Using Additive Manufacturing For Turbine Engines To Improve Performance

DEC 5, 20244 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Technology Background and Goals

Additive manufacturing, also known as 3D printing, has emerged as a promising technology for the production of turbine engine components. The primary objective of this research is to explore the potential of using additive manufacturing to improve the performance of turbine engines.

Additive manufacturing offers several advantages over traditional manufacturing methods, including the ability to create complex geometries, reduce material waste, and enable lightweight designs. By leveraging these capabilities, turbine engine components can be optimized for improved aerodynamic performance, increased fuel efficiency, and reduced emissions. Additionally, additive manufacturing allows for the integration of multiple parts into a single component, simplifying assembly and reducing the overall weight of the engine.

Additive manufacturing offers several advantages over traditional manufacturing methods, including the ability to create complex geometries, reduce material waste, and enable lightweight designs. By leveraging these capabilities, turbine engine components can be optimized for improved aerodynamic performance, increased fuel efficiency, and reduced emissions. Additionally, additive manufacturing allows for the integration of multiple parts into a single component, simplifying assembly and reducing the overall weight of the engine.

Market Demand Analysis

- Aerospace Industry Demand

Additive manufacturing (AM) has significant potential in the aerospace industry, particularly for turbine engine components. The demand is driven by the need for lightweight, high-performance parts with complex geometries that are difficult to produce using traditional manufacturing methods. - Cost Reduction

AM can reduce manufacturing costs by minimizing material waste, enabling on-demand production, and reducing the need for tooling and inventory. This cost-effectiveness is particularly attractive for low-volume, high-value components. - Design Flexibility

AM allows for greater design freedom, enabling the creation of intricate geometries and internal features that are challenging or impossible to achieve with conventional manufacturing techniques. This flexibility can lead to improved performance and efficiency. - Repair and Maintenance

AM can be used for repair and maintenance applications, such as producing replacement parts on-demand, reducing downtime and extending the lifespan of turbine engines. - Customization and Personalization

AM enables the production of customized and personalized components, catering to specific requirements or individual needs. This can be advantageous in niche markets or for specialized applications.

Technology Status and Challenges

- Material Limitations

Current additive manufacturing (AM) materials have limited mechanical properties, such as strength, ductility, and fatigue resistance, compared to traditional manufacturing methods. This poses challenges for high-performance applications like turbine engines. - Process Inconsistencies

AM processes can suffer from inconsistencies in part quality due to factors like powder quality, environmental conditions, and process parameter variations. This can lead to defects and performance issues in critical components. - Design Constraints

The design freedom offered by AM is still limited by factors like support structure requirements, part orientation, and post-processing needs. These constraints can restrict the full potential of AM for complex geometries. - Qualification and Certification

Establishing robust qualification and certification processes for AM-produced parts, especially for safety-critical applications like turbine engines, remains a significant challenge due to the complexity and variability of AM processes. - Cost and Scalability

While AM offers advantages in customization and design flexibility, the high costs of materials, equipment, and post-processing can limit its widespread adoption, especially for large-scale production.

Current Technical Solutions

01 Turbine engine performance optimization

Various techniques for optimizing turbine engine performance, such as adjusting operating parameters, modifying component designs, or implementing control systems to improve efficiency, reduce emissions, or enhance overall performance.- Turbine engine performance optimization: Techniques for optimizing turbine engine performance, including adjusting operating parameters, modifying component designs, and implementing control systems to improve efficiency, reduce emissions, and enhance overall performance.

- Turbine blade design and cooling: Improved turbine blade designs and cooling mechanisms to increase durability, efficiency, and allow higher operating temperatures for better engine performance.

- Combustion system optimization: Optimizing combustion systems through modifications to combustor design, fuel injection systems, and advanced combustion control strategies for improved performance, reduced emissions, and increased efficiency.

- Turbine engine control systems: Advanced control systems with sensors, algorithms, and actuators to monitor and adjust engine parameters in real-time for optimal operation under varying conditions.

- Turbine engine component design and materials: Advancements in materials and component designs for compressors, combustors, and turbines to improve durability, efficiency, and overall engine performance.

02 Turbine blade design and cooling

Improved turbine blade designs and cooling mechanisms to increase durability and efficiency, allowing for higher operating temperatures and better overall engine performance.Expand Specific Solutions03 Combustion system optimization

Optimizing combustion systems through modifications to combustor design, fuel injection systems, or advanced combustion control strategies for improved performance, reduced emissions, and increased fuel efficiency.Expand Specific Solutions04 Turbine engine control systems

Advanced control systems with sensors, algorithms, and actuators to monitor and adjust engine parameters in real-time for optimal operation under varying conditions.Expand Specific Solutions05 Turbine engine component design and materials

Advancements in materials science and component design for compressors, combustors, and turbines to improve durability, efficiency, and overall engine performance.Expand Specific Solutions

Main Players Analysis

The research on using additive manufacturing for turbine engines to improve performance is a rapidly evolving field, attracting significant interest from major industry players. While the technology is still in its early stages, it holds immense potential for enhancing engine performance and efficiency.

RTX Corp.

Technical Solution: RTX has developed techniques for 3D printing turbine blades and vanes using powder bed fusion processes, aiming to improve engine performance through optimized cooling channels and reduced weight.

Strengths: Strong aerospace manufacturing capabilities, extensive experience in turbine engine design. Weaknesses: Potential challenges in scaling up additive manufacturing processes, intellectual property disputes.

General Electric Company

Technical Solution: GE has developed techniques for 3D printing complex fuel nozzles and other intricate parts using DMLM and EBM processes, enabling weight reduction and improved performance.

Strengths: Extensive resources and expertise in turbine engine design and manufacturing, vertically integrated supply chain. Weaknesses: Potential challenges in scaling up additive manufacturing processes, intellectual property disputes.

Key Technology Interpretation

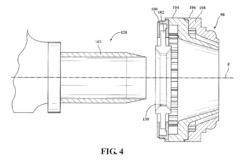

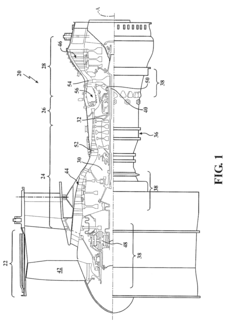

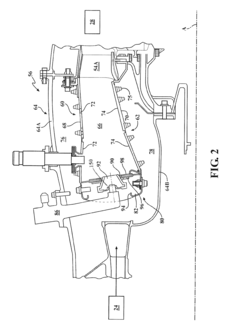

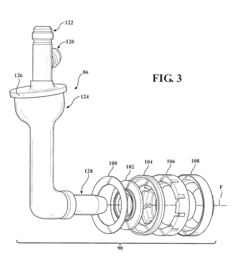

Additvely manufactured swirler mount interface for gas turbine engine combustor

PatentActiveEP2966357A1

Innovation

- The use of additively manufactured wear surfaces, which are designed to extend the lifespan of the combustor components and reduce material degradation. this allows for more efficient and cost-effective manufacturing processes, as well as the potential for improved performance and durability of the combustor.

Additive Manufacturing Regulatory Landscape

The regulatory landscape surrounding additive manufacturing (AM) for turbine engines is complex and evolving. Governments and industry bodies worldwide are actively developing standards and guidelines to ensure the safety, quality, and reliability of AM components in critical applications like aviation. Key areas of focus include material qualification, process validation, non-destructive testing, and quality assurance protocols.

In the United States, the Federal Aviation Administration (FAA) has established a roadmap for certifying AM parts for aircraft, outlining requirements for design, production, and continued airworthiness. The FAA collaborates closely with organizations like ASTM International and SAE International to develop industry-wide standards. Similarly, the European Union Aviation Safety Agency (EASA) has issued regulations and guidance material for AM in aviation, emphasizing the importance of robust quality management systems.

International organizations like the International Civil Aviation Organization (ICAO) and the International Organization for Standardization (ISO) are also playing a crucial role in harmonizing AM regulations globally. The ISO/ASTM 52900 series of standards provides a comprehensive framework for AM processes, materials, and test methods, facilitating cross-border collaboration and trade in AM components.

In the United States, the Federal Aviation Administration (FAA) has established a roadmap for certifying AM parts for aircraft, outlining requirements for design, production, and continued airworthiness. The FAA collaborates closely with organizations like ASTM International and SAE International to develop industry-wide standards. Similarly, the European Union Aviation Safety Agency (EASA) has issued regulations and guidance material for AM in aviation, emphasizing the importance of robust quality management systems.

International organizations like the International Civil Aviation Organization (ICAO) and the International Organization for Standardization (ISO) are also playing a crucial role in harmonizing AM regulations globally. The ISO/ASTM 52900 series of standards provides a comprehensive framework for AM processes, materials, and test methods, facilitating cross-border collaboration and trade in AM components.

Additive Manufacturing Environmental Impact Assessment

Additive manufacturing (AM), also known as 3D printing, has the potential to revolutionize the production of turbine engine components. By enabling the creation of complex geometries and optimized designs, AM can lead to improved performance, increased efficiency, and reduced emissions. However, it is crucial to assess the environmental impact of this technology throughout its lifecycle.

The environmental impact assessment should encompass the entire AM process, from raw material extraction and processing to component manufacturing, use, and end-of-life disposal or recycling. Key factors to consider include energy consumption, greenhouse gas emissions, waste generation, and resource depletion. Additionally, the potential for material and energy savings through optimized designs and reduced waste should be evaluated.

Furthermore, the assessment should examine the environmental implications of different AM technologies, such as powder bed fusion, directed energy deposition, and material extrusion. Each technology may have unique environmental considerations, including the type of materials used, energy requirements, and waste streams generated. Comparative analyses with traditional manufacturing methods can provide valuable insights into the relative environmental impact of AM for turbine engine components.

The environmental impact assessment should encompass the entire AM process, from raw material extraction and processing to component manufacturing, use, and end-of-life disposal or recycling. Key factors to consider include energy consumption, greenhouse gas emissions, waste generation, and resource depletion. Additionally, the potential for material and energy savings through optimized designs and reduced waste should be evaluated.

Furthermore, the assessment should examine the environmental implications of different AM technologies, such as powder bed fusion, directed energy deposition, and material extrusion. Each technology may have unique environmental considerations, including the type of materials used, energy requirements, and waste streams generated. Comparative analyses with traditional manufacturing methods can provide valuable insights into the relative environmental impact of AM for turbine engine components.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!