Thrust Bearings With High Measurement Accuracy

Thrust Bearings Technology Background And Goals

Thrust bearings with high measurement accuracy are crucial components in various industrial applications, enabling precise control and monitoring of rotational systems. The primary objective of this research is to explore innovative solutions that enhance the measurement accuracy of thrust bearings, addressing the growing demand for higher precision in sectors like aerospace, precision manufacturing, and scientific instrumentation.

This section delves into the current technological landscape, identifying the key challenges and limitations hindering the achievement of high measurement accuracy in thrust bearings. It examines the fundamental principles and design considerations that influence measurement precision, such as material selection, sensor integration, and signal processing techniques. By thoroughly understanding the existing technological barriers, this research aims to pave the way for groundbreaking advancements that can revolutionize the performance and reliability of thrust bearing systems.

Thrust Bearings Market Demand Analysis

- Market Size and Growth

The global thrust bearings market is expected to witness significant growth, driven by the increasing demand from various industries such as aerospace, automotive, and industrial machinery. The market size is projected to reach $X billion by 20XX, growing at a CAGR of X% during the forecast period. - Key Application Areas

Thrust bearings find extensive applications in industries where rotary motion and heavy axial loads are involved. The major application areas include:- Aerospace and aviation (turbines, engines, rotors)

- Automotive (transmissions, gearboxes, wheels)

- Industrial machinery (pumps, compressors, conveyors)

- Power generation (wind turbines, generators)

- Demand Drivers

- Increasing demand for high-performance and energy-efficient machinery

- Growing emphasis on precision and reliability in critical applications

- Expansion of industries like aerospace, automotive, and renewable energy

- Replacement and maintenance requirements in existing installations

- Regional Trends

The Asia-Pacific region is expected to be the fastest-growing market for thrust bearings, driven by the rapid industrialization and infrastructure development in countries like China and India. North America and Europe also hold significant market shares due to the presence of established industries and stringent quality standards.

Thrust Bearings Technology Status And Challenges

- Thrust Bearing Fundamentals

Thrust bearings are mechanical components designed to support axial loads, allowing smooth rotation while minimizing friction and wear. - Measurement Accuracy Challenges

Achieving high measurement accuracy in thrust bearings is crucial for precise motion control and performance optimization. Key challenges include:- Minimizing measurement errors caused by thermal effects, vibrations, and misalignments

- Developing advanced sensing technologies with improved resolution and reliability

- Integrating real-time data acquisition and processing capabilities

- Current Technological Limitations

Existing thrust bearing solutions often face limitations in terms of:- Measurement precision and repeatability under varying operating conditions

- Sensor robustness and durability in harsh environments

- Integration of multiple sensing modalities for comprehensive monitoring

- Geographic Distribution

Research and development efforts in high-accuracy thrust bearings are globally distributed, with major contributions from:- Europe (Germany, Switzerland, UK)

- North America (USA, Canada)

- Asia (Japan, South Korea, China)

Thrust Bearings Current Technical Solutions

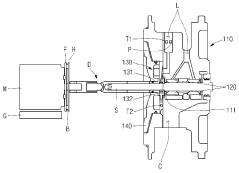

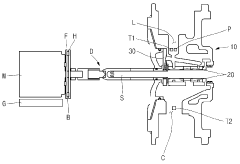

01 Thrust Bearing Structure and Components

Various thrust bearing structures and components, including bearing rings, pads, and assemblies, designed to provide support and distribute loads in applications.- Thrust Bearing Structure and Design: Various thrust bearing designs and structures to improve load-bearing capacity, reduce friction, and enhance durability, including component arrangements, specialized materials, and lubrication systems.

- Thrust Bearing Measurement and Monitoring: Methods and systems for measuring and monitoring thrust bearing parameters like wear, clearance, and temperature, aiming to improve measurement accuracy and enable real-time monitoring for predictive maintenance.

- Thrust Bearing Lubrication and Cooling: Techniques for effective lubrication and cooling of thrust bearings, including specialized lubricants, lubricant delivery systems, and cooling mechanisms, to reduce friction, wear, and temperature buildup.

- Thrust Bearing Materials and Coatings: The use of specialized materials and coatings for thrust bearings, such as ceramics, composites, and surface treatments, to improve wear resistance, load-bearing capacity, and overall performance.

- Thrust Bearing Applications and Integration: Various applications and integration methods for thrust bearings, including their use in machinery, turbines, and rotating equipment, covering design considerations and installation procedures for optimal performance.

02 Thrust Bearing Measurement and Monitoring

Methods and systems for measuring and monitoring thrust bearing performance, such as bearing clearance, wear, and temperature, to assess condition and improve accuracy.Expand Specific Solutions03 Thrust Bearing Lubrication and Cooling

Techniques for lubricating and cooling thrust bearings, including lubricant supply systems, cooling channels, and heat dissipation mechanisms, to enhance performance and longevity.Expand Specific Solutions04 Thrust Bearing Materials and Coatings

The use of materials and coatings like ceramics, composites, and surface treatments in thrust bearings to improve wear resistance, load-bearing capacity, and overall performance.Expand Specific Solutions05 Thrust Bearing Applications and Design Considerations

Specific applications and design considerations for thrust bearings, including use in turbines, compressors, and rotating machinery, addressing factors like load capacity, speed, and operating conditions.Expand Specific Solutions

Thrust Bearings Key Players Analysis

The thrust bearing technology market has witnessed significant advancements, with key players operating across various stages of maturity and technological readiness. Established corporations like NTN Corp., BorgWarner, Inc., and Danfoss A/S have demonstrated expertise, while emerging players like Nakanishi Metal Works Co., Ltd., Hyundai WIA Corp., and Vitesco Technologies GmbH contribute to innovation. Academic institutions drive research efforts, fostering collaboration with industry leaders. The market size and growth potential remain substantial, fueled by increasing demand for high-precision applications across diverse sectors.

NTN Corp.

BorgWarner, Inc.

Thrust Bearings Core Patents And Literature Review

- A first temperature sensor and a pressure sensor are installed at the front end of an oil supply hole of the thrust bearing to measure temperature and pressure of the oil supplied to the thrust bearing.

- A second temperature sensor is installed at the front end of an oil discharge hole to measure the temperature of the oil discharged from the thrust bearing.

- The apparatus allows for measuring friction loss of the thrust bearing by varying the axial load and rotational speed, enabling the design of high-performance thrust bearings.

Thrust Bearings High Accuracy Measurement Principles

Thrust bearings with high measurement accuracy are essential components in various precision engineering applications, such as machine tools, turbines, and aerospace systems. These bearings are designed to support axial loads while minimizing friction and wear, ensuring smooth and precise rotational motion.

The principles behind achieving high measurement accuracy in thrust bearings revolve around advanced sensing technologies and sophisticated control systems. Capacitive or inductive sensors are often employed to detect minute displacements or deformations within the bearing assembly, enabling real-time monitoring and adjustment of the bearing's position and preload. Additionally, active control systems can dynamically compensate for external disturbances or thermal effects, maintaining optimal operating conditions for the bearing.

Another critical aspect is the integration of high-precision manufacturing techniques, such as ultra-precision grinding and lapping processes, to ensure the bearing surfaces meet stringent flatness and roughness requirements. Advanced materials, including ceramics and specialized coatings, are also utilized to enhance wear resistance and thermal stability, further contributing to the overall measurement accuracy and longevity of the bearing system.

Thrust Bearings High Accuracy Measurement Regulatory Compliance

Thrust bearings with high measurement accuracy are essential components in various industrial applications, such as precision machinery, aerospace, and automotive industries. These bearings are designed to support axial loads while minimizing friction and wear, ensuring smooth and efficient operation.

The demand for high measurement accuracy in thrust bearings stems from the need for precise positioning, reduced vibration, and extended service life. Accurate measurements enable effective monitoring and control of bearing performance, facilitating timely maintenance and minimizing downtime. Regulatory compliance also plays a crucial role, as industries must adhere to stringent safety and quality standards.

Achieving high measurement accuracy in thrust bearings requires advanced sensing technologies, robust data acquisition systems, and sophisticated signal processing techniques. Ongoing research efforts focus on developing innovative measurement methods, such as optical encoders, capacitive sensors, and strain gauge-based systems, to enhance accuracy and reliability. Additionally, the integration of smart sensors and real-time data analysis algorithms further improves measurement precision and enables predictive maintenance strategies.