Zirconia's Benefits in Chemical Plant Machinery

Zirconia in Chemical Plants: Background and Objectives

Zirconia, a remarkable ceramic material, has been gaining significant attention in the chemical industry due to its exceptional properties and potential applications in plant machinery. The evolution of zirconia technology can be traced back to the early 20th century when it was first discovered as a naturally occurring mineral. However, it wasn't until the 1960s that researchers began to explore its potential for industrial applications.

The development of zirconia technology has been driven by the increasing demand for materials that can withstand harsh chemical environments, high temperatures, and mechanical stress. In chemical plants, where corrosive substances and extreme conditions are commonplace, the need for durable and reliable machinery components has become paramount. This has led to a growing interest in zirconia as a potential solution to many of the challenges faced in chemical processing equipment.

The primary objective of researching zirconia's benefits in chemical plant machinery is to enhance the performance, longevity, and safety of critical components. By leveraging zirconia's unique properties, such as its high strength, excellent wear resistance, and chemical inertness, researchers aim to develop innovative solutions that can revolutionize the design and operation of chemical processing equipment.

One of the key trends in zirconia technology is the development of advanced manufacturing techniques, such as 3D printing and precision machining, which allow for the creation of complex geometries and customized components. This has opened up new possibilities for integrating zirconia into various parts of chemical plant machinery, including valves, pumps, and reactor vessels.

Another important aspect of zirconia research is the exploration of its potential to improve energy efficiency in chemical processes. The material's low thermal conductivity and high thermal stability make it an attractive option for insulation and heat management applications, potentially leading to significant energy savings in chemical plants.

As the chemical industry continues to evolve and face new challenges, such as stricter environmental regulations and the need for more sustainable processes, the role of advanced materials like zirconia becomes increasingly crucial. Researchers are now focusing on developing zirconia-based composites and coatings that can further enhance its properties and expand its range of applications in chemical plant machinery.

The ongoing research into zirconia's benefits is expected to yield significant advancements in chemical plant design and operation, ultimately leading to improved safety, efficiency, and productivity in the industry. As we delve deeper into the potential of this remarkable material, it is clear that zirconia will play a pivotal role in shaping the future of chemical processing technology.

Market Demand Analysis for Zirconia-Enhanced Machinery

The market demand for zirconia-enhanced machinery in chemical plants has been steadily increasing over the past decade. This growth is primarily driven by the unique properties of zirconia, which offer significant advantages in harsh chemical environments. Chemical plant operators are increasingly recognizing the potential of zirconia to enhance the durability, efficiency, and safety of their equipment.

One of the key factors fueling market demand is the growing emphasis on operational efficiency and cost reduction in the chemical industry. Zirconia-enhanced machinery components, such as valves, pumps, and reactors, demonstrate superior resistance to corrosion, wear, and thermal shock. This translates to longer equipment lifespan, reduced maintenance requirements, and fewer production interruptions, ultimately leading to substantial cost savings for chemical plant operators.

The market for zirconia-enhanced machinery is also being propelled by stringent safety and environmental regulations in the chemical industry. Zirconia's exceptional chemical inertness and stability make it an ideal material for handling aggressive chemicals and preventing contamination. This aligns well with the industry's focus on minimizing environmental impact and ensuring product purity.

Another significant driver of market demand is the push for process intensification in chemical manufacturing. Zirconia's high thermal conductivity and mechanical strength allow for the design of more compact and efficient reactors and heat exchangers. This enables chemical plants to achieve higher throughput and improved energy efficiency, meeting the industry's goals for increased productivity and sustainability.

The oil and gas sector, a major segment of the chemical industry, has shown particular interest in zirconia-enhanced machinery. The material's resistance to sulfide stress cracking and hydrogen embrittlement makes it highly valuable in offshore and deep-sea applications, where equipment is exposed to extreme conditions.

Geographically, the demand for zirconia-enhanced machinery is strongest in regions with a robust chemical manufacturing base, such as North America, Europe, and Asia-Pacific. Emerging economies in Asia, particularly China and India, are expected to be key growth markets due to their rapidly expanding chemical industries and increasing focus on technological advancements.

Looking ahead, the market for zirconia-enhanced machinery in chemical plants is projected to continue its growth trajectory. Factors such as the ongoing development of advanced zirconia composites, the increasing adoption of Industry 4.0 technologies, and the growing emphasis on sustainable manufacturing practices are expected to further drive demand. As chemical companies seek to optimize their operations and stay competitive in a challenging global market, the adoption of zirconia-enhanced machinery is likely to accelerate, opening up new opportunities for equipment manufacturers and material suppliers alike.

Current State and Challenges of Zirconia Applications

Zirconia has gained significant traction in chemical plant machinery applications due to its exceptional properties. Currently, zirconia is widely used in various components of chemical processing equipment, including valves, pumps, and reactors. Its high strength, excellent corrosion resistance, and thermal stability make it an ideal material for harsh chemical environments.

The current state of zirconia applications in chemical plant machinery is characterized by continuous advancements in material science and manufacturing techniques. Researchers and engineers are focusing on developing new zirconia composites and coatings to enhance its performance further. These innovations aim to improve wear resistance, reduce friction, and extend the lifespan of critical components in chemical processing equipment.

Despite its widespread adoption, zirconia applications in chemical plant machinery face several challenges. One of the primary concerns is the material's brittleness, which can lead to sudden failure under certain conditions. This limitation necessitates careful design considerations and regular maintenance to prevent catastrophic failures in high-stress applications.

Another challenge is the high cost associated with zirconia components compared to traditional materials. While the long-term benefits often justify the initial investment, the higher upfront costs can be a barrier to adoption for some chemical plants, particularly smaller operations with limited budgets.

The manufacturing process for complex zirconia components also presents challenges. Achieving precise dimensions and intricate geometries can be difficult due to the material's hardness and resistance to machining. This limitation can restrict the design possibilities for certain chemical plant machinery components.

Researchers are actively working to address these challenges through various approaches. One promising avenue is the development of zirconia-based composites that combine the material's beneficial properties with those of other materials to mitigate its limitations. For example, incorporating ceramic fibers or nanoparticles into zirconia matrices can improve toughness and reduce brittleness.

Advancements in additive manufacturing techniques, such as 3D printing of zirconia components, are also showing potential in overcoming some of the manufacturing challenges. These methods allow for the creation of complex geometries that were previously difficult or impossible to achieve with traditional manufacturing processes.

In conclusion, while zirconia has established itself as a valuable material in chemical plant machinery, there are still significant opportunities for improvement and innovation. Overcoming the current challenges will likely lead to even broader adoption and new applications in the chemical processing industry.

Existing Zirconia Solutions for Chemical Plant Equipment

01 Dental applications of zirconia

Zirconia offers significant benefits in dental applications due to its biocompatibility, strength, and aesthetic properties. It is widely used for dental implants, crowns, and bridges, providing a durable and natural-looking alternative to traditional materials. Zirconia's resistance to wear and fracture makes it an ideal choice for long-lasting dental restorations.- Dental applications of zirconia: Zirconia is widely used in dental applications due to its excellent biocompatibility, strength, and aesthetic properties. It is used for dental implants, crowns, bridges, and other prosthetic devices. Zirconia's durability and natural appearance make it an ideal material for long-lasting dental restorations.

- Mechanical properties and durability: Zirconia exhibits exceptional mechanical properties, including high strength, toughness, and wear resistance. These characteristics make it suitable for various industrial applications, such as cutting tools, bearings, and structural components. The material's durability contributes to extended product lifespans and improved performance in demanding environments.

- Thermal insulation and heat resistance: Zirconia possesses excellent thermal insulation properties and high heat resistance. These attributes make it valuable in applications requiring protection from extreme temperatures, such as thermal barrier coatings for gas turbines, furnace linings, and heat shields for aerospace components.

- Optical and electronic applications: Zirconia's unique optical and electronic properties make it suitable for various high-tech applications. It is used in optical fibers, laser components, and solid oxide fuel cells. The material's high refractive index and transparency in certain forms contribute to its versatility in optical and electronic devices.

- Chemical stability and corrosion resistance: Zirconia exhibits excellent chemical stability and corrosion resistance, making it valuable in harsh chemical environments. It is used in chemical processing equipment, sensors, and protective coatings. The material's resistance to acids, alkalis, and other corrosive substances enhances the longevity and reliability of components in challenging industrial settings.

02 Mechanical properties and durability

Zirconia exhibits exceptional mechanical properties, including high strength, toughness, and hardness. These characteristics make it suitable for various industrial applications where durability and wear resistance are crucial. Zirconia components can withstand extreme conditions and maintain their structural integrity over extended periods.Expand Specific Solutions03 Thermal insulation and heat resistance

Zirconia's low thermal conductivity and high melting point make it an excellent material for thermal insulation and heat-resistant applications. It is used in thermal barrier coatings, furnace linings, and other high-temperature environments where maintaining thermal stability is critical.Expand Specific Solutions04 Optical and electronic applications

Zirconia's unique optical properties, including high refractive index and transparency in certain forms, make it valuable in optical and electronic applications. It is used in optical fibers, laser components, and as a substrate material for electronic devices, offering improved performance and durability.Expand Specific Solutions05 Environmental and energy applications

Zirconia plays a significant role in environmental and energy-related applications. It is used in oxygen sensors, fuel cells, and catalytic converters, contributing to improved energy efficiency and reduced emissions. Zirconia's chemical stability and ionic conductivity make it suitable for various clean energy technologies.Expand Specific Solutions

Key Players in Zirconia Manufacturing and Implementation

The research on zirconia's benefits in chemical plant machinery is in a mature development stage, with a growing market size driven by increasing demand for corrosion-resistant materials in harsh chemical environments. The technology has reached a high level of maturity, with established players like 3M Innovative Properties Co., Saint-Gobain Centre de Recherches et d'Études Européen SAS, and Corning, Inc. leading the field. These companies have extensive experience in developing and implementing zirconia-based solutions for chemical plant applications. Emerging players such as Dalian University of Technology and Nanjing University are contributing to further advancements in zirconia technology, focusing on novel applications and improved performance characteristics. The competitive landscape is characterized by ongoing research and development efforts to enhance zirconia's properties and expand its use in various chemical processing equipment.

3M Innovative Properties Co.

Corning, Inc.

Core Innovations in Zirconia Material Science

- The development of thin, penetrating coatings of rare earth and transition metal oxides, such as ceria and zirconia, applied via a liquid metal carboxylate solution that converts to metal oxides at low temperatures, providing a stable and durable catalytic surface for oxidation and combustion support.

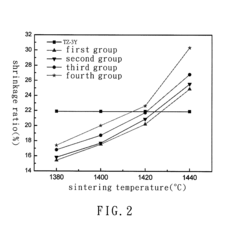

- A method involving wet mixing of silicon-containing zirconia powder with sodium carbonate and tetraethoxysilane, followed by calcination at reduced temperatures (900-1200°C) and subsequent sintering at 1415-1450°C to produce a silicon-containing zirconia calcined and sintered body with increased compactness and structural strength.

Environmental Impact of Zirconia in Industrial Processes

The integration of zirconia in chemical plant machinery has significant environmental implications, both positive and negative. On the positive side, zirconia's exceptional durability and resistance to corrosion contribute to extended equipment lifespans, reducing the frequency of replacements and associated waste generation. This longevity translates to decreased resource consumption and energy expenditure in manufacturing replacement parts, ultimately lowering the overall carbon footprint of chemical plant operations.

Furthermore, zirconia's thermal insulation properties enhance energy efficiency in high-temperature processes. By minimizing heat loss, zirconia-based components reduce the energy requirements for maintaining optimal operating temperatures, leading to decreased fuel consumption and greenhouse gas emissions. This improved thermal management also contributes to more stable and controlled reactions, potentially reducing the occurrence of unwanted by-products and waste streams.

However, the environmental impact of zirconia production itself must be considered. The extraction and processing of zirconium ores involve energy-intensive operations and potential habitat disruption. The refining process to obtain high-purity zirconia also requires substantial energy inputs and may generate hazardous waste materials. These factors necessitate a comprehensive life cycle assessment to accurately gauge the net environmental benefit of zirconia use in chemical plant machinery.

In terms of emissions control, zirconia-based sensors and catalysts play a crucial role in monitoring and reducing harmful pollutants. Zirconia oxygen sensors enable precise combustion control in industrial furnaces, optimizing fuel efficiency and minimizing emissions. Additionally, zirconia-supported catalysts enhance the efficiency of various chemical processes, potentially reducing the formation of environmentally harmful by-products.

The use of zirconia in chemical plant machinery also impacts water management. Its corrosion resistance allows for the handling of aggressive chemicals and waste streams with reduced risk of leaks or equipment failure, thereby minimizing the potential for environmental contamination. This property is particularly valuable in wastewater treatment processes within chemical plants, where zirconia-based components can withstand harsh conditions while maintaining operational integrity.

As the chemical industry moves towards more sustainable practices, the role of zirconia in enabling cleaner production processes becomes increasingly significant. Its ability to withstand extreme conditions allows for the development of more efficient and environmentally friendly chemical reactions, potentially reducing the reliance on harmful solvents or reagents. However, the end-of-life management of zirconia-containing equipment presents challenges, as the material's durability also makes it difficult to recycle or dispose of in an environmentally responsible manner.

Cost-Benefit Analysis of Zirconia Integration

The integration of zirconia into chemical plant machinery represents a significant investment decision that requires careful cost-benefit analysis. Initial costs associated with zirconia implementation are typically higher than traditional materials due to its advanced manufacturing processes and specialized handling requirements. However, the long-term benefits often outweigh these upfront expenses.

Zirconia's exceptional wear resistance and corrosion resistance contribute to extended equipment lifespan, reducing the frequency and costs of replacements. This durability translates into decreased downtime for maintenance and repairs, enhancing overall plant productivity. The material's thermal insulation properties can also lead to energy savings in high-temperature applications, potentially lowering operational costs over time.

In terms of performance, zirconia's superior mechanical properties allow for the design of more efficient and compact machinery. This can result in space savings within the plant and potentially increased throughput. The material's chemical inertness reduces the risk of contamination in sensitive processes, which can lead to improved product quality and fewer rejected batches, thereby increasing profitability.

Safety considerations also factor into the cost-benefit equation. Zirconia's resistance to chemical attack and thermal shock reduces the risk of catastrophic failures, potentially lowering insurance premiums and mitigating the costs associated with workplace accidents or environmental incidents.

However, the analysis must account for potential challenges. The higher initial investment may strain short-term budgets, and there may be a learning curve associated with implementing new zirconia-based equipment. Additionally, while zirconia is highly durable, when replacement is eventually needed, it may be more costly than traditional materials.

To quantify the benefits, companies should consider metrics such as Total Cost of Ownership (TCO) over the expected lifetime of the equipment, factoring in initial costs, operational savings, maintenance reductions, and potential revenue increases from improved performance. Return on Investment (ROI) calculations should extend beyond immediate financial returns to include less tangible benefits such as improved safety records and environmental compliance.

In conclusion, while the upfront costs of zirconia integration may be substantial, the long-term benefits in terms of durability, efficiency, safety, and product quality often justify the investment for chemical plants seeking to optimize their operations and maintain a competitive edge in the industry.