation of complex tissue-like structures. The company's CELLINK bioinks, which include sodium alginate-based formulations, provide excellent printability and cell viability[1]. BICO's bioprinters, such as the BIO X series, offer precise control over printing parameters, enabling the fabrication of intricate structures with varying mechanical properties[2]. The integration of sodium alginate in their bioinks allows for rapid crosslinking, resulting in stable constructs that can maintain their shape during and after printing[3]. BICO has also developed specialized nozzles and printheads optimized for alginate-based bioinks, ensuring consistent extrusion and high-resolution printing[4].

Strengths: Versatile multi-material printing capabilities, excellent biocompatibility, and rapid crosslinking for structural stability. Weaknesses: Potential limitations in long-term mechanical properties and the need for post-processing steps for some applications.

Alginate Innovations

A sodium alginate, gelatin, collagen and fibrin (AGCF) based bio-ink for the bioprinting of a 3D biogel-based tissue/structure

PatentWO2022153319A1

Innovation

- A bio-ink comprising sodium alginate, gelatin, collagen, and fibrinogen, with specific ratios and preparation methods, including crosslinking agents like thrombin and calcium, to create a stable 3D biogel structure that promotes cell proliferation and viability.

Process to obtain three-dimensional biodressing, three- dimensional biodressing obtained and its use

PatentPendingUS20250073371A1

Innovation

- A process involving the use of mesenchymal cells derived from the human umbilical cord or adipose tissue, cultured in xenoantigen-free human AB serum, combined with 4% sodium alginate, and produced through 3D bioprinting, where the calcium chloride solution is applied after a 5-15 minute pause post-bioprinting to enhance maturation and prevent deformation.

Regulatory Considerations

The integration of sodium alginate in 3D bioprinting solutions necessitates careful consideration of regulatory frameworks to ensure compliance and safety. As this technology advances, regulatory bodies worldwide are adapting their guidelines to address the unique challenges posed by bioprinted materials and structures. The U.S. Food and Drug Administration (FDA) has been at the forefront of developing regulatory pathways for 3D-printed medical devices, including those incorporating biomaterials like sodium alginate.

One of the primary regulatory considerations is the classification of sodium alginate-based bioprinted products. Depending on their intended use and level of risk, these products may fall under different regulatory categories, such as medical devices, biologics, or combination products. This classification determines the specific regulatory requirements and approval processes that manufacturers must follow.

Safety and efficacy evaluations form a crucial part of the regulatory process. Manufacturers must demonstrate that their sodium alginate-based bioprinted products are safe for their intended use and perform as claimed. This involves comprehensive testing, including biocompatibility assessments, mechanical property evaluations, and long-term stability studies. The unique nature of 3D bioprinting may require the development of new testing methodologies to adequately assess these products.

Quality control and manufacturing standards are another critical aspect of regulatory compliance. Good Manufacturing Practices (GMP) must be adhered to throughout the production process, from raw material sourcing to final product packaging. For sodium alginate-based bioprints, this includes ensuring consistent material properties, maintaining sterility, and implementing robust quality management systems.

Traceability and documentation are essential components of regulatory compliance. Manufacturers must maintain detailed records of the entire production process, including material sourcing, printing parameters, and post-processing steps. This documentation is crucial for regulatory audits and potential product recalls.

As the field of 3D bioprinting evolves, regulatory bodies are likely to refine their guidelines and requirements. Manufacturers and researchers working with sodium alginate in bioprinting applications must stay informed about these regulatory developments and engage in proactive dialogue with regulatory agencies. This collaborative approach can help shape future regulations and ensure that they are both effective in protecting public health and conducive to innovation in the field.

One of the primary regulatory considerations is the classification of sodium alginate-based bioprinted products. Depending on their intended use and level of risk, these products may fall under different regulatory categories, such as medical devices, biologics, or combination products. This classification determines the specific regulatory requirements and approval processes that manufacturers must follow.

Safety and efficacy evaluations form a crucial part of the regulatory process. Manufacturers must demonstrate that their sodium alginate-based bioprinted products are safe for their intended use and perform as claimed. This involves comprehensive testing, including biocompatibility assessments, mechanical property evaluations, and long-term stability studies. The unique nature of 3D bioprinting may require the development of new testing methodologies to adequately assess these products.

Quality control and manufacturing standards are another critical aspect of regulatory compliance. Good Manufacturing Practices (GMP) must be adhered to throughout the production process, from raw material sourcing to final product packaging. For sodium alginate-based bioprints, this includes ensuring consistent material properties, maintaining sterility, and implementing robust quality management systems.

Traceability and documentation are essential components of regulatory compliance. Manufacturers must maintain detailed records of the entire production process, including material sourcing, printing parameters, and post-processing steps. This documentation is crucial for regulatory audits and potential product recalls.

As the field of 3D bioprinting evolves, regulatory bodies are likely to refine their guidelines and requirements. Manufacturers and researchers working with sodium alginate in bioprinting applications must stay informed about these regulatory developments and engage in proactive dialogue with regulatory agencies. This collaborative approach can help shape future regulations and ensure that they are both effective in protecting public health and conducive to innovation in the field.

Biocompatibility Assessment

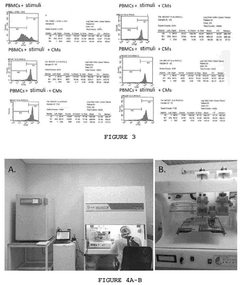

Biocompatibility assessment is a critical aspect of integrating sodium alginate into 3D bioprinting solutions. This evaluation process ensures that the material is safe for use in biological systems and does not elicit adverse reactions when in contact with living tissues. The assessment typically involves a series of in vitro and in vivo tests to determine the material's compatibility with cells, tissues, and the overall physiological environment.

Initial biocompatibility testing of sodium alginate in 3D bioprinting applications often begins with cytotoxicity assays. These tests evaluate the material's potential to cause cell death or inhibit cell growth. Researchers commonly employ standardized methods such as the MTT assay or the Live/Dead assay to quantify cell viability and proliferation in the presence of sodium alginate. Results from these studies have generally shown that sodium alginate exhibits low cytotoxicity, making it a promising candidate for bioprinting applications.

Further biocompatibility assessment includes examining the inflammatory response to sodium alginate-based constructs. This involves analyzing the production of pro-inflammatory cytokines and the activation of immune cells when exposed to the material. Studies have demonstrated that sodium alginate typically elicits a minimal inflammatory response, which is crucial for its successful integration in bioprinted tissues.

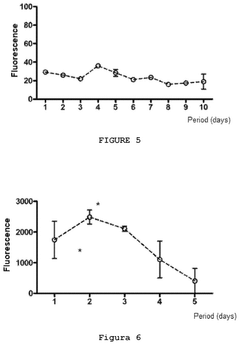

The degradation profile of sodium alginate is another important aspect of biocompatibility assessment. Researchers investigate the rate and products of alginate breakdown in physiological conditions to ensure that the degradation process does not produce harmful byproducts or cause unexpected changes in the local environment. The controlled degradation of sodium alginate scaffolds can be advantageous in tissue engineering applications, allowing for gradual replacement by native tissue.

Genotoxicity and mutagenicity tests are also conducted to assess any potential genetic damage caused by sodium alginate or its degradation products. These tests typically involve bacterial reverse mutation assays (Ames test) and in vitro mammalian cell gene mutation assays. To date, sodium alginate has shown no significant genotoxic or mutagenic effects, further supporting its biocompatibility.

Long-term biocompatibility studies are essential to evaluate the material's performance over extended periods. These studies often involve implantation of sodium alginate-based constructs in animal models, followed by histological analysis and functional assessments. Such investigations help researchers understand the material's integration with host tissues, vascularization potential, and any long-term effects on organ function.

In the context of 3D bioprinting, biocompatibility assessment also considers the material's behavior during and after the printing process. This includes evaluating any changes in the alginate's properties due to crosslinking methods or the incorporation of cells and other bioactive components. The assessment ensures that the bioprinting process itself does not compromise the material's biocompatibility or the viability of encapsulated cells.

Initial biocompatibility testing of sodium alginate in 3D bioprinting applications often begins with cytotoxicity assays. These tests evaluate the material's potential to cause cell death or inhibit cell growth. Researchers commonly employ standardized methods such as the MTT assay or the Live/Dead assay to quantify cell viability and proliferation in the presence of sodium alginate. Results from these studies have generally shown that sodium alginate exhibits low cytotoxicity, making it a promising candidate for bioprinting applications.

Further biocompatibility assessment includes examining the inflammatory response to sodium alginate-based constructs. This involves analyzing the production of pro-inflammatory cytokines and the activation of immune cells when exposed to the material. Studies have demonstrated that sodium alginate typically elicits a minimal inflammatory response, which is crucial for its successful integration in bioprinted tissues.

The degradation profile of sodium alginate is another important aspect of biocompatibility assessment. Researchers investigate the rate and products of alginate breakdown in physiological conditions to ensure that the degradation process does not produce harmful byproducts or cause unexpected changes in the local environment. The controlled degradation of sodium alginate scaffolds can be advantageous in tissue engineering applications, allowing for gradual replacement by native tissue.

Genotoxicity and mutagenicity tests are also conducted to assess any potential genetic damage caused by sodium alginate or its degradation products. These tests typically involve bacterial reverse mutation assays (Ames test) and in vitro mammalian cell gene mutation assays. To date, sodium alginate has shown no significant genotoxic or mutagenic effects, further supporting its biocompatibility.

Long-term biocompatibility studies are essential to evaluate the material's performance over extended periods. These studies often involve implantation of sodium alginate-based constructs in animal models, followed by histological analysis and functional assessments. Such investigations help researchers understand the material's integration with host tissues, vascularization potential, and any long-term effects on organ function.

In the context of 3D bioprinting, biocompatibility assessment also considers the material's behavior during and after the printing process. This includes evaluating any changes in the alginate's properties due to crosslinking methods or the incorporation of cells and other bioactive components. The assessment ensures that the bioprinting process itself does not compromise the material's biocompatibility or the viability of encapsulated cells.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!